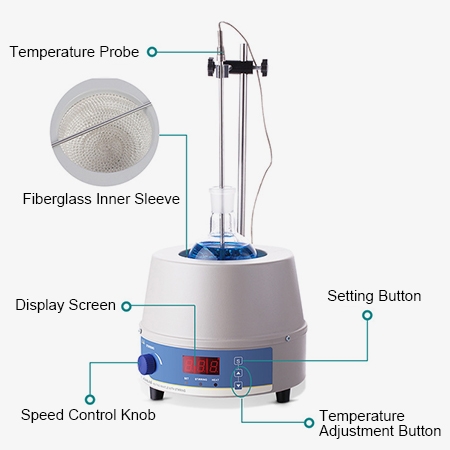

A heating mantle is a commonly used laboratory heating device, composed of a semi-spherical inner heating liner made from alkali-free glass fiber and metal heating wire, combined with a precision control circuit. It is widely used in scientific experiments for accurately and uniformly heating glass containers such as flasks and beakers. Our lab heating mantle with magnetic stirrer features a semi-spherical heating element made from alkali-free glass fiber and high-quality heating wire. With fast heating speed, high temperature capacity, and ease of use, the digital heating mantle is a durable and reliable tool for precise temperature-controlled experiments in glass containers.

Durable and Protective Housing

- Integrated Mold Design for Better Heat Efficiency: The outer shell is formed through one-time compression molding and coated with electrostatic spray for enhanced corrosion resistance and anti-aging properties. Over 60% of the surface efficiently conducts heat.

- Modern Design, User-Friendly Interface: The sleek, ergonomic design of the heating mantle with stirrer provides a pleasant user experience and excellent performance for any lab setup.

- Enhanced Safety Features: Smoothly polished edges eliminate sharp corners, reducing the risk of injury during operation. The outer housing is impact-resistant to protect internal components from accidental damage—ideal for safe laboratory environments.

High-Efficiency Heating Core

- Fast Heating, Stable Temperature Maintenance: The optimized heating mantle core ensures rapid temperature rise and excellent heat retention, maintaining temperature stability throughout experiments.

- Alkali-Free Glass Fiber Inner Container: The inner insulation uses alkali-free glass fiber, embedded with alloy wire springs and vacuum-shaped with aluminum silicate cotton for high durability. It supports temperatures up to 300°C, making it both heat-resistant and corrosion-resistant.

- Efficient Heat Dissipation: The bottom features a multi-hole ventilation design for quick heat release, ensuring safe and uninterrupted performance.

Intelligent Control Panel

- LED Digital Display for Easy Monitoring: Equipped with a digital LED control panel, this lab heating mantle displays real-time temperature readings clearly, allowing precise adjustments.

- Electronic Temperature Regulation: The temperature-controlled magnetic stirrer uses electronic regulation to maintain a consistent heating environment, ideal for achieving accurate and repeatable experimental results.

- Adjustable Stirring Speed: The built-in powerful magnetic stirrer offers adjustable speed control via a user-friendly knob, delivering uniform stirring and maximum efficiency for a variety of mixing tasks.

Applications

Magnetic stirrers are widely used in scientific and industrial settings such as university labs, chemical engineering, biopharmaceuticals, and clinical laboratories. In research and education, they enable hands-free mixing for experiments and training. In chemical and pharmaceutical fields, magnetic hotplate stirrers offer precise control of temperature and speed, ideal for synthesis, titration, and reagent preparation. In clinical labs, they help maintain consistent stirring of diagnostic samples, ensuring accurate and repeatable results. These versatile tools enhance efficiency, consistency, and reliability across a range of applications.

Chemical Engineering

Biopharmaceuticals

Medical & Healthcare

University Research

| Model | SISCO-MS-HMSC | |||||||

| Capacity | 100mL | 250mL | 500mL | 1000mL | 2000mL | 5000mL | 10000mL | 20000mL |

| Heating Power | 100W | 150W | 250W | 350W | 450W | 800W | 1200W | 2400W |

| Max Temperature | Room Temperature~300℃ | |||||||

| Function | Heating & Magnetic Stirring | |||||||

| Temperature Control | Digital Temperature Control | |||||||

| Stirring Speed | 0-1400 rpm | |||||||

| Power Supply | 220V AC or 110V AC | |||||||

| Size | 23*23*20cm | 23*23*20cm | 23*23*20cm | 30*30*24cm | 32*32*27cm | 37*36.5*30cm | 43*42.5*35.5cm | 51*50.5*38cm |

| Weight | 2.4kg | 2.8kg | 2.9kg | 4.4kg | 5.3kg | 8kg | 12.1kg | 18.6kg |

Details

Q1: What containers can be used with a digital heating mantle?

A1: A digital heating mantle with magnetic stirrer is primarily designed for use with glass containers such as beakers and round-bottom flasks. The magnetic stirring function requires the container to have a flat bottom and be made of materials that allow magnetic field penetration, such as standard or borosilicate glass. Metal containers are not recommended, as they can interfere with the magnetic field and pose safety risks.

Q2: How to choose the right size heating mantle?

A2: When selecting a lab heating mantle, you should base the capacity on the size of the glassware commonly used in your experiments. It's generally advised that the container volume should not exceed two-thirds of the mantle’s rated capacity to ensure even heating and prevent spillage. For instance, if you frequently use a 500 mL flask, a 1000 mL heating mantle is recommended.

Q3: How to clean and maintain a magnetic stirrer heating mantle?

A3: After switching off the power and allowing the magnetic stirrer hotplate to cool completely, clean the exterior and heating surface with a soft cloth and mild detergent. Avoid using sharp objects that could scratch or damage the inner lining made of alkali-free fiberglass. For long-term storage, keep the device in a dry, well-ventilated area to maintain performance and durability.

Tips: What are the different types of heating mantles?

There are several types of heating mantles, including:

- Basic heating mantles – for simple heating tasks without stirring.

- Magnetic heating mantles – combine heating and magnetic stirring.

- Digital heating mantles – offer precise temperature control with LED/LCD.

- Multi-position heating mantles – allow simultaneous heating of multiple samples.

- Large-capacity heating mantles – designed for volumes up to 20L or more.

Each type serves specific needs depending on lab applications and experiment requirements.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.