SISCO's new handheld high-precision rebar detector is a professional high-sensitivity magnetic induction scanner. This rebar scanner measures concrete cover thickness, locates rebar positions, estimates rebar diameters, and manually tests rebar spacing. With dimensions of just 170*78*38mm, the concrete rebar finder is compact and portable, making it an essential tool for construction professionals.

Professional All-in-One Detection

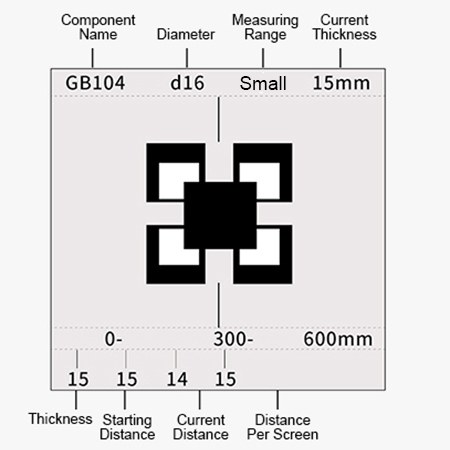

- Three-in-One Functionality: The rebar scanner can precisely locate rebars, accurately measure the concrete cover thickness (±1mm precision), and quickly estimate rebar diameters (compatible with φ6~φ50mm).

- Revolutionary Mini Probe: Ultra-compact 170*78*38mm body weighing only 280g, making the rebar detector easy to operate, and effortless to store in a tool bag.

- Intelligent Construction Assistant: Built-in professional data analysis system that supports data export to PC (compatible with Windows XP/7/8, etc.) for generating detailed inspection reports.

Six Core Technology Advantages

- HD Visual System: 128×128 resolution LCD screen with smart backlight adjustment for clear visibility in dark environments like underground garages or nighttime construction.

- Ergonomic Design: Anti-slip grip and one-button operation for quick learning—beginners master the rebar locator in just 5 minutes.

- Superior Build Quality: Rugged and durable body, impact-resistant and wear-resistant, suitable for harsh construction environments.

- Smart System Design: This rebar scanning machine helps avoid drilling into rebars, pipelines, and embedded components, extending the drill bit lifespan.

- Multi-Frequency Induction Technology: Proprietary multi-coil matrix sensor improves detection speed and enhances positioning accuracy to ±3mm.

- Extended Battery Life: The rechargeable lithium battery pack of the concrete rebar scanner supports 20 hours of continuous operation, with fast USB charging.

Applications

The rebar scanner is widely used in reinforced concrete structure inspections, furniture wall installations, drilling rebar positioning, and electrical cable detection. In reinforced concrete inspections, the rebar detector accurately measures rebar position, spacing, and concrete cover thickness, ensuring construction quality and safety. For furniture wall installations and drilling, it helps avoid rebars, improving installation precision and reducing damage risks. In electrical cable detection, the rebar locator effectively identifies hidden cables within walls or floors, preventing accidental drilling or cutting and enhancing construction safety.

Drilling Positioning

Concrete Structure

Cable Detection

Furniture Installation

| Model | SISCO-RS-ZL510 | |

| Diameter Measuring Range (mm) | φ6~φ50mm | |

| Measuring Range (mm) | Location Range: 1~120mm | |

| First Range: 1~60mm | ||

| Second Range: 30~120mm | ||

| Thickness Measuring Accuracy (mm) | 1~40mm | ±1 |

| 41~60mm | ±2 | |

| 61~80mm | ±3 | |

| 81~100mm | ±5 | |

| 101~120mm | ±8 | |

| Rebar Location Accuracy | 1~60 | ±3 |

| 61~120 | ±6 | |

| Diameter Measuring Modes | Optional | |

| JGJ Measurement | Optional | |

| Data Storage | Optional | |

| Off Time | Automatic | |

| Power Supply | Rechargeable Lithium Battery | |

| Working Temperature | -10℃~+42℃ | |

| Relative Humidity | ≤90%RH | |

| Size (mm) | 170*78*38 | |

| Net Weight | 280g | |

Details

Packing List

- 1* Product Host

- 1* Charger

- 1* USB Cable

- 1* User Manual

- 1* Producer Certficate

- 1* Warranty Card

- 1* Product Suites/Box

- 1* Software CD

Q1: How often should a rebar scanner be calibrated?

A1: To ensure accurate and reliable rebar detection, it is essential to calibrate the rebar detector before starting a new construction project or when there are significant environmental changes, such as temperature or humidity fluctuations exceeding ±10%. For frequent use (three or more times per week), calibration should be performed at least once a month. For less frequent use, calibration can be extended to once every two months, but it should never exceed three months to maintain optimal rebar scanning accuracy.

Q2: What factors may affect the rebar detector's measurement accuracy?

A2: The main influencing factors include: ① Concrete moisture content (it is recommended to avoid testing within 24 hours after rain), ② Steel bar corrosion degree, ③ The coupling degree between the probe and the detection surface (needs to be kept vertically close).

Q3: Can this rebar locator detect coated rebars?

A3: Our steel rebar scanner supports the detection of common protective layers such as epoxy resin coatings and fire retardant coatings (thickness <5mm). For magnetic coatings or thick decorative layers, it is recommended to perform local cleaning or use the mode-switching function first.

Tips: "Four-Step 3D Positioning" for Complex Structures

- Baseline Calibration: Zero-point calibration in a rebar-free area.

- Grid Scanning: Create a 50cm grid and log coordinate data.

- Cross Verification: Use an "X + star pattern" scan for intersecting rebars, taking the three-scan intersection as the final position.

- Data Integration: Import results into the software to generate a 3D rebar model, keeping errors within ±1.5mm.

This method significantly improves detection efficiency—ideal for dense reinforcement structures like bridge piers and shear walls, boosting accuracy by 40% or more.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.