This high-precision, high-sensitivity integrated rebar scanner is designed to detect rebar positions, concrete cover thickness, spacing, and diameters within concrete structures. The concrete rebar scanner can generate accurate rebar distribution maps while delivering high-speed, high-accuracy measurements. Featuring an all-in-one design with the main unit and sensor coil integrated, the rebar locator ensures easy portability and quick on-site operation. The multi-coil structure enhances detection speed, accuracy, and resolution.

Comprehensive Rebar Detection Capabilities

- Accurate measurement of rebar cover thickness to ensure compliance with construction standards.

- Precise positioning of rebars, orientation, and distribution, providing reliable data for structural design.

- Simultaneous estimation of rebar diameter while the rebar detector measures cover thickness for comprehensive detection.

- The rebar finder also supports data storage, review, and seamless transfer for efficient data management and analysis.

Flexible and User-Friendly Scanning Modes

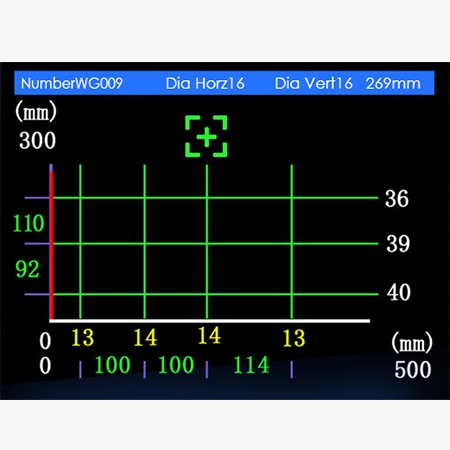

- Intuitive and precise detection modes display rebar position, spacing, and cover thickness on a single screen.

- Four scanning methods—single-point, grid, waveform, and cross-section scans—with full undo capability for erroneous data.

- Seamless X/Y-axis switching during grid scanning, maintaining continuous data flow and rebar mapping.

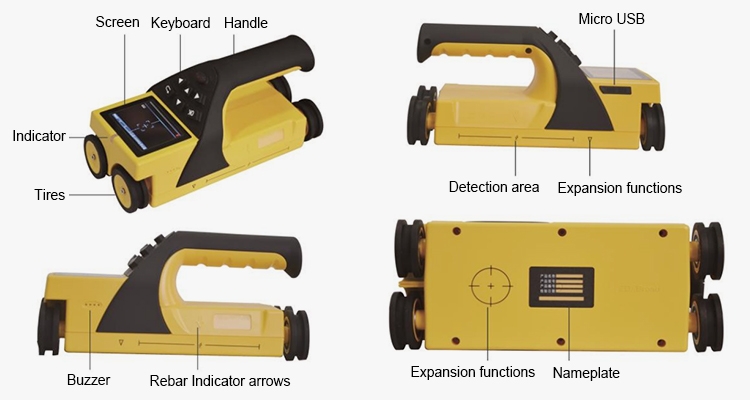

- One-handed operation with four-wheel positioning and high-durability wheels to protect against wear and tear.

- Automatic calibration storage, eliminating the need for frequent pre-measurement calibration.

High-Performance Hardware and Data Management

- This concrete rebar scanner has a 2.8-inch high-resolution color LCD (320×240 pixels) for clear visibility in all environments.

- Multi-coil structure of the rebar scanning machine for faster speed, higher accuracy, and improved resolution.

- USB data transfer and charging, enabling quick uploads to a computer.

- Built-in high-capacity lithium battery with low power consumption, providing 16+ hours of standby time.

- Extensive data storage, capable of holding up to 200,000 rebar measurement points.

- High-density rebar resolution minimizes the risk of missed detections.

- Compact and lightweight all-in-one design, integrating the main unit and sensor coil, making the rebar scanner easy to carry.

- Rebar detection software enabled professional data analysis, processing, and report generation on a PC.

Applications

The rebar scanner is widely used in reinforced concrete structure inspections, furniture wall installations, drilling rebar positioning, and electrical cable detection. In reinforced concrete inspections, the rebar detector accurately measures rebar position, spacing, and concrete cover thickness, ensuring construction quality and safety. For furniture wall installations and drilling, it helps avoid rebars, improving installation precision and reducing damage risks. In electrical cable detection, the rebar locator effectively identifies hidden cables within walls or floors, preventing accidental drilling or cutting and enhancing construction safety.

Drilling Positioning

Concrete Structure

Cable Detection

Furniture Installation

| Model | SISCO-RS-ZL910 | |

| Applicable Range of Rebar (mm) | φ6~φ50 | |

| Protective Layer of Thickness Range (mm) | Small Range: 1~80 | |

| Large Range: 5~185 | ||

| Screen | 320×240 | |

| Power Supply | Built-in High Capacity Lithium Battery | |

| Working Hours | ≥16h | |

| Communication | USB Interface | |

| Storage | 200K Measuring Point of Steel Bar | |

| Operation | Silicone Keypad | |

| Size (mm) | 219*92*106 | |

| Working Temperature | -10℃~+50℃ | |

| Relative Humidity | ≤ 90% RH | |

| Weight | 0.6kg (Battery Included) | |

| Measuring Range of Different Rebar Diameters | ||

| Rebar Diameter (mm) | Small Range (mm) | Large Range (mm) |

| φ6~φ8 | 1~60 | 5~100 |

| φ10~φ18 | 1~80 | 5~120 |

| φ20~φ28 | 1~80 | 5~140 |

| φ32~φ50 | 1~80 | 5~185 |

| Error Range of Different Thickness | ||

| Error Range | Small Range (mm) | Large Range (mm) |

| ±1 | 1~59 | 5~59 |

| ±2 | 60~80 | 60~79 |

| ±3 | ... ... | 80~99 |

| ±4 | 100~185 | |

Details

Packing List

- 1* Product Host

- 1* Charger

- 1* USB Cable

- 1* User Manual

- 1* Producer Certficate

- 1* Warranty Card

- 1* Packing List

- 1* Product Suites/Box

- 1* Software CD (Limited to Different Models)

- 1* Crayon

- 1* Standard Block (Optional Accessories)

Q1: How to use the rebar scanner for detection?

A1: Choose a smooth surface whenever possible to enhance detection accuracy. If the surface is too rough, clean and level it before scanning. Select the appropriate scanning mode based on the application and set the scanning parameters, such as rebar diameter. Place the rebar detector close to the concrete surface and move it slowly and steadily. The real-time scan results will be displayed and stored automatically. After scanning, review, save, or export the stored data as needed.

Q2: What should I do if the concrete rebar scanner won’t turn on?

A2: Check if the rebar detector battery is correctly installed, ensuring the positive and negative terminals are aligned properly. Try reinstalling the battery and using another compatible power adapter to rule out adapter failure. If the concrete rebar finder still doesn’t respond, it may be a hardware issue, and you should contact customer support.

Q3: Why is the rebar detector showing large measurement errors?

A3: Measurement errors in a rebar scanner can result from several factors. Uneven concrete surfaces interfere with ultrasonic or electromagnetic signal transmission, leading to inaccurate readings. In areas with dense rebar arrangements, signals may overlap or cause interference, reducing the rebar locator’s resolution and detection accuracy. If the rebar finder is not calibrated, environmental conditions such as temperature, humidity, or sensor drift can impact precision, making regular calibration essential for high-accuracy rebar scanning. Additionally, scanning direction plays a critical role—ensure the rebar scanner moves perpendicularly to the rebar orientation to achieve the most precise detection results.

Tips: Maintenance & Care for the Rebar Scanner

- Operation: Avoid pressing buttons too hard during operation. Do not operate with oily, muddy, or wet hands, as this may shorten the keypad's lifespan.

- Power Management: The device uses a built-in rechargeable lithium battery with a 16+ hour standby time when fully charged. Monitor the battery level—if low, charge the device immediately to prevent data loss or damage from sudden shutdowns. Use only the designated battery and power supply—third-party power sources may cause battery leaks, fire hazards, or permanent device damage.

- Storage & Cleaning: Store the rebar scanner in its protective case in a cool, dry, and well-ventilated area (<90% RH). If unused for long periods, the battery will naturally discharge—charge it at least once a month and run periodic power-on checks. After each use, clean the device to prevent water, oil, dirt, or dust from entering the connectors, which could affect performance and measurement accuracy.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.