SISCO smart rebar scanner achieves a ±1mm accuracy in rebar spacing measurements and provides high-precision visualization of rebar grid distribution in both plan and cross-sectional views. This rebar finder can also detect metallic objects within non-magnetic and non-conductive materials, such as cables and plumbing pipes embedded in walls, helping prevent construction-related damage.

Key Functions

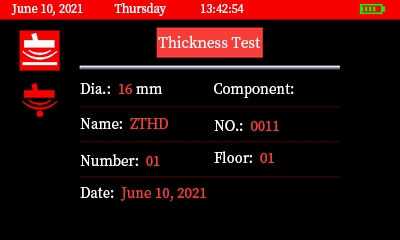

- Concrete Cover Thickness Measurement: The rebar scanning machine can accurately measure cover thickness when the rebar diameter is known; and simultaneously estimate rebar diameter and cover thickness when unknown.

- 3D Rebar Positioning: This concrete rebar finder displays real-time rebar position, orientation, and grid distribution (plan & cross-section views) with ±1mm spacing accuracy.

- Path Scanning Mode: SISCO rebar detector supports continuous scanning, quickly generating heatmaps of rebar distribution, improving detection efficiency.

- Concealed Utility Detection: Detects metallic objects within non-magnetic/non-conductive materials (e.g., cables and plumbing pipes inside walls) to reduce construction risks.

- Smart Data Management: The built-in large-capacity storage of the rebar scanner, supports on-site data review, export, and cloud transmission, compatible with mainstream engineering management software.

Technical Features

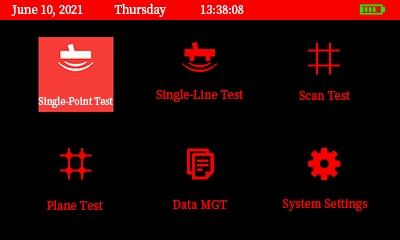

- Intuitive Display: The full-color LCD screen of this rebar locator shows real-time cover thickness and spacing data, alongside plan and cross-section rebar grid views, enhancing detection speed and visualization.

- User-Friendly Design: Silicone dustproof buttons combined with a full-color LCD, eight adjustable brightness levels, and customizable themes for varied lighting conditions.

- Environmental Calibration: Built-in environmental calibration ensures accurate data of the detector in different conditions.

- High-Precision Detection: Maintains ±1mm spacing accuracy, ensuring measurement reliability.

- Extended Battery Life: Our smart concrete rebar finder supports 12+ hours of continuous operation, meeting long-duration and high-intensity testing needs.

Applications

The rebar scanner is widely used in reinforced concrete structure inspections, furniture wall installations, drilling rebar positioning, and electrical cable detection. In reinforced concrete inspections, the rebar detector accurately measures rebar position, spacing, and concrete cover thickness, ensuring construction quality and safety. For furniture wall installations and drilling, it helps avoid rebars, improving installation precision and reducing damage risks. In electrical cable detection, the rebar locator effectively identifies hidden cables within walls or floors, preventing accidental drilling or cutting and enhancing construction safety.

Drilling Positioning

Concrete Structure

Cable Detection

Furniture Installation

| Model | SISCO-RS-ZT702 | |

| Rebar Diameter Range (mm) | φ6~φ50 | |

| Concrete Cover Thickness Range (mm) | Small Range: 6~90 | |

| Large Range: 7~200 | ||

| Communication Mode | USB Data Transfer | |

| Storage Capacity | 200,000 Rebar Measurement Points | |

| Probe | Dimensions (mm) | 110 × 55 × 28 |

| Weight (kg) | 0.25 | |

| Cart | Dimensions (mm) | 128 × 97 × 64 |

| Weight (kg) | 0.3 | |

| Telescopic Rod | Dimensions (mm) | φ40 × 525 (1.8m) |

| Weight (kg) | 0.4 | |

| Display Resolution | 800 × 480 | |

| Power Supply | Built-in High-Capacity Lithium Battery | |

| Operating Time | ≥12 hours | |

| Operating Temperature | -10℃~+42℃ | |

| Relative Humidity | <90% RH | |

| Overall Dimensions (mm) | 219 × 56 × 139 | |

| Operation Method | Silicone Button | |

| Net Weight | 0.64 kg (Battery Included) | |

| Measurement Range for Different Rebar Diameters | ||

| Rebar Diameter (mm) | Small Range (mm) | Large Range (mm) |

| φ6~φ8 | 7~70 | 10~100 |

| φ10~φ18 | 8~80 | 15~126 |

| φ20~φ32 | 9~90 | 20~200 |

| Measurement Error for Different Thickness Ranges | ||

| Error (mm) | Small Range (mm) | Large Range (mm) |

| ±1 | 6~59 | 7~79 |

| ±2 | 60~69 | 80~119 |

| ±4 | 70~90 | 120~200 |

Q1: What are the main applications of a scanning-type concrete rebar scanner?

A1: The scanning-type concrete rebar scanner is primarily used for detecting rebar position, distribution, orientation, concrete cover thickness, and rebar diameter in structures such as bridges, tunnels, and walls. Additionally, the rebar locator can detect ferromagnetic and conductive objects within non-ferromagnetic materials, such as electrical wires and pipelines.

Q2: What are the operating environment requirements for the rebar locator?

A2: This rebar detector operates in temperatures from -10℃ to +42℃ with a relative humidity of <90% RH. It should avoid strong alternating electromagnetic fields and direct or prolonged sunlight to prevent malfunctions. When used in humid, dusty, or corrosive environments, proper protective measures should be applied.

Q3: How to measure concrete cover thickness with a rebar scanner?

A3: To accurately measure concrete cover thickness using a rebar detector, position the detector’s probe between two rebars, ensuring it is parallel to the rebar being measured. Slowly move the rebar locator along the scanning path. As the scanner probe approaches the rebar, the rebar scanning machine will display the corresponding concrete cover thickness, providing precise measurement results for rebar detection in concrete structures.

Tips: Usage & maintenance of the concrete rebar scanning detector?

- Preparation Before Use: Familiarize yourself with the device's operation and precautions. Identify the approximate position, orientation, and diameter of rebars and set the correct parameters.

- Operating Techniques: Move the scanner slowly and steadily. Keep the scanning direction perpendicular to the rebar’s orientation. For mesh rebar structures, first locate the upper layer, then measure between layers to identify the lower layer.

- Data Processing: Use the device’s storage function for later data analysis. Supports USB transfer for easy upload to a computer.

- Precautions: Avoid scanning over rebar joints, binding wires, or other conductive metals. Regularly reset the probe to maintain detection accuracy. Handle the device with care to prevent mechanical damage.

- Maintenance & Care: Inspect cables and plugs for damage and replace them if necessary. Clean the device surface and probe to keep them free of dust and debris. If not used for an extended period, store them in a dry, ventilated area.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.