Fixed thermal imaging camera has a variety of lens options, and come standard with a one-button macro mode, which allows you to capture and measure tiny objects without switching lenses. The infrared imaging is clear and supports MSK image enhancement, which can be easily transmitted via WIFI.

Powerful Functions

- Infrared imaging has high sensitivity and good effect. Equipped with three modes of focus: automatic/manual/macro, and with a variety of interchangeable lenses, it ensures accurate infrared measurement results.

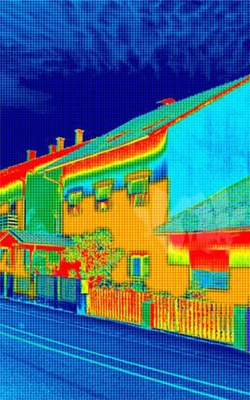

- The infrared camera equipped with MSX image enhancement technology, can more clearly distinguish the different characteristics and components of the test object, providing radiation data with excellent imaging quality.

- Measurement data analysis is convenient. Professional data processing software can analyze, share, and collaborate on the collected data to maximize the use of test results.

Quality Assurance

- Radiation data supports WIFI transmission, and image streams can be transmitted in real time.

- Multi-interface exquisite design, M-type positive locking connector, and thermal imager connection are firm. No need to use an additional power cord, equipped with standard Ethernet Power PoE technology. Digital I/O interface sets thermal imager parameters and operations.

Applications

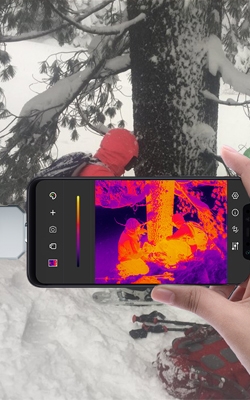

SISCO night vision thermal imaging cameras are essential for wildlife observation and conservation, wilderness survival, night hiking, and industrial and building inspections, providing enhanced visibility and safety in low-light conditions.

Night Hiking

Wildlife Observation

Building Inspections

Wilderness Survival

| Model | SISCO-TIC-FLIRA400 | |

| Detector Data | IR Resolution | 320×240 |

| Visual Resolution | 1280×960 | |

| Focal Plane Array/Spectral Range | <30 mK to<50 mK, lens dependent | |

| IR Camera Focus | One-shot contrast, motorized, manual | |

| Measurement | 0bject Temperatures |

-20℃ to 120℃ (-4℉ to 248℉); 0℃ to 650℃ (32℉ to 1202℉); 300℃ to 1500℃ (572℉ to 2732℉) |

| Accuracy | ±2℃ (±3.6℉) or ±2% of reading | |

| Measurement Analysis | Automatic Hot/Cold Detection | Max./Min. temperature value and position shown within box |

| Scheduled Response | SFTP(image), SMTP(image and/or measurement data/result) | |

| Measurement Frequency | Up to 10 Hz | |

| Measurement Result Read-out | Yes; common protocols include EtherNet/IP, Modbus TCP, MQTT, and REST API | |

| Dynamic Range | 16-bit | |

| Ethernet | Interface | Wired; Wi-Fi* |

| Connector Types | M12 8-pin X-coded, female; RP-SMA, female | |

| Ethernet Type & Standard | 1000 Mbps, IEEE 802.3 | |

| Ethernet Power | Power over Ethernet, PoE IEEE 802.3af class 3 | |

| Ethernet Protocols | lnclude EtherNet/IP, Modbus TCP, and MOTT | |

| Digital Input/Output | Connector Type | M12Male 12-pin A-coded (shared with ext.power) |

| Digital Input | 2×opto-isolated, Vin (low)=0-1.5 V,Vin (high)= 3-25V | |

| Digital Output | 3×opto-isolated,0-48 V DC, max.350 mA(derated to 200 mA at60℃).Solid-state opto relay, 1×dedicated as fault output(NC) | |

| Power System | Connector Type | M12 Male 12-pin A-coded (shared with Digital I/O) |

| Power Consumption | 7.5W at 24V DC typical; 7.8W at 48V DC typical; 8.1W at 48V PoE typical | |

| Packaging | Dimensions | 123mm×77mm×77mm |

| Weight | 0.82kg | |

Packaging List

- Plastic Box

- Instruction Manual

- Host

Q1: What is infrared thermometer?

A1: Infrared thermometer is a temperature measuring instrument based on the principle of infrared rays. This kind of temperature measuring instrument can measure the temperature by the length of infrared rays. Infrared thermometer is a kind of measuring instrument, which can realize short-distance measurement and long-distance measurement, and is a kind of temperature-measuring instrument that can be used in various environments.

Q2: How does infrared thermometer work?

A2: Infrared radiation is the most widespread electromagnetic wave radiation in nature. Objects with a temperature above absolute zero will radiate infrared rays due to their own molecular motion. After the power signal radiated by the object is converted into an electrical signal by the infrared detector, the output signal of the imaging device can completely simulate the spatial distribution of the surface temperature of the scanned object one by one. After being processed by the electronic system, it is transmitted to the display screen and obtained the thermal image corresponding to the heat distribution on the surface of the object.

Q3: What is infrared thermometer used for?

A3: Today, infrared thermal imaging systems have been widely used in fields such as electric power, fire protection, petrochemical and medical treatment. Infrared thermal imaging cameras are playing a pivotal role in the development of the world economy.

Tips: Factors Affecting Thermal Imager Camera Detection

A thermal imager camera is a device that generates thermal images by capturing infrared radiation from the surface of an object. Its detection results may be affected by many factors. Changes in ambient temperature will affect the temperature of the object, thereby affecting the measurement results of the thermal imager camera. Therefore, when taking measurements, it is necessary to keep the ambient temperature stable. The distance between the thermal imager camera and the object being measured will affect the measurement results. When the distance increases, the intensity of the infrared radiation will weaken, resulting in a low measurement result. Therefore, when taking measurements, it is necessary to maintain an appropriate distance and correct the measurement results according to the change in distance. The skill level of the operator is also one of the important factors affecting the measurement results of the thermal imager camera. Skilled operators can more accurately adjust the equipment parameters, select the appropriate measurement position and angle, and obtain more accurate measurement results. Therefore, when using a thermal imager camera, operators need to be professionally trained to improve their skill level.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.