The low pressure digital pressure gauge is a highly accurate and compact diaphragm pressure gauge for measuring water pressure, hydraulic pressure, oil pressure and air pressure. The digital absolute pressure gauge has overpressure protection to withstand pressures beyond their maximum rating without damage, ensuring durability and safety.

5 measurement units which is easy to switch

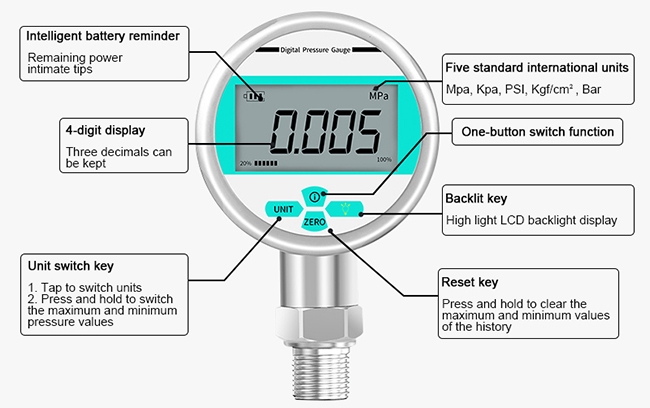

- The digital pressure gauge with a clear, easy-to-read dial that shows 5 pressure readings in psi, kPa, MPa, bar and kfg/cm².

- Increment Markings: The electronic pressure gauge provides precise increment markings for accurate readings.

Powered by 2 AAA batteries, easy to replace

- No external leads and power supply required.

- 4-digit display, can retain 3 decimal places, more accurate measurement.

- Long press to clear the history, maximum and minimum values recorded.

Note: When the LCD digital display is dim or no display, the battery should be replaced in time.

Dimension

Applications

SISCO digital pressure gauges are widely used for various gas or liquid pressure measurements in industries, laboratories, scientific research, HVAC systems, water treatment, etc. The electronic pressure gauges are used to monitor and accurately measure the pressure of liquids and gases in real time. They provide high-precision readings, are easy to read, and can integrate data logging and remote monitoring functions.

HVAC Systems

Laboratory

Water Treatment

Industry

| Model | SISCO-DPS-YB80-100kP |

| Measuring Range | 0-1 bar/ 0-14.5 psi/ 0-100 kPa |

| Accuracy | ±0.2% |

| Thread | M20*1.5 |

| Pressure Type | Gauge pressure, absolute pressure, sealed gauge pressure |

| Measurement Medium | Water, air, hydraulic, oil |

| Dial Size | 80mm |

| Overload Capacity | <40MPa,150%;>40MPa,120% |

| Long-term Stability | 0.25% FS/Y |

| Sampling Frequency | 3 times/s |

| Display Screen | LCD display |

| Supply Voltage | 3V (two AAA batteries) |

| Material | 304 stainless steel |

| Installation Method | Radial |

| Peak Value Recording | √ |

| One-button Power On/Off | √ |

| Unit Conversion | √ |

| Peak and Valley Value Recording | √ |

| Low Power Prompt | √ |

Detail

Q1: What is a digital pressure gauge?

A1: A digital pressure gauge is an instrument that measures and displays pressure readings electronically using a digital display. It typically offers higher accuracy and ease of use compared to analog pressure gauges.

Q2: How does a digital pressure gauge work?

A2: A digital pressure gauge measures pressure using a sensor that converts pressure into an electrical signal. This signal is amplified, converted from analog to digital, processed by a microprocessor, and then displayed on a digital screen. The result is an accurate, real-time pressure reading.

Q3: What is a pressure gauge used for?

A3: Yes, a digital pressure gauge is generally more accurate than a mechanical pressure gauge, as it offers higher precision, better resolution, and easier readability due to its electronic components and digital display.

Tips: Can a digital pressure gauge be calibrated by the user?

Yes, many digital pressure gauges can be calibrated by the user. User calibration typically involves following the manufacturer's guidelines, which may include steps such as:

- Connecting to a Calibration Standard: Use a known pressure source, such as a calibration pump or a standard pressure gauge, to provide a reference pressure.

- Entering Calibration Mode: Most digital pressure gauges have a calibration mode that can be accessed through specific button presses or menu options.

- Applying Known Pressures: Apply a series of known pressures and adjust the gauge readings to match these known values. This may involve setting zero and span points.

- Saving Calibration Settings: Once the adjustments are made, save the calibration settings according to the manufacturer’s instructions.

- Verifying Accuracy: After calibration, verify the accuracy of the gauge by comparing its readings with the calibration standard at various points within its range.

By following these steps, users can ensure their digital pressure gauges maintain high accuracy.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.