The digital particle counter can be directly connected to the computer to export the table, and the monitoring data can be recorded in time and printed without downloading software. It is suitable for various scenarios where dust particle concentration needs to be detected.

Complete Functions

- Airborne particle counter can measure 3 particle sizes at the same time: 0.3μm, 2.5μm, and 10μm, and can measure from 10,000 to 1 million.

- Portable air particle counter set two detection modes: particle counting detection PC/L and dust concentration detection ug/m3.

- Dust particle measuring device equipped with memory mode, you can view historical detection values.

Easy to Use

- LCD display allows clear reading even in dark environments.

- Portable handheld design, lightweight, easy to carry for outdoor detection.

- This handheld particle counter does not need to download software, plug directly into the computer table to read the value.

Applications

The particle counter is a precision instrument used to measure the number and size distribution of suspended particles in the air. The application of particle counters not only improves production efficiency and product quality, but also helps to protect the health and safety of workers, and also plays a positive role in environmental protection. It has a wide range of applications in many fields.

Dust Free Workshop

Epidemic Prevention Station

Laboratory

Clean Room

| Model | SISCO-PC-MKS800 |

| Particle Size Channel | 0.3/2.5/10 μm Three Grades of Particles at The Same Time |

| Sampling Time | ≈60s |

| Traffic | 1.0 L/min |

| Working Temperature | 0~50℃ |

| Humidity | 10 to 90RH |

| Resolution | lug/m3 |

| Concentration Test | PM2.5/PM10 |

| Output Range | 0-1000ug/m3 |

| Dimensions | 190mm×68.5mm×33mm |

| Weight | 220g |

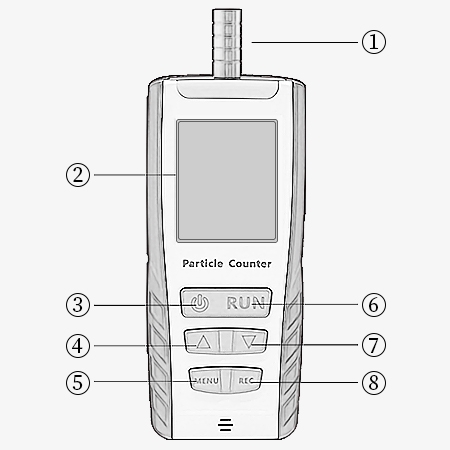

Structure Diagram

- Sampling Port

- LCD Monitor

- Power Button: Open key/return key

- “On” Button: Particle counting model

- “MENU” Button: Setting function operations

- “RUN” Button: Test

- “DOWN” Button: Concentration test mode

- “REC” Button: Viewing historical data

Q1: How to use the handheld particle counter?

A1: The particle counter is simple to use, first determine the number of test points according to the area of the clean room and distribute the test points evenly in the clean room, then set the measurement time, measurement unit, flow rate, and other parameters of the particle counter, then put the particle counter on the plane of 1~1.2 meters height from the ground in the middle of the sampling point, and finally start to test the sampling and record the data one by one.

Q2: How to change the printing paper of the particle counter?

A2: Generally, the printing part of the particle counter has a cover, some covers can be lifted directly to cover, lift it to replace the printing paper, and some need to use a screwdriver to unscrew the screw, the specific instructions are also introduced, open the cover to follow the thermal printing paper can be replaced.

Q3: How to read the dust particle counter?

A3: The results of the dust particle counter, generally the left column is the particle diameter, and the right column is the number of particles per cubic meter.

Tips: Factors Affecting Particle Counter Accuracy

There are many factors that affect the accuracy of particle counters, and understanding and controlling these factors can significantly improve the measurement accuracy of particle counters. First, it is very important to calibrate the particle counter regularly to ensure the accuracy of its measurement results. If the instrument is not properly calibrated, it may cause the measurement data to deviate from the true value. Secondly, the sampling flow rate of the particle counter directly affects the number of particles it can detect. A flow rate that is too low may not accurately reflect the particle concentration in the air, while a flow rate that is too high may cause the detection channel to be blocked. In addition, different particle counters are designed to detect particles of different size ranges. When selecting an instrument, users should determine the appropriate particle size detection range based on actual needs.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.