The digital caliper meter allows data to be read more clearly, zeroed at any position, and can be quickly switched between metric and imperial systems, which can meet a variety of usage needs and have multiple uses.

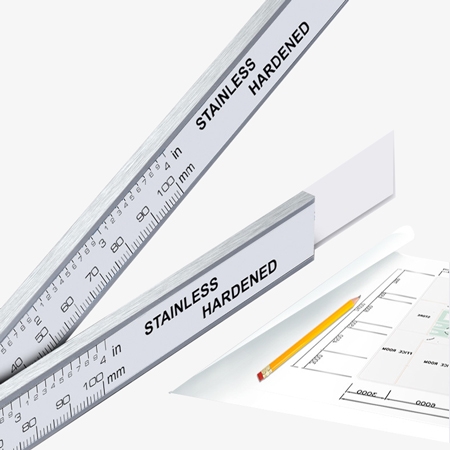

High Precision Measurement

- The measuring jaws of the digital vernier caliper are finely ground and high-temperature quenched and forged. The upper and lower measuring jaws fit tightly, the hand-ground measuring surface is flat, and the fine assembly has a small shaking gap, stronger wear resistance, and more accurate measurement.

- The LCD high-definition digital display screen can be reset at any position to meet the needs of fast switching between metric and imperial systems.

- The resolution is 0.01mm and the error range is ≤0.03mm.

High Quality Guarantee

- The scale is delicate and clear, and the stainless steel ruler body is made of 4CR13 material, which is sturdy and durable.

- The tail of the caliper makes the measuring rod perpendicular to the surface of the object being measured, which makes the measurement more accurate.

- The roller design allows the use of a thumb for convenient measurement.

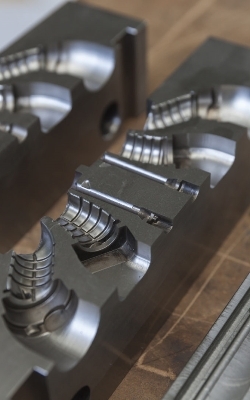

Applications

Vernier calipers are a precision measuring tool widely used in many fields. In the field of industrial manufacturing, vernier calipers are an indispensable measuring tool. It can be used to measure the size of parts to ensure that the quality of the product meets the requirements. In the field of automobile maintenance, vernier calipers are used to measure whether the size of automobile parts meets the standard specifications. By regularly measuring the size changes of key parts, the wear and tear of the parts can be determined and repaired or replaced in time. When installing some precision parts, vernier calipers are used to ensure the accuracy of the installation position and size. In the field of scientific research, scientists often need to measure the size of tiny objects.

Mobile Manufacturing

Mold Manufacturing

Scientific Research

Machinery Manufacturing

| Model | SISCO-DVC150 | SISCO-DVC200 | SISCO-DVC300 |

| Resolution | 0.01mm | ||

| Specifications | 150mm | 200mm | 300mm |

| Error | ±0.03mm | ||

| Material | Stainless Steel | ||

| Scale Process | Magnetic Film | ||

| Battery | LR44 | ||

| Product Packaging | Sponge Plastic Box | ||

| Weight | 0.3kg | 0.35kg | 0.6kg |

Structure Diagram

Packing List

- Instruction Manual

- Desiccant

- Digital Caliper

- Battery

Q1: What is a vernier caliper?

A1: Vernier caliper is a measuring tool for measuring length, inner and outer diameters, and depth. The vernier caliper is composed of two parts, the main ruler and the sliding vernier attached to the main ruler. The depth rod is connected to the vernier to measure the depth of the groove and cylinder.

Q2: What are vernier calipers used for?

A2: As a commonly used measuring tool, sisco vernier calipers can be specifically applied in the following four aspects:

- Measure the width

- Measuring the outer diameter

- Measuring the inner diameter

- Measure the depth

Q3: How does a vernier caliper work?

A3: Mechanical vernier caliper is a commonly used instrument for measuring length in the industry. It consists of a ruler body and a vernier that can slide on the caliper body. Viewed from the back, the cursor is a whole. There is a spring piece between the vernier and the caliper body, and the spring force of the spring piece is used to make the vernier and the caliper body close. There is a fastening screw on the upper part of the vernier, which can fix the vernier at any position on the body of the caliper.

Tips: Daily Maintenance of Vernier Calipers

Vernier calipers are a precision measuring tool, and daily maintenance is essential to maintain their accuracy and extend their service life. Before using a vernier caliper, you need to check whether the surface of the ruler is smooth and scratch-free, whether it is evenly coated with anti-rust oil, etc., to ensure that the surface of the vernier caliper is smooth and works properly. During the use of the vernier caliper, some dust and oil will accumulate, and this dirt will affect the accuracy of the vernier caliper. Therefore, it is very necessary to clean the vernier caliper regularly. When cleaning, you can use a soft cloth or cotton swab to dip a small amount of alcohol or detergent and gently wipe the surface and inside of the vernier caliper. Be careful not to use too wet ca cloth or cotton swab to prevent liquid from penetrating into the inside of the vernier caliper and affecting its accuracy.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.