Remote particle counting supports multiple wireless transmission methods, a built-in 8GB large-capacity storage card, data can be queried using a USB interface, and it also supports on-screen query of historical data and active reporting protocol of wireless LAN.

Powerful Functions

- Remote air particle counter can measure 6 particle sizes, namely 0.3μm/ 0.5μm/ 1.0μm/ 2.5μm/ 5.0μm/ 10μm.

- This handheld airborne particle counter equipped with a variety of sensors, it can detect pressure difference temperature, and humidity.

- The online particle counter can be connected to the local area network through the network port, and the data can be uploaded to the host computer or connected to the MES system data for display on the enterprise dashboard.

Easy to Use

- 480*480 color LCD display, capacitive touch screen, more stable data collection.

- Built-in 5200 mAh battery, can work continuously for 4 hours, standby time up to 24 hours, charging only takes 2 hours.

- USB TYPE-C interface for charging, debugging, and upgrading, equipped with an environmentally friendly flame-retardant plastic shell.

Applications

The particle counter is a precision instrument used to measure the number and size distribution of suspended particles in the air. The application of particle counters not only improves production efficiency and product quality, but also helps to protect the health and safety of workers, and also plays a positive role in environmental protection. It has a wide range of applications in many fields.

Dust Free Workshop

Epidemic Prevention Station

Laboratory

Clean Room

| Model | SISCO-PC-TP505V1 | |

| Power Input | Voltage | DC 5V |

| Power Supply Voltage | DC 3.3V | |

| Current | 1.5A | |

| Haring Interface | TYPE-C | |

| External Sensor Interface | Interface Type |

12C Temperature range: -20~60℃, Accuracy ±0.5 (0~50℃), Other ±0.5℃ Humidity range: 0-100%RH, Accuracy ±2%RH (20%~80%), Other±3%RH |

| Temperature and Humidity | 4-core Aviation Head | |

| Power Supply Voltage | DC 3.3V (12V optional) | |

| Wind Speed/ Noise/ Other Gas Sensor (optional) | 5-core Aviation Head | |

| Interface Type | RS485 | |

| Data Transmission Mode | Wireless Comunication | 2G, 4G, WIFI (optional) +ZGBEE/THREAD |

| Wired Communication | RJ45 | |

| Particle Measuring Parameter | Particle Measuring Range |

0.3~10μm (0.3μm,0.5μm,1.Oμm, 2.5μm, 5.0μm, 10μm), Accuracy: 5% Resolution: 1mg/m |

| Particle Range | 200000 particles/L | |

| Pressure Sensor Measuring Parameter | Pressure Range | -500 to +500 Pa 1/4 include pagoda interface |

| Error Range | 1%, Accuracy: ±5Pa | |

| Monitor Cycle Time | 1~60MIN (Adjustable) | |

| Hardware Features | Environmentally friendly flame-retardant plastic shell | |

| USB TYPE-C interface for charging, debugging, and upgrading | ||

| Power Switch Indicator | ||

| Capacitive Touch Screen | ||

| 480*480 Color LCD Display | ||

| 8G Storage | ||

| Drawer SIM Slot | ||

| SMA Antenna Connector | ||

| Standby Status 200MA | ||

| Particles measure starts 550MA | ||

| Software Features | 4G, LAN network connection platform, WTFI local area network server | |

| Support Thread, Zigbee, and Lora wireless LAN upload data | ||

| Large-capacity history storage, 8GB built-in storage | ||

| Support USB query data (TP assistant) | ||

| Support for querying historical data on the screen | ||

| 4G and network cable interfaces support MODBUS RTU protocol to connect to the cloud platform | ||

| The network port supports the Modbus TCP server function | ||

| And Modbus RTU connection server | ||

| Active report protocol of wireless LAN uses Modbus protocol to report actively | ||

| Working Environment | -10℃~60℃, 0%~95%RH | |

| Storage Environment | -20℃~65℃, 30%~80%RH | |

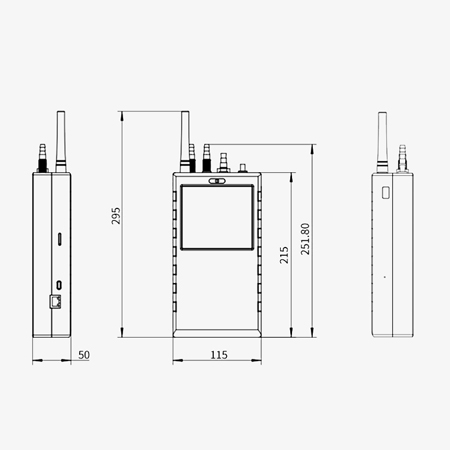

| Dimensions | 215mm×114mm×48mm | |

| Weight | 800g | |

Structure Diagram

- External Antenna Port

- Dew Point Temperature Sensor

- Expandable Sensor

- Temperature and Humidity Sensor

- Status Indicator

- SIM Card Slot

- TYPE-C Interface

- RJ45 Network Port

- Differential Pressure Sensor

- Dust Particle Sensor

- Power Button

- Color LCD Touch Screen

- Battery Compartment

Q1: How to use the handheld particle counter?

A1: The particle counter is simple to use, first determine the number of test points according to the area of the clean room and distribute the test points evenly in the clean room, then set the measurement time, measurement unit, flow rate, and other parameters of the particle counter, then put the particle counter on the plane of 1~1.2 meters height from the ground in the middle of the sampling point, and finally start to test the sampling and record the data one by one.

Q2: How to change the printing paper of the particle counter?

A2: Generally, the printing part of the particle counter has a cover, some covers can be lifted directly to cover, lift it to replace the printing paper, and some need to use a screwdriver to unscrew the screw, the specific instructions are also introduced, open the cover to follow the thermal printing paper can be replaced.

Q3: How to read the dust particle counter?

A3: The results of the dust particle counter, generally the left column is the particle diameter, and the right column is the number of particles per cubic meter.

Tips: What Circumstances Does The Probe of a Particle Counter Need to be Replaced?

A particle counter is a device used to measure the number of suspended particles in the air. It is widely used in clean rooms, hospital operating rooms, laboratories, and other environments. The probe is a very critical component in a particle counter. Its accuracy and reliability directly affect the accuracy of the measurement results. The following are some situations in which the probe of a particle counter may need to be replaced:

The probe is damaged. Long-term use may cause the probe to be contaminated by dust, oil, or other pollutants. There may also be wear or damage to the probe, or even physical damage such as installation and fading, which will affect its performance and measurement accuracy.

The detection signal is weakened. The signal strength displayed by the particle counter is significantly weakened, which may be due to aging or damage to the probe. At this time, it needs to be replaced.

Frequent calibration deviation or excessive deviation. During regular calibration, if it is found that the probe cannot pass the calibration test or the measurement results significantly deviate from known standards or historical data, it may indicate that the performance of the probe has deteriorated and needs to be replaced. Reaching the service life. At this time, according to the manufacturer's recommendations, the probe has a certain service life and should be replaced after expiration.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.