Surface Roughness Testers

Digital Portable Contact Surface Roughness Gauge

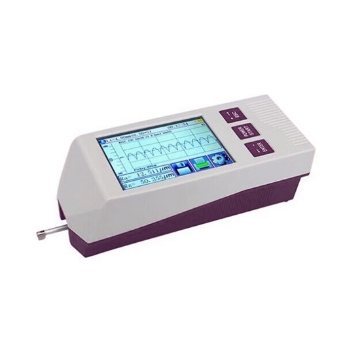

Digital Profilometer Surface Roughness Tester

Handheld Digital Surface Roughness Tester

LCD Handheld Surface Roughness Meter

Pocket Surface Roughness Tester

Portable Contact Profilometer Surface Roughness Gauge

Portable Surface Roughness Meter for Metal/ Plastic

Digital Surface Roughness Tester with LCD Display

Split-type Surface Roughness Tester

Mini Digital Surface Roughness Meter

A surface roughness tester is an instrument used to measure the surface roughness of an object. It can accurately reflect the degree of unevenness of the surface of an object. The principle of the surface roughness meter is based on the change in surface height. The roughness is determined by measuring the surface ups and downs. In industrial production and scientific research, surface roughness meters are widely used. They play a vital role in ensuring product quality and improving production efficiency.

Working Principle of Surface Roughness Tester

The principle of the surface roughness meter mainly includes two aspects, the measurement of surface height and the calculation of roughness parameters. First, the surface roughness meter receives the height information of the object surface through the sensor and then converts this information into electrical signals and transmits it to the data processing system. The data processing system will analyze and process the received signals and calculate the surface roughness parameters such as Ra, Rz , etc. through mathematical models. These parameters can objectively describe the roughness of the object surface and provide a basis for subsequent quality control and improvement.

The measurement principle of the surface roughness meter is based on the change of surface height. When the surface roughness meter detects surface fluctuations, the sensor will generate corresponding signals and transmit these signals to the data processing system. The data processing system will sample and analyze these signals, and then calculate the surface roughness parameters according to certain algorithms. These parameters can intuitively reflect the unevenness of the object surface and provide important reference data for engineers and researchers.

Classification and Types of Surface Roughness Meter

According to different measurement methods, roughness measuring instruments can be divided into two categories: contact measurement and non-contact measurement. In contact measurement, there are mainly comparison method, impression method, stylus method, etc.; in non-contact measurement methods, commonly used methods include light section method, real-time holography method, speckle method, astigmatism measurement method, optical heterodyne method, AFM, optical sensor method, etc. Among them, the stylus surface roughness measuring instrument is the most commonly used, most convenient and most reliable surface roughness measuring instrument, and has always been the basis for the formulation of national standards and international standards in various countries.

Application of Surface Roughness Instrument

- Mechanical Engineering

In mechanical engineering, surface roughness testers are widely used in the manufacturing and assembly of parts. It can help engineers measure parameters such as the geometry, size and surface quality of the surface of parts to ensure the quality and accuracy of parts.

- Automobile Manufacturing

In the automotive manufacturing process, surface roughness testers can be used to measure the surface roughness of parts such as car bodies, engine parts and wheels. This helps determine the gaps between various parts, thereby ensuring the appearance and performance of the vehicle.

- Construction Engineering

In construction projects, surface surface roughness meters can help engineers measure the surface quality of building materials, including cement, concrete, bricks and tiles. This helps ensure the fit between building materials, thereby improving the quality and durability of buildings.

- Chemical Industry

In the chemical industry, surface surface roughness meters are used to measure the surface roughness of equipment such as pipes, valves and containers. This helps ensure that the connections between equipment are tight and reduce the risk of leakage.

Roughness measurement is a measurement method used to describe the degree of height of an object's surface. A surface roughness meter is a device that directly obtains the surface roughness data of an object. The steps for using a surface roughness meter are relatively simple, but you must be careful when measuring to ensure that the surface of the object is in full contact with the surface of the measuring table , otherwise it will lead to measurement errors. When using a surface roughness meter for measurement, be sure to read the surface roughness meter manual carefully and operate it correctly according to the manual. Contact SISCO if you have any question, we will apply you as soon as posible!