SISCO LCD display automatic melting point apparatus can measure one or three samples at the same time. The instrument can automatically calculate the average value of initial melting and final melting. It is your ideal melting point measuring instrument.

Automation and Convenience

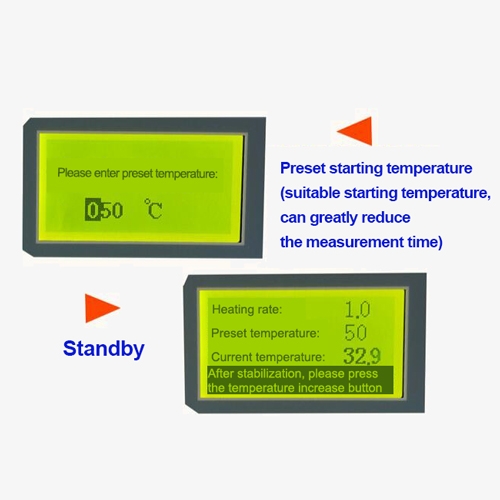

- Equipped with an LCD digital display.

- Fully automatic recording of melting range, initial melting, and final melting. Requires no human supervision.

- Enables quick setting of the "starting temperature" with eight selectable levels of linear heating rate for automatic control.

Quick Detection with High Efficiency Data Transmission

- Comes with an RS232 interface for data transmission to a PC, displaying the melting curve. (only for model MPA-1B)

- Automatic melting point instrument can measure 1 or 3 samples simultaneously with photoelectric detection, improving measurement efficiency.

Applications

SISCO melting point machine uses capillaries, as specified by pharmacopeia, as sample tubes and liquid heat transfer methods. It is widely applicable in industries such as pharmaceuticals, chemical reagents, fragrances, and dyes, for both production and research purposes. This instrument is ideal for measuring the melting point of organic crystalline substances, ensuring high accuracy and reliability in various scientific and industrial applications.

Chemical Reagents

Fragrances

Dyes

Pharmaceuticals

| Model | SISCO-MPA-1A | SISCO-MPA-1B | SISCO-MPA-2 | SISCO-MPA-2A |

| Melting Point Measurement Range | Room temperature to 300°C | |||

| Linear Heating Rate | 0.2, 0.5, 1, 1.5, 2, 3, 4, 5 (°C/min) | |||

| Measurement Repeatability | ±0.5°C (<200°C); ±0.8°C (200°C-300°C) | |||

| Minimum Reading Value | 0.1°C | |||

| Interface | / | Equipped with RS232 interface to transmit data and display curves | / | |

| Processing Power | 1 piece/set (1 sample can be tested at the same time) | 3 pieces/set (3 samples can be tested at the same time) | ||

| Size | 360x310x170mm | 398x280x170mm | ||

| Weight | 10kg | 11kg | ||

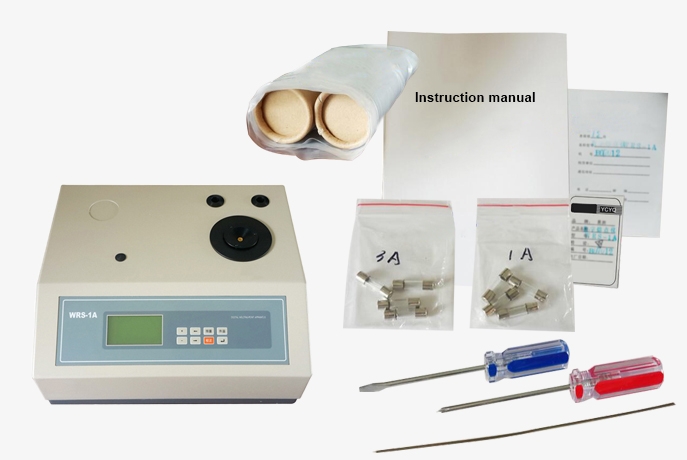

Packing List

- 1 x Melting point apparatus

- 1 x Cleaning rod

- 8 x Fuse

- 2 x Capillary box

- 1 x Screwdriver

- 1 x Certificate of qualification

- 1 x User manual

Q1: What materials can be tested with a automatic melting point apparatus?

A1: A melting point apparatus can test a wide range of materials, particularly organic and inorganic crystalline substances. Common materials include pharmaceutical compounds, chemicals, polymers, fats, and waxes. It is frequently used to assess the purity and identify substances like drugs, chemical reagents, dyes, and flavorings. Additionally, the apparatus is valuable for studying materials that have defined crystalline structures and exhibit phase transitions, making it useful in both research and industrial applications for quality control and material characterization.

Q2: How does impurity affect the melting point?

A2: Impurities in a substance typically lower its melting point and broaden the melting point range. This happens because impurities disrupt the orderly crystal lattice of a pure substance, weakening the bonds between molecules and causing the substance to melt at a lower temperature. As a result, the transition from solid to liquid occurs over a wider temperature range, rather than at a sharp, specific point. In laboratory analysis, this effect is used to assess the purity of a substance: the purer the substance, the sharper and higher its melting point will be.

Q3: What are the typical sources of error in melting point determination?

A3: Typical sources of error in melting point determination include improper calibration of the melting point apparatus, inaccurate sample preparation, and heating the sample too quickly. A poorly calibrated thermometer can result in incorrect temperature readings, while impurities or uneven packing in the sample can cause inaccurate melting point results. Additionally, if the heating rate is too rapid, the sample may not uniformly reach the melting point, leading to a falsely elevated or broad melting point range. Environmental factors, such as air drafts or inconsistent heating, can also contribute to errors in the measurement.

Tips: How does a melting point instrument work?

A melting point apparatus works by heating a small sample of a solid substance, typically placed in a thin capillary tube, while simultaneously measuring the temperature. As the temperature increases, the apparatus closely monitors the sample to detect the precise moment when the solid begins to liquefy and the point at which it completely melts. Advanced models use digital sensors and video recording to capture this transition, ensuring accurate readings. The melting point is recorded as the temperature at which the phase change from solid to liquid occurs, providing important data for identifying and assessing the purity of the substance.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.