Differential scanning calorimetry equipment has optional functions of air cooling, semiconductor cooling, and liquid nitrogen cooling. It is equipped with a digital gas mass flow meter and can be controlled by software. The DSC differential scanning calorimetry can measure oxidation induction/glass transition temperature/enthalpy/crystallization/melting. For example, polymer analysis, catalyst evaluation, drug development, and food ingredient identification.

High Precision Performance

- DSC has a new furnace structure, better analysis and resolution, and baseline stability.

- It uses a digital gas mass flowmeter to accurately control the purge gas flow rate, and the data is directly recorded in the database.

Bidirectionally Control

- The differential scanning calorimetry instrument can be bidirectionally controlled (host control, software control), with a friendly interface, simple operation, and easy to use.

- It has the characteristics of good repeatability and high accuracy and is particularly suitable for accurate measurement of specific heat.

- It is easy to calibrate, has a low melting point, and is fast and reliable.

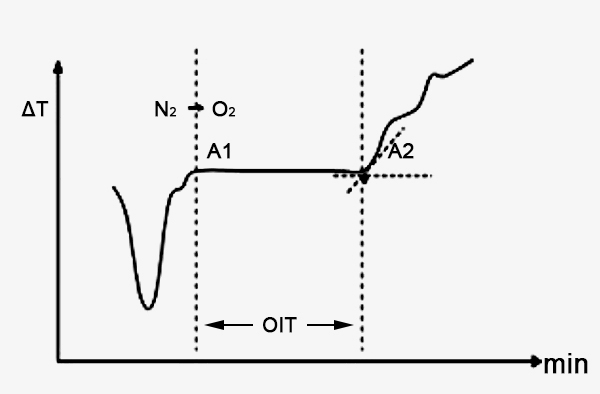

Oxidation Induction Period Curve

Application

As a powerful thermal analysis machine, the differential scanning calorimeter measures the relationship between temperature heat flow and thermal transition inside materials. It is suitable for material research and development, performance testing, and quality control, and plays an important role in many fields such as materials science, chemistry, pharmacy, food science, environment and energy, geology, and mining. Through DSC analysis, important information about the thermal properties of materials can be obtained, providing strong support for scientific research, industrial production, quality control, etc.

Food

Polymer

Chemical Material

Medicine

| Model | SISCO-HNB-DSC100A | SISCO-HNB-DSC300 | SISCO-HNB-DSC300C | SISCO-HNB-DSC300L |

| Temperature range | Room temperature ~ 600°C | -40℃~600℃ | -150℃~600℃ | |

| Cooling method | Air Cooling | Semiconductor Refrigeration | Liquid hydrogen refrigeration | |

| Temperature resolution | 0.01℃ | 0.001℃ | 0.01℃ | |

| Temperature fluctuation | ±0.01℃ | ±0.01℃ | ±0.01℃ | |

| Temperature repeatability | ±0.1℃ | ±0.1℃ | ||

| Heating rate | 0.1~100℃/min | 0.1~80℃/min | ||

| Cooling rate | * | 0.1~20℃/min | * | |

| Constant temperature time | Program setting ≤24h | * | ||

| Curve scanning | Temperature scan | Heating scan, cooling scan | ||

| DSC range | 0~±600mW | 0~±800mW | 0~±600mW | |

| DSC resolution | 0.01uW | 0.001mW | ||

| DSC accuracy | 0.001mW | 0.001mW | ||

| Temperature control method | Heating, constant temperature | Heating, constant temperature, multi-stage testing, cooling scanning | Heating, constant temperature, cooling | |

| Atmosphere control gas | Nitrogen, oxygen | |||

| Gas flow | 0~300mL/min | |||

| Gas pressure | 0.3MPa | 0.2MPa | ||

| Working power supply | AC 220V/50Hz; AC 110V/60Hz | |||

Q1: What is a differential scanning calorimeter?

A1: Differential scanning calorimeter is a powerful thermal analyzer that possesses a testing technique for selecting an appropriate reference substance and measuring the energy difference between the substance to be measured and the reference substance as a function of temperature. Simply put, a scanning calorimeter studies the physical and chemical changes of a substance by comparing the difference in heat between the sample and the reference substance.

Q2: How does a differential scanning calorimeter work?

A2: A differential scanning calorimeter measures the power difference (for power-compensated models) or temperature difference (for heat-flow models) between a sample and a reference as a function of temperature at a programmed controlled temperature. During the experiment, the temperature of the sample and the reference are kept the same, and then the difference in heat between the two is recorded. The horizontal axis of the digital scanning calorimeter curve is the temperature (or time), and the vertical axis is the difference in heat.

Q3: What does a differential scanning calorimeter do?

A2: The main function of a differential calorimeter is to accurately measure the thermal effects that occur during the heating or cooling of a substance, thus revealing a wide range of thermal properties and phase transition behaviors.

Tips: What are the benefits of differential scanning calorimeters?

Differential scanning calorimeters have become indispensable tools in laboratory and industrial quality control due to their high accuracy, wide measurement range, good repeatability, intuitive and easy-to-read data display, ease of operation, wide range of applications, powerful data management features, high sensitivity, fast measurements, and sample versatility.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.