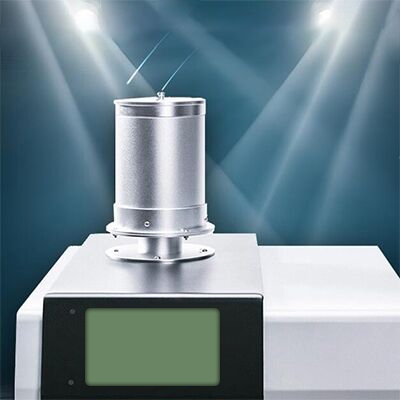

The scanning calorimeter with thermal analysis, temperature range room temp to 1200℃/1500℃, and power supply 110V/220V can be selected. Thermogravimetric analyzers and synchronous thermal analyzers study the thermal and oxidative stability of materials. The test substances include plastics, rubber, coatings, inorganic materials, metal materials, composite materials, catalysts, pharmaceuticals, and food science.

Structural Advantages

- The furnace body heating adopts customized nickel-chromium wire double-row winding to reduce interference and be more resistant to high temperatures.

- The tray sensor is made of alloy wire and has the advantages of high-temperature resistance, oxidation resistance, and corrosion resistance.

- The power supply, circulating heat dissipation par,t and the host are separated to reduce the influence of heat and vibration on the micro-thermal balance.

- The upper cover structure is adopted for easy operation. It is difficult to move the furnace body upward to place the sample, which may cause damage to the sample rod.

- The host adopts the heat insulation heating furnace body to prevent the heat influence on the chassis and the micro-thermal balance. The furnace body of the digital scanning calorimeter can be replaced according to customer requirements.

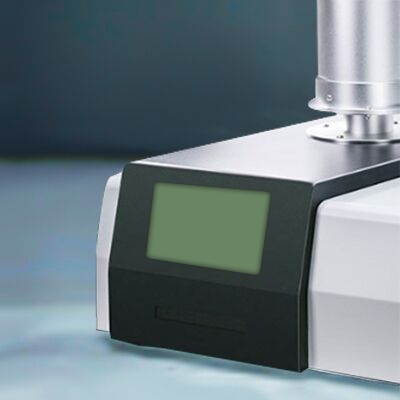

Controller and Software Advantages

- Differential scanning calorimetry machines adopt imported ARM processors, and sampling speed and processing speed are faster.

- Four-way sampling AD collects TG signal and temperature T signal.

- Heating control, using PID algorithm, precise control. It can have multi-stage heating and constant temperature.

- USB bidirectional communication is adopted between software and instrument, which can fully realize remote operation. The instrument parameters can be set and the operation of the instrument can be stopped through computer software.

- DSC calorimeter with 7-inch full-color LCD touch screen, better human-machine interface. TG calibration operations can be realized on the touchscreen.

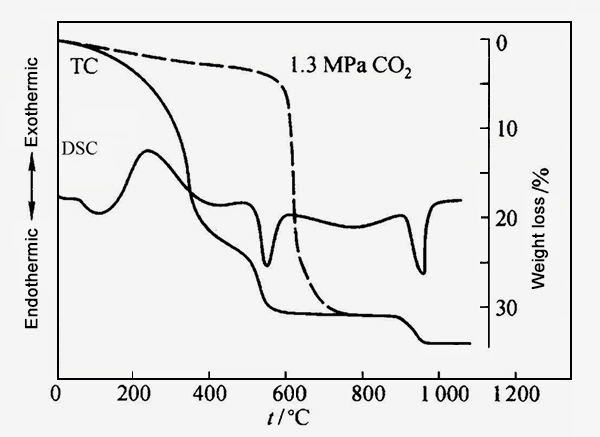

Thermogravimetry and thermal enthalpy change curve of the sample

Application

As a powerful thermal analysis machine, the differential scanning calorimeter measures the relationship between temperature heat flow and thermal transition inside materials. It is suitable for material research and development, performance testing, and quality control, and plays an important role in many fields such as materials science, chemistry, pharmacy, food science, environment and energy, geology, and mining. Through DSC analysis, important information about the thermal properties of materials can be obtained, providing strong support for scientific research, industrial production, quality control, etc.

Food

Polymer

Chemical Material

Medicine

| Model | SISCO-HNB-TGA101 | SISCO-HNB-TGA103 | SISCO-HNB-STA200 | SISCO-HNB-STA300 |

| Type | Thermogravimetric Analyzer | Simultaneous Thermal Analyzer | ||

| Temperature range | Room temperature~1200℃ | Room temperature~1500℃ | Room temperature~1200℃ | Room temperature~1550℃ |

| Temperature resolution | 0.01℃ | |||

| Temperature fluctuation | ±0.1℃ | |||

| Heating rate | 0.1℃~100℃/min | |||

| DSC range | * | 0~±1500mW | ||

| DSC accuracy | * | 0.01mW | ||

| Temp control method | PID algorithm control, heating, constant temperature, cooling, multi-stage heating and cooling program setting, up to 6 stages can be set | |||

| Constant temp time | 0~300min, arbitrarily set | |||

| Balance measuring range | 0.01mg~3g (can be expanded to 50g upon customization) | |||

| Weighing system accuracy | 0.01mg | |||

| Cooling time | ≤15min | |||

| Program control | Realize multi-stage temperature rise control; the program can be set to at least 5 stages | |||

| Atmosphere device | Built-in gas flow meter, including two-way gas switching and flow control atmosphere: inert, oxidizing, reducing, static, dynamic | |||

| Software | Intelligent software can automatically record TG and DTG curves, process data, and print experimental reports | |||

| Data interface | Standard USB interface, dedicated software (software is updated for free from time to time) | |||

| Display mode | 24-bit color, 7-inch LCD touchscreen display | |||

| Power | AC 220V 50Hz; AC 110V 60Hz | |||

Q1: What is a differential scanning calorimeter?

A1: Differential scanning calorimeter is a powerful thermal analyzer that possesses a testing technique for selecting an appropriate reference substance and measuring the energy difference between the substance to be measured and the reference substance as a function of temperature. Simply put, a scanning calorimeter studies the physical and chemical changes of a substance by comparing the difference in heat between the sample and the reference substance.

Q2: How does a differential scanning calorimeter work?

A2: A differential scanning calorimeter measures the power difference (for power-compensated models) or temperature difference (for heat-flow models) between a sample and a reference as a function of temperature at a programmed controlled temperature. During the experiment, the temperature of the sample and the reference are kept the same, and then the difference in heat between the two is recorded. The horizontal axis of the digital scanning calorimeter curve is the temperature (or time), and the vertical axis is the difference in heat.

Q3: What does a differential scanning calorimeter do?

A2: The main function of a differential calorimeter is to accurately measure the thermal effects that occur during the heating or cooling of a substance, thus revealing a wide range of thermal properties and phase transition behaviors.

Tips: What is the differential scanning calorimeter commonly used to measure?

- A differential scanning calorimeter is commonly used to measure the heat flow associated with phase transitions in materials as a function of temperature.

- Melting Points: Determining the temperature at which a solid turns into a liquid.

- Crystallization: Identifying the temperature at which a substance crystallizes.

- Glass Transition Temperature (Tg): The temperature at which an amorphous polymer transitions from a hard, glassy state to a more rubbery, flexible state.

- Heat of Fusion: The amount of heat required to melt a substance.

- Heat of Reaction: The heat change associated with chemical reactions, such as curing or decomposition.

- Oxidative Stability: Measuring the resistance of materials to oxidation.

- The scanning calorimeter is widely used in materials science, chemistry, pharmaceuticals, and polymers to study material properties and behaviors under controlled temperature conditions.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.