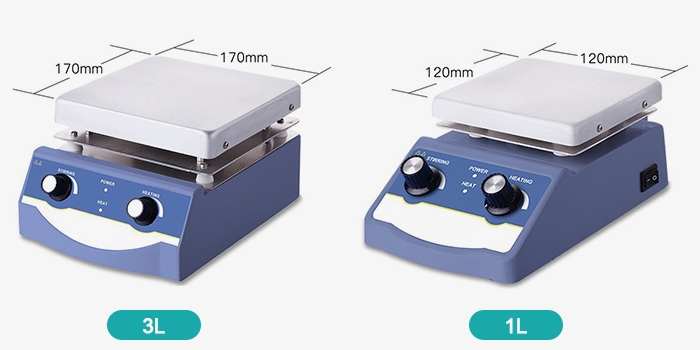

SISCO’s new magnetic hotplate stirrer features a max heating temperature of 300°C or 350°C (depending on the model). The magnetic stirrer's aluminum alloy heating plate is not only sleek and durable but also provides fast and even heat distribution. Two working surface options are available—12*12cm (1L) and 17*17cm (3L)—providing ample, stable space for placing lab glassware, minimizing vibration, and ensuring reliable operation during experiments.

Strong Magnetic Stirring Power

- Built with high-performance magnetic materials, the heated magnetic stirrer generates uniform and powerful magnetic fields, ensuring smooth, consistent stirring with no dead zones.

- The innovative magnetic circuit design of the magnetic mixer reduces magnetic decay, maintaining high stirring efficiency even during extended operation.

- The shock-absorbing construction creates a quiet lab environment, enhancing user comfort during high-speed stirring.

- Integrated overheat protection of the magnetic hotplate stirrer shuts down power automatically when the temperature exceeds safety limits, ensuring laboratory safety.

Aluminum Alloy Heating Plate

- This magnetic stirrer's surface is made from high-purity aluminum alloy with anti-corrosion treatment, and the magnetic heating plate is durable, smooth, and long-lasting.

- Optimized thermal path design ensures rapid and even heat transfer, preventing localized overheating and protecting sensitive samples.

- Smooth surface with waterproof and dustproof design, ideal for complex and demanding laboratory environments.

Applications

Magnetic stirrers are widely used in scientific and industrial settings such as university labs, chemical engineering, biopharmaceuticals, and clinical laboratories. In research and education, they enable hands-free mixing for experiments and training. In chemical and pharmaceutical fields, magnetic hotplate stirrers offer precise control of temperature and speed, ideal for synthesis, titration, and reagent preparation. In clinical labs, they help maintain consistent stirring of diagnostic samples, ensuring accurate and repeatable results. These versatile tools enhance efficiency, consistency, and reliability across a range of applications.

Chemical Engineering

Biopharmaceuticals

Medical & Healthcare

University Research

| Model | SISCO-MS-HS-12 | SISCO-MS-HS-17 |

| Functions | Heating & Stirring | |

| Control Method | Dual rotary knobs | |

| Heating Power | 180W | 500W |

| Voltage | AC 220V or 110V | |

| Max Stirring Volume | 1L | 3L |

| Speed Range | 0–1600 rpm | |

| Display | None | |

| Digital Temperature Control | None | |

| Working Plate Size | 12×12 cm | 17×17 cm |

| Working Plate Temperature | Room temperature~280°C | Room temperature~300°C |

| Working Plate Material | Aluminum alloy plate | |

| Weight | 2.3 kg | 3.75 kg |

Details

Q1: What is the primary function of a heated magnetic stirrer?

A1: A heated magnetic stirrer is laboratory mixing equipment designed for precise temperature control and uniform liquid mixing. Commonly used in lab settings, it utilizes a magnetic field to rotate a magnetic stir bar within a vessel, ensuring thorough mixing while simultaneously applying heat to maintain a constant temperature. This equipment is ideal for applications such as chemical reactions, sample dissolution, and biological incubation.

Q2: What types of containers are suitable for use with a lab magnetic stirrer?

A2: Compatible containers should be made of heat- and magnet-resistant materials like glass, stainless steel, or PTFE (Teflon). The bottom of the vessel should be flat and in full contact with the magnetic hotplate surface to ensure effective heating and stirring. Avoid using non-ferromagnetic containers such as aluminum or copper, as well as uneven or coated bottoms, which may interfere with heat transfer and magnetic coupling.

Q3: How to choose the right magnetic stir bar for a heated magnetic stirrer?

A3: Choosing the correct stirring bar for the heated magnetic stirrer depends on your specific lab application. In terms of size, the stir bar should typically be 1–2 cm shorter than the inner diameter of the container’s base to ensure smooth rotation. For shape, cylindrical bars are suitable for low-viscosity liquids, while cross or torpedo-shaped bars work better with high-viscosity fluids or larger volumes. Regarding materials, PTFE-coated stir bars offer excellent resistance to strong acids and bases, while glass or stainless steel stir bars are ideal for general-purpose mixing.

Tips: Safety Guidelines for Using a Magnetic Hotplate Stirrer

- Burn Prevention: The surface of a magnetic hotplate stirrer can reach very high temperatures during operation. Avoid direct contact with hands. Use heat-resistant gloves or tools, and ensure any built-in vents are not obstructed to prevent overheating.

- Dry Heating Prevention: Always ensure that the container has a sufficient amount of liquid (at least 2 cm covering the bottom) before heating. Dry running or low liquid levels can damage the unit or cause fire hazards. For long-term heating tasks, choose models with liquid level monitoring.

- Corrosion Resistance: When handling corrosive liquids such as strong acids, alkalis, or solvents, use corrosion-resistant vessels and Teflon-coated stir bars to prevent metal parts from coming into contact with the liquids.

- Splash Protection: When the magnetic stirrer is used during high-speed mixing, liquids may splash out of the container. Use vessels with baffles or reduce the stirring speed. For flammable or volatile substances, operate the magnetic stir plate under a fume hood and away from any ignition sources.

- Power Safety: When the device is not in use, under maintenance, or in the event of abnormal conditions (e.g., strange smell or smoke), immediately turn off the power and unplug the unit. Regularly inspect the power cord for wear or damage to avoid electric shock risks.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.