The plastic pipe locator uses precision injection molds and composite injection molding technology. The body is sturdy, non-slip, and anti-fall. The waterproof probe is smooth and wear-resistant and can measure both dry and wet pipes.

Complete functions

- Electromagnetic induction principle, the transmitter probe emits electromagnetic waves, and the receiver receives electromagnetic waves. It has the advantages of not interfering with the fluid, long-distance detection, and adaptability to various flow ranges.

- The transmitter probe has a self-check function. After turning it on, the probe can automatically detect whether it is operating normally, improving work efficiency.

- Strong signal penetration, the maximum detection depth can penetrate the pipe blockage point under the 40cm thick cement wall/ floor, reducing the demolition area.

Reliable quality

- Large-capacity lithium battery, transmitter 2600mAh, receiver 1400mAh, working time can reach 10h/5h after a full charge and a double-head charging cable is used.

- The signal line is durable, the probe line is made of polymer material, the surface is smooth, can be bent, and is not easy to break.

- PVC pipe finder equipped with IP67 waterproof probe can accurately detect even in harsh environments with water, and 6 probes are standard for replacement.

Applications

This pipe detector is suitable for a variety of scenarios. It can detect metal pipes such as iron pipes, cement pipes, steel pipes, copper tubes, and non-metal pipes such as PVC pipes and plastic pipes. The pipe detector machine has good applications for blockage problems in scenes buried in cement walls, ground, and land. In short, the pipe blockage detector is an indispensable device in pipeline maintenance. It not only improves work efficiency and reduces maintenance costs, but also provides important support for ensuring the stable operation of industrial production and urban water supply systems.

Cement Pipe

Copper Tube

Wall Pipe

PVC Pipe

| Model |

SISCO-PD-NF5140

|

|

| Emitter | Tube Lamp | 40m |

| Applications | PVC/Plastic steel/copper cement/iron tube | |

| Power Supply | 18650 Lithium battery 2600mAh | |

| Maximum Detection Depth | 40cm | |

| Working Frequency | 300Hz | |

| Working Hour | 10H | |

| Working Temperature | 10~40°C | |

| Dimension | 300mmx360mmx45mm | |

| Weight | 1500g | |

| Receiver | Sensitivity Adjustment | Yes |

| Distance Range | Non-pipe pipe: 0-40cm, metal pipe: 0-15cm | |

| Power Supply | Lithium1400mAh | |

| Working Frequency | 300Hz | |

| Working Hour | 5H | |

| Working Temperature | 10~40°C | |

| Dimension | 65mmx360mmx40mm | |

| Storage Temperature | -10°C~50°C | |

| Voice Indication | Yes | |

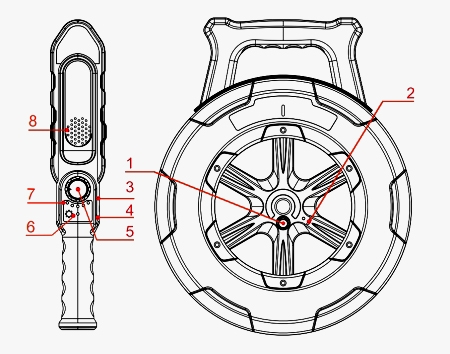

Structure Diagram

- OFF/ON

- Charging Port

- Charging Port

- Headphone Jack

- Sensitivity Adjustment

- Power Light

- Signal Light *5 Charging Port

- Horn Hole

Q1: How does a pipe detector work?

A1: Pipe blockage detectors generally use the principle of radio transmission and reception. It sends a specific signal. When encountering a blockage, the propagation of the signal will change, and the specific location of the blockage is determined by the signal change captured by the receiver.

Q2: What factors can affect pipe detectors?

A2: During use, it is necessary to consider many factors such as pipeline material, structural characteristics, external environment, fluid state in the pipeline, as well as equipment performance, and operator skill level. Through reasonable use and scientific operation, interference can be minimized and the accuracy and efficiency of detection can be improved.

Q3: How do I store a pipe detector when not in use?

A3: When the pipe blockage detector is not used for a long time, it should be stored in a dry, cool, dust-free environment, preferably in an air-conditioned room. The storage location should be away from direct sunlight and high-temperature sources to prevent the device from overheating and damage. At the same time, the device should be powered on and tested regularly to keep it in good working condition.

Tips: Notes on probe replacement

The probe of the pipe finder is a very critical component of the instrument, which is used to directly contact the pipeline medium to measure flow or detect blockage. The performance of the probe directly affects the accuracy and reliability of the measurement.

If the probe is physically damaged, such as broken, deformed, or detached, it should be replaced immediately, because the housing or sensor part of the probe will affect the measurement accuracy.

Over time, the performance of the probe may deteriorate due to wear or aging of the material, and it is time to replace it.

If the measurement results are frequently abnormal and it is suspected that the probe is a problem after excluding other reasons, the probe may need to be replaced.

After a period of use, the performance of the probe may be affected by accumulation or contamination.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.