The digital vacuum pressure gauge has an advanced sensor design with a self-heated thermistor bridge and automatic temperature compensation. The vacuum gauge can automatically compensate for varying temperature conditions, with no manual adjustments necessary. It can work continuously for 30 hours with a 9V alkaline battery, and has low battery indicator and low battery automatic shutdown function.

Comes with a tee and a hook

- The digital vacuum pressure gauge with a convenient design, easy to carry.

- The digital vacuum gauge comes with an integrated three-way valve, allowing you to switch between different pipes or systems for measuring vacuum pressure.

- The digital vacuum gauge for HVAC is equipped with a robust steel hook, providing a secure and reliable method for hanging the gauge during use.

5-digit LCD display

- The digital vacuum gauge is equipped with a high-contrast five-digit LCD display, providing clear and precise readings of the vacuum pressure.

- The large, easy-to-read digits ensure that the measurements can be quickly and accurately read, even in low-light conditions or from a distance.

- The five-digit display allows for highly precise readings, offering detailed measurement data that is crucial for applications requiring exact vacuum levels.

Applications

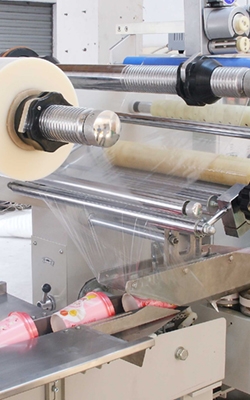

SISCO vacuum gauges are used to measure and monitor pressure in vacuum systems and are essential for maintaining accurate vacuum conditions. It is used in the automotive industry, HVAC, industrial, medical device manufacturing and sterilization, food packaging for extended shelf life, pharmaceutical production, aerospace for high altitude simulation, and the chemical and petroleum industries for processes such as distillation and purification.

HVAC

Industry

Food Packaging

Automotive

| Model | SISCO-VG-200 |

| Sensor Type | Self-heating thermistor bridge with integral temperature compensation from 0-50°C |

| Operating Pressure Range | Atmospheric pressure to 0 micron. Maximum working pressure is 400 psiG |

| Burst Pressure | 3000 psiG |

| Operating Range | Atmospheric pressure to 0 micron |

| Accuracy | ±10% |

| Measurement Unit | microns, Torr, in/Hg, mBar |

| Display | Continuous digital display on 5-digit LCD display |

| Operating Temperature Range | 0-50°C |

| Power Supply | 1*9V alkaline battery (not included) |

| Battery Life | Continuous use for 30 hours |

| Auto Shutoff | After 10 minutes |

| Interfaces | Standard 1/4" internal thread SAE refrigerant hose type with core press |

| Dimensions | 68*40*124mm |

| Weight | 153g |

Q1: What is a vacuum gauge?

A1: A vacuum gauge is an instrument used to measure the pressure in a vacuum system, indicating how much air or gas is present within a closed environment. These gauges are essential in applications where precise control of pressure is required.

Q2: How does a vacuum gauge work?

A2: A vacuum gauge works by measuring the pressure exerted by the gas or air molecules within a vacuum system. Different types of vacuum gauges (such as mechanical, thermal conductivity, and ionization gauges) use various principles to detect and measure this pressure.

Q3: Can I use a vacuum gauge with any type of gas?

A3: Not all vacuum gauges are compatible with all types of gases. Some gauges are sensitive to specific gases, which can affect their accuracy and performance. Always check the manufacturer’s specifications for gas compatibility.

Tips: How is a Digital Vacuum Gauge used in HVAC systems?

A Digital Vacuum Gauge is an essential tool in HVAC (Heating, Ventilation, and Air Conditioning) systems for ensuring proper evacuation and vacuum levels. Here’s how it is used:

- System Evacuation: Before charging an HVAC system with refrigerant, it is crucial to evacuate air and moisture. The digital vacuum gauge measures the vacuum level to ensure the system is properly evacuated.

- Accurate Measurement: The digital display provides precise readings of the vacuum level, helping technicians determine when the desired vacuum level is achieved, typically measured in microns.

- Leak Detection: By monitoring the vacuum level, technicians can detect leaks. If the vacuum level rises after the evacuation process, it indicates a potential leak in the system.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.