Come with an industrial touch screen, differential calorimeter that can test melting and thermal enthalpy, and thermal stability by computer analysis. The differential scanning calorimetry instrument automatically switches to control the gas nitrogen and oxygen.

Industrial touch screen easy to operate

-

Industrial-grade 8-inch touch screen, the perfect combination of the instrument face frame and touch screen.

- The sensor is tightly integrated with the furnace body, making the baseline more stable, and sensitivity and resolution greatly improved.

- USB communication interface, strong versatility, reliable and uninterrupted communication, and supports self-recovery connection function.

Convenient software control

-

Digital flow meter, more precise airflow control.

- Automatically switch between two-way atmosphere flow, fast switching speed, and short stabilization time. At the same time, add one protective gas input.

- The software is simple and easy to operate.

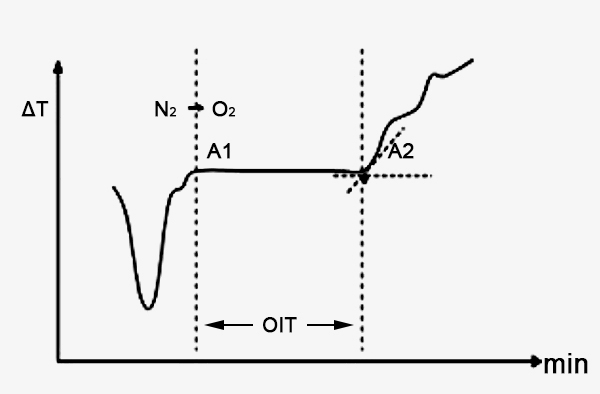

Oxidation Induction Period Curve

Application

As a powerful thermal analysis machine, the differential scanning calorimeter measures the relationship between temperature heat flow and thermal transition inside materials. It is suitable for material research and development, performance testing, and quality control, and plays an important role in many fields such as materials science, chemistry, pharmacy, food science, environment and energy, geology, and mining. Through DSC analysis, important information about the thermal properties of materials can be obtained, providing strong support for scientific research, industrial production, quality control, etc.

Food

Polymer

Chemical Material

Medicine

| Model | SISCO-HM-Q8 | SISCO-HM-C1 | SISCO-HM-C2 | SISCO-HM-C3 |

| Display mode | 15-inch touch screen | 8-inch touch screen | 8-inch touch screen | 8-inch touch screen |

| Temperature range | Room temperature -500℃ | Room temperature -500℃ | Room temperature -500℃ | Room temperature -500℃ |

| Graph analysis | Built-in analysis | Connected to computer analysis | Connected to computer analysis | Connected to computer analysis |

| Function | Full-function type | Melting point only | Specialized for oxidation induction period | Full-function type |

| Temperature resolution | 0.01℃ | |||

| Temperature fluctuation | ±0.1℃ | |||

| Temperature repeatability | ±0.1℃ | |||

| Heating rate | 0.1~100℃/min | |||

| Constant temperature time | <24h suggestion | |||

| Temperature control method | Heating, constant temperature (fully automatic program control) | |||

| DSC range | 0~±600mW | |||

| DSC resolution | 0.01mW | |||

| DSC sensitivity | 0.01mW | |||

| Working power supply | AC 110V 60Hz; AC 220V 50Hz | |||

| Atmosphere control gas | Nitrogen, oxygen (automatic switching of the instrument) | |||

| Gas flow | 0~300mL/min | |||

| Gas pressure | 0.2MPa | |||

| Data interface | Standard USB interface | |||

| Parameter standard | Equipped with standard materials (indium, tin, zinc), users can calibrate the temperature by themselves | |||

Note:

- Full-function type: glass transition temperature, phase transition, melting and thermal enthalpy, thermal stability, oxidation induction period

- Melting point only: melting point

- Oxidation induction period only: oxidation induction period

Q1: What is a differential scanning calorimeter?

A1: Differential scanning calorimeter is a powerful thermal analyzer that possesses a testing technique for selecting an appropriate reference substance and measuring the energy difference between the substance to be measured and the reference substance as a function of temperature. Simply put, a scanning calorimeter studies the physical and chemical changes of a substance by comparing the difference in heat between the sample and the reference substance.

Q2: How does a differential scanning calorimeter work?

A2: A differential scanning calorimeter measures the power difference (for power-compensated models) or temperature difference (for heat-flow models) between a sample and a reference as a function of temperature at a programmed controlled temperature. During the experiment, the temperature of the sample and the reference are kept the same, and then the difference in heat between the two is recorded. The horizontal axis of the digital scanning calorimeter curve is the temperature (or time), and the vertical axis is the difference in heat.

Q3: What does a differential scanning calorimeter do?

A2: The main function of a differential calorimeter is to accurately measure the thermal effects that occur during the heating or cooling of a substance, thus revealing a wide range of thermal properties and phase transition behaviors.

Tips: How to use a differential scanning calorimeter?

Prepare clean, dry samples and treat them appropriately. Confirm that the instrument has been preheated to a stable state and calibrate the instrument as needed. Set appropriate parameters according to the test purpose. Make sure that the temperature program can cover the thermal transition temperature range of the sample. Select a suitable gas atmosphere based on the properties of the sample. Set up appropriate sample boats, reference materials, etc. as needed. Place the sample boat in the furnace of the differential scanning calorimeter and close the furnace door. Start the test program and the instrument will heat according to the set temperature program. After the test is completed, use the supporting software to process and analyze the test data.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.