Cheap price digital weighing indicator is easy to use, just screw the sensors on the bridge, platform, cage, or pallet, plug in the plug and adjust the electronics once. This weighing scale indicator includes everything you need to build a high-load scale yourself. Whether vehicle scales, scrap scales, pallet scales, horse scales, or livestock scales.

Digital weighing indicator with a 0.8 inch red LED display

- The bright LED display ensures easy reading of weight data, even in low-light or industrial environments.

- The format provides accurate weight measurements for both small and large loads.

- The 0.8-inch display offers a compact solution, ideal for systems where space is limited.

- The simple, bright display allows for quick and efficient operation, enhancing workflow efficiency.

The weighing scale indicator has a protective anti-collision edge design

- The anti-collision edge design protects the sensor from accidental impacts, prolonging its lifespan in rugged environments.

- The specially designed edge helps absorb shocks from bumps or drops, minimizing the risk of damage to the internal components.

- Improved Safety: The design reduces the risk of physical damage to the indicator, ensuring consistent performance and preventing costly repairs.

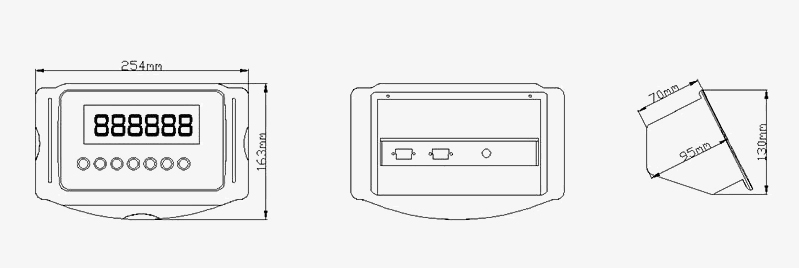

Dimension

Applications

SISCO weighing indicators are widely used for accurate weight measurement in various industries. They are essential in warehouses for inventory management, in supermarkets for weighing products and pricing, in logistics and transportation to prevent overloading, and at ports for weighing containers and ensuring safe cargo handling. These devices enhance efficiency and precision across these applications.

Logistics and Transportation

Warehouse

Wharf

Supermarket

| Model | SISCO-WI-XK315A1X |

| A/D Conversion Principle | Three-integral A/D |

| Display Accuracy | 1/3000~1/30000 |

| A/D Resolution | 100000 |

| A/D Conversion Speed | 40 times/second |

| Sensor Bridge Voltage | DC:5V can connect 4 350Ω sensors or 8 700Ω sensors |

| Display | 6-digit 20mm LED, expandable (×10) display |

| Weighing Method | Gross weight / net weight, manual accumulation / automatic accumulation |

| Division Value | 1/2/5/0.1/0.2/0.5/0.01/0.02/0.05/0.001/0.002/0.005/10/20/50/100/200/500/0.10/0.20/0.50/0.010/0.020/0.050 |

| Serial Communication Interface | Baud rate 1200 2400 4800 9600 optional, RS485 continuous and response mode can be added |

| Printing | RS232 sends serial print output continuously |

| AC Power Supply | AC220V 50/60Hz AC/DC dual-use |

| Using Temperature | –10℃~+40℃ |

| Rechargeable Battery | Built-in 6V/Ah, 6V/2.8AH |

| Storage and Transportation Temperature | ≤-25℃~55℃ |

| Relative Humidity | 10% - 85% non-condensing |

Q1: What is a weighing indicator?

A1: A weighing indicator is a device used in conjunction with weighing scales or load cells to display and process weight measurements. It receives electrical signals from the load cells, converts them into readable weight values, and displays the information on a screen. Depending on the model, weighing indicators can offer additional features like data storage, connectivity for data transfer, and advanced weighing functions such as tare, counting, and totalizing. They are commonly used in various industries, including logistics, warehousing, retail, manufacturing, and more, to ensure accurate weight readings and efficient process management.

Q2: Can weighing indicators be used with different types of scales?

A2: Weighing indicators can be used with a variety of scales, making them versatile tools in numerous industries. They are compatible with different types of scales, such as platform scales for heavy-duty industrial use, bench scales for smaller applications like retail or laboratories, floor scales for bulk weighing in warehouses, and weighbridges for weighing large vehicles in logistics and transportation. Additionally, they can be used with hopper and tank scales in manufacturing and crane scales for suspended loads in construction or shipping. This flexibility allows Weighing Indicators to meet diverse weighing needs across multiple sectors.

Q3: How do weighing indicators communicate with other devices?

A3: Many weighing indicators support communication protocols like RS232, RS485, Ethernet, USB, or wireless options. This allows them to connect to computers, printers, or control systems for data logging or remote monitoring.

Tips: How to maintain a weighing indicator?

Maintaining a Weighing Indicator is essential to ensure its longevity and accuracy. Here are some key tips for proper maintenance:

- Regular Calibration: Schedule routine calibration checks to ensure the indicator provides accurate weight readings. Calibration should be performed according to manufacturer guidelines or when significant discrepancies in measurements are noticed.

- Clean Regularly: Keep the indicator and surrounding area clean. Dust, dirt, or moisture can affect the performance of the display and internal components. Use a soft, dry cloth to clean the device; avoid using harsh chemicals.

- Avoid Electrical Interference: Place the weighing indicator in an area free from electromagnetic interference, as this can affect its accuracy. Keep it away from strong electrical equipment and wiring.

Proper care and regular maintenance will keep the weighing indicator functioning accurately and extend its lifespan.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.