The SISCO mini magnetic stirrer is designed to operate under a wide temperature range (5–40°C) and humidity conditions (≤80% RH), ensuring reliable performance in various laboratory environments. The clockwise stirring direction aligns with everyday lab habits, and its IP42-rated enclosure offers effective dust and splash resistance. It accommodates magnetic stir bars ranging from 20–30 mm, meeting various mixing requirements. Lightweight and compact, this portable magnetic stirrer is widely used in laboratories, petrochemical sites, academic institutions, and environmental monitoring stations, making it a practical solution for both research and industrial fields.

Simple Yet Durable Mixing Platform Design

- Precision-Centered Placement: The minimalist top plate design of this laboratory magnetic stirrer features a clearly marked center point, allowing beakers to be precisely positioned for optimal stirring performance.

- Black Crystal Glass Panel: Crafted with high-quality black crystal glass, the stirring plate is stylish, structurally reinforced, and easy to clean.

- Stable Performance: Even at high speeds, our mini lab magnetic mixer operates steadily without magnetic stir bar jumping, ensuring accuracy and consistency in experiment results.

Anti-Slip, Low-Noise, and Vibration-Absorbing Base

- Anti-Vibration Feet: Four carefully placed anti-slip pads at the bottom effectively absorb shock, keeping the magnetic mixer firmly in place and secure during operation.

- Quiet Operation: Designed with advanced noise reduction technology, this low-noise laboratory magnetic stirrer maintains a quiet environment, even at high speeds.

- One-Touch Operation: The simplified interface supports quick startup and smooth operation, enhancing lab efficiency.

Stepless Speed Control with USB Connectivity

- Stepless Speed Adjustment: The adjustable rotary knob allows users to set the stirring speed anywhere between 200–1800 rpm, providing flexible control over mixing intensity.

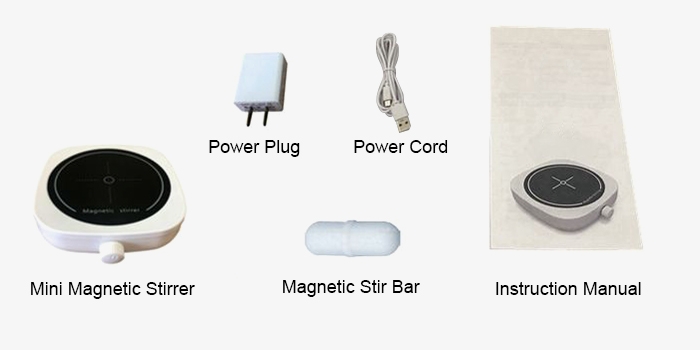

- USB Power Connection: This mini magnetic stirrer comes with a USB plug that can connect directly to a PC or power bank.

- Portable and Practical: Thoughtfully designed for usability and adaptability, this magnetic stir is an excellent choice for researchers, lab technicians, and experiment hobbyists alike.

Applications

Magnetic stirrers are widely used in scientific and industrial settings such as university labs, chemical engineering, biopharmaceuticals, and clinical laboratories. In research and education, they enable hands-free mixing for experiments and training. In chemical and pharmaceutical fields, magnetic hotplate stirrers offer precise control of temperature and speed, ideal for synthesis, titration, and reagent preparation. In clinical labs, they help maintain consistent stirring of diagnostic samples, ensuring accurate and repeatable results. These versatile tools enhance efficiency, consistency, and reliability across a range of applications.

Chemical Engineering

Biopharmaceuticals

Medical & Healthcare

University Research

| Model | SISCO-MS-PRO | |

| Control Method | Rotary knob speed control | |

| Top Plate Size | 116 mm | |

| Motor Type | Micro motor / Brushless motor | |

| Maximum Stirring Volume | 1L | |

| Speed Range | 200–1800 rpm | |

| Magnetic Stir Bar Size Range | 20–30 mm | |

| Rotation Direction | Clockwise | |

| Enclosure Protection Rating | IP42 | |

| Power | 5W | |

| Voltage | 220V 50Hz / 110V 60Hz | |

| Permissible Operating Temperature | 5–40°C, up to 80% RH | |

| Product Dimensions | 116*116*35 (mm) | |

| Package Dimensions | 210*160*60 (mm) | |

| Weight | 0.46 kg | |

Note: This product does not have a heating function; it is for stirring only.

Details

Packing List

Q1: What should I pay attention to when using this magnetic stirrer?

A1: When using this mini magnetic stirrer, especially with an Erlenmeyer flask, place the stir bar into the container before starting the unit. If the power suddenly stops during use, check whether the power cord or plug has come loose. If you notice unstable or off-centered stirring, adjust the clamp or support stand to align the stir rod correctly. Proper positioning ensures smooth operation and protects both the digital stirrer and your labware.

Q2: What is the difference between a magnetic stirrer and an overhead stirrer?

A2: The magnetic stirrer uses a rotating magnetic field to spin a stir bar inside the container, making it ideal for low- to medium-viscosity liquids and smaller volumes. In contrast, an overhead stirrer features a motorized shaft that directly agitates the solution, suitable for mixing high-viscosity materials or large volumes. Magnetic stirrers are compact, quiet, and convenient, while overhead stirrers provide higher torque and more robust mechanical mixing.

Q3: How long can a magnetic stirrer run?

A3: Most digital magnetic stirrers or mini lab stirrers are designed for continuous operation and can run for several hours or even overnight, depending on the model and application. However, it’s recommended to check the manufacturer’s guidelines for maximum runtime to prevent motor overheating. For extended use, ensure proper ventilation and avoid overloading the stir bar.

Tips: Why is my magnetic stirrer not stirring?

There are several reasons a magnetic stir plate might not stir effectively:

- The stir bar may not be centered, or may be too small or too large for the container.

- The base may be uneven, or the vessel might not be aligned with the center of the magnetic field.

- Magnetic interference (e.g., from a metal container) can disrupt function.

- For digital magnetic stirrers, incorrect speed settings or motor failure could also be the cause.

Ensure you're using compatible glassware (such as borosilicate glass) and properly positioning the vessel.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.