Precision vernier caliper is easy to operate and can quickly detect high-precision and large-scale workpieces such as inner diameter, outer diameter, groove width, distance between two holes, depth, etc., and parts that cannot be measured by other instruments can also be detected.

High Precision Measurement

- The digital vernier caliper doesn’t need to adjust the magnification, has four ranges to choose from, is easy to operate, and provides a full range of measurement solutions.

- The caliper ruler is equipped with an LED light column and high-brightness OLED screen display, English menu operation, rich display, and intuitive operation.

- The vernier caliper tools are equipped with a network communication function, carrying an I/O port, can respond to input devices such as photoelectric switches, proximity switches, foot switches, etc., and can control various output devices such as solenoid valves, alarms, motors, etc.

Quality Guarantee

- The optional measuring head is fully ground, with a smooth and delicate surface, quenched and hardened, and durable.

- The software comes with grouping and peak measurement functions and supports expanded communication.

- 100 data can be manually stored, using cyclic rolling storage.

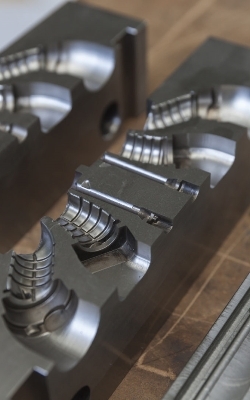

Applications

Vernier calipers are a precision measuring tool widely used in many fields. In the field of industrial manufacturing, vernier calipers are an indispensable measuring tool. It can be used to measure the size of parts to ensure that the quality of the product meets the requirements. In the field of automobile maintenance, vernier calipers are used to measure whether the size of automobile parts meets the standard specifications. By regularly measuring the size changes of key parts, the wear and tear of the parts can be determined and repaired or replaced in time. When installing some precision parts, vernier calipers are used to ensure the accuracy of the installation position and size. In the field of scientific research, scientists often need to measure the size of tiny objects.

Mobile Manufacturing

Mold Manufacturing

Scientific Research

Machinery Manufacturing

| Model | SISCO-VC-AEC3001 | |

| Measuring range | ±5μm, ±10μm, ±25μm, ±50μm | |

| Digital Display Resolution | 0.1μm, 0.2μm, 0.5μm, 1.0μm | |

| Total Error of Indication | 0.2μm, 0.4μm, 1.0μm, 2.0μm | |

| lndication Variability | 0.1μm, 0.2μm, 0.5μm, 1.0μm | |

| Stability (Every 4 Hours) | 0.2, 0.4, 1.0, 2.0 | |

| Response Times | 0.8s | |

| Number of Channels | 1 | |

| Communication Interface | RS232, RS485 | |

| USB Interface | Customizable | |

| Power Supply | AC 185~265V 50Hz/60Hz | |

| Dimensions | 49cm×17cm×38.5cm | |

| Weight | Host | 5kg |

| Handle Type Gas Outside Head | 1kg | |

| Base Type Gas Inside Head | 2kg | |

| Base Type Gas Outside Probe | 2kg | |

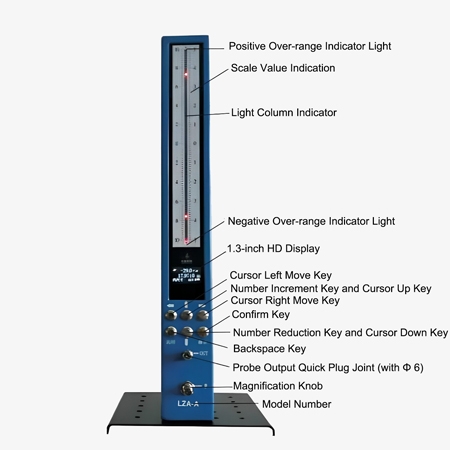

Structure diagram

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.

Q1: What is a vernier caliper?

A1: Vernier caliper is a measuring tool for measuring length, inner and outer diameters, and depth. The vernier caliper is composed of two parts, the main ruler and the sliding vernier attached to the main ruler. The depth rod is connected to the vernier to measure the depth of the groove and cylinder.

Q2: What are vernier calipers used for?

A2: As a commonly used measuring tool, sisco vernier calipers can be specifically applied in the following four aspects:

- Measure the width

- Measuring the outer diameter

- Measuring the inner diameter

- Measure the depth

Q3: How does a vernier caliper work?

A3: Mechanical vernier caliper is a commonly used instrument for measuring length in the industry. It consists of a ruler body and a vernier that can slide on the caliper body. Viewed from the back, the cursor is a whole. There is a spring piece between the vernier and the caliper body, and the spring force of the spring piece is used to make the vernier and the caliper body close. There is a fastening screw on the upper part of the vernier, which can fix the vernier at any position on the body of the caliper.

Tips: How to Calibrate a Vernier Caliper?

Calibrating a vernier caliper usually requires the use of a standard part, such as a calibration block or calibration rod, whose dimensions are precisely known. Here are the general steps.

- Preparation. The calibration needs to be done on a flat and smooth platform on which the vernier caliper can be placed. Prepare some calibration blocks or standard gauge blocks of known size to verify the measurement accuracy of the vernier caliper. In addition, cleaning tools such as dust-free paper or cloth, and lubricants or cleaning agents that may be needed are also required.

- Cleaning the vernier caliper. Use dust-free paper or cloth to gently wipe the scale lines and scale surface of the vernier caliper, making sure the surface is clean and dust-free.

- Adjust the zero position of the vernier caliper. Place the vernier caliper on the platform, make sure its scale lines are aligned with the edge of the platform, and then gently push the measuring feet of the vernier caliper to merge them together. Align the zero mark of the vernier caliper with the zero mark of the main scale by rotating the scale roller or moving the vernier.

- Calibrate the vernier. Move the vernier to the position of the first mark on the main scale and use the calibration needle to adjust the vernier position until the length read on the main scale is consistent with the length read on the vernier. If it is not aligned, use the screw adjustment nut on the calibration needle to make fine adjustments.

Calibration test. Use the vernier caliper to measure objects of different lengths several times to ensure that its accuracy meets the predetermined standard.