In addition to the functions mentioned above, the SISCO mini optical power meter also features a compact design, an automatic shutdown function, a wavelength memory function, manual calibration capabilities, fiber job identification, and a wide testing range.

Precision OPM: DIY Calibration & Frequency Identification

- High-Precision Optical Power Meter: Measurement error is less than +/-0.2dB, supporting manual calibration.

- DIY Self-Calibration: Allows adjustment of testing parameters based on actual testing needs.

- Frequency Identification Function: The mini opm supports can automatically recognize and adapt to different frequencies, ensuring seamless operation across various systems.

LED Display with Multi-Wavelength & Unit Options

- LED and Backlight: Vibrant colors, high definition, and a sleek design, visible even in darkness.

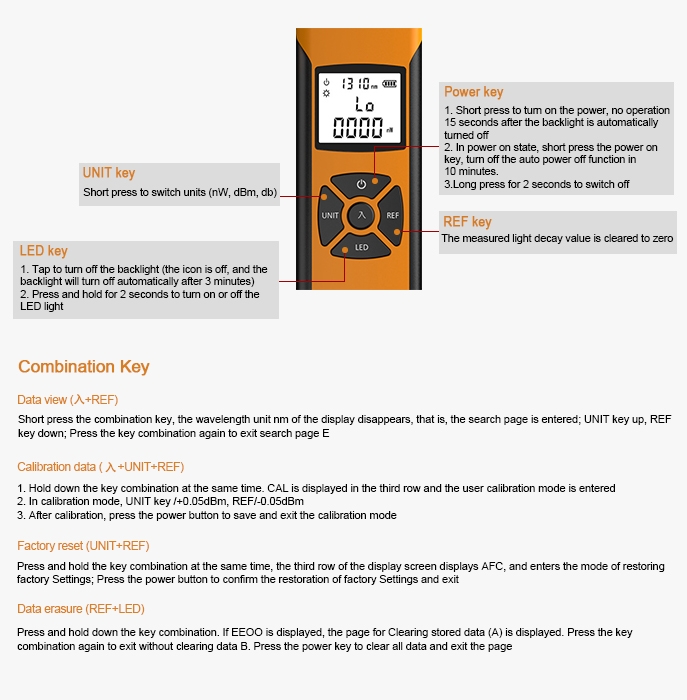

- 9 Test Wavelengths: Press the "λ" key to switch between 9 different test wavelengths.

- Two Display Units: In the powered-on state, short press to cycle through and select the display units (nW or dB). Test data will be shown in the corresponding unit.

Universal Interface, Long Battery, & Wavelength Memory

- 2.5mm Universal Interface: compatible with FC, SC, and ST fiber optic connectors, meeting various connector requirements. Users can easily replace adapter heads and ceramic ferrules.

- Large-Capacity Lithium Battery: Rechargeable lithium battery with ultra-large capacity, offering long-lasting endurance. Comes with a universal USB interface.

- Wavelength Memory Function: Thoughtful design that allows the device to remember the last used wavelength upon startup.

Applications

Fiber optical power meter can be widely used in optical cable construction and maintenance, optical fiber communication, optical fiber sensing, CATV and other fields. It is mainly used for the measurement of continuous optical signal power, optical fiber line loss test, optical device insertion loss test, optical fiber breakpoint location, end-to-end optical fiber identification, etc.

Optical Fiber Communicate

Optical Fiber Sensing

CATV

Optical Cable Const.&Maint.

| Model | SISCO-PQA-G10 |

| Wavelength Range | 800~1700nm |

| Probe Type | InGaAs |

| Measuring Range | -70~+6, -70~+10, -50~+26 |

| Uncertainty | ±5% |

| Standard Wavelength(nm) | 850/980/1270/1300/1310/1490/1550/1577/1625mm |

| Display Resolution | Lineardisplay: 0.1% Logarithmic display: 0.01dBm |

| Frequency Identification (Hz) | 270Hz, 1000Hz, 2000Hz |

| Quiescent Current | <18uA |

| Working Current | <25mA |

| Battery Working Time(h) | >20H |

| Charging Voltage | 5V |

| Recharging Current | <500mA |

| Charging Time | <3H |

| Auto off Time(min) | 10min |

| Power Supply | Rechargeable lithium battery, External input |

| Battery | 350mAh |

| Size | 126*35*16mm |

| Net Weight(g) | 52g |

Details

Packing List

- 1 x Optical Power meter

- 1 x USB cable

- 1 x Warranty card

- 1 x Certificate

- 1 x User manual

- 1 x Packing box

- 1 x Landyard

Q1: What do EN61326-1:2013 and EN61326-2-2:2013 compliance standards mean?

A1: EN61326-1:2013 and EN61326-2-2:2013 are European standards that define the requirements for electromagnetic compatibility (EMC) for electrical equipment used in industrial and laboratory environments. Compliance with these standards ensures that a device, such as a fiber optic power meter, can operate without causing or being affected by electromagnetic interference in these settings. EN61326-1:2013 covers the general requirements for all equipment, while EN61326-2-2:2013 provides additional requirements specific to test and measurement equipment, ensuring reliable and accurate performance in environments with potential electromagnetic disturbances.

Q2: Why is wavelength selection important in a fiber optic power meter?

A2: Wavelength selection is crucial in a fiber opm because different optical signals are transmitted at specific wavelengths, depending on the type of fiber and the application. Accurate measurement of the optical signal's power requires the power meter to be tuned to the correct wavelength, as signal strength can vary significantly across different wavelengths. Incorrect wavelength selection can lead to inaccurate measurements, potentially compromising the performance of the network. Therefore, having a power meter that supports a range of wavelengths ensures versatility and precision in various testing and troubleshooting scenarios within fiber optic systems.

Q3: What wavelengths do fiber optic power meter typically measure?

A3: Fiber optic power meter typically measure a range of wavelengths commonly used in fiber optic communications. The most standard wavelengths include 850nm, 980nm, 1300nm, 1310nm, 1490nm, 1550nm, 1625nm, and 1650nm. These wavelengths cover the primary bands used for data transmission in various types of optical fibers, including multimode and single-mode fibers, ensuring that the power meter can accurately measure the signal strength across different fiber optic networks.

Tips: How does a fiber optic power meter work?

A fiber optic power meter works by measuring the optical power of light transmitted through a fiber optic cable. The device uses a photodetector to capture the light signal, which then converts the optical energy into an electrical signal. This electrical signal is proportional to the power of the light entering the meter. The power meter processes this electrical signal and displays the optical power level, typically in units such as decibels-milliwatts (dBm), decibels (dB), or milliwatts (mW). The user selects the appropriate wavelength on the meter to match the wavelength of the light being measured, ensuring accurate readings. This process allows technicians to verify signal strength, troubleshoot issues, and ensure the fiber optic network is functioning correctly.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.