The 3 phase supply phase sequence checker is used to identify open phase lines and detect phase sequence. It is small and convenient, and more convenient to carry.

Easy to Operate

- Anti-electric shock protection alligator clip, insert the test fixture into the metal probe of the probe and tighten it to prevent electric shock.

- High-quality transmission fiber core, good toughness, wear resistance, and faster transmission speed.

- The integrated design of the meter line makes it more convenient to carry when going out for work, and it comes with a wrist strap for more convenience.

Accurate Detection

- High-precision test pen, small error, the tip of the test pen has a threaded design, and can be installed with an alligator clip for testing.

- 5 LEDs and other luminous prompts, the test results are clear at a glance.

Applications

The application scenarios of phase sequence meters are very wide, covering multiple fields from basic power system debugging to complex industrial control systems. It has a wide range of applications in multiple fields. It not only ensures the correct operation of the equipment but also improves the safety and efficiency of the system. With the continuous advancement of technology, the functions of the phase sequence meter will be more diversified in the future, and its application in various fields will become more popular and important.

Equipment Maintenance

Factory Area

Teaching Experience

Electrician Field

| Model | SISCO-PRM-SM852B |

| AC Voltage | 60~600V |

| Test Frequency | 20~400Hz |

| Power Supply | No batteries required |

| Test Cable Length | 100cm |

| Dimensions | 85mm×64mm×23mm |

| Weight | 200g |

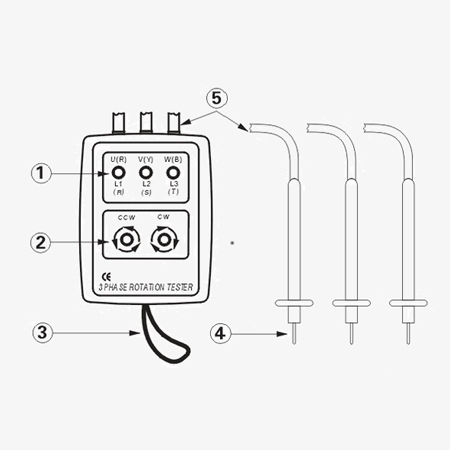

Structure Diagram

Open phase check LED: three orange LEDs, indicating U phase, V phase, and W phase respectively.

Open phase check LED: three orange LEDs, indicating U phase, V phase, and W phase respectively.- Phase sequence check LED: one red LED and one green LED respectively

- Strap: Wear on the wrist to prevent the instrument from slipping out of the hand.

- Test lead: red corresponds to the U (R) phase (L1, R); yellow corresponds to the V (Y) phase (L2, S); green corresponds to the W (B) phase (L3, T).

Packaging List

- Portable Cloth Bag

- Instruction Manual

- Anti-electric Shock Test Clip

- Host, Test Leads, and Test Pen

Q1: What factors can affect the phase rotation meter?

A1: The measurement accuracy and stability of the phase sequence meter may be affected by many factors. First, an unstable power supply or voltage that is too high or too low may cause deviations in the measurement results of the phase sequence meter. Secondly, circuit board aging, component damage, etc. may affect the normal operation of the phase sequence meter. In addition, sensor failure or damage will not be able to correctly detect the phase sequence information of the power supply. Of course, human errors in equipment settings or operating methods can also lead to measurement errors.

Q2: How does a phase rotation meter work?

A2: The working principle of the phase sequence meter is based on the detection and processing of three-phase voltage or current signals. It determines whether the phase sequence is correct by comparing the phase difference between the three-phase voltages. Common phase sequence detection algorithms include those based on zero-sequence detection and those based on positive and negative sequence components. When the phase sequence is correct, these algorithms will output corresponding signals to indicate that the phase sequence is correct; otherwise, they will indicate that the phase sequence is wrong.

Q3: What technical parameters should be paid attention to?

A3: The technical parameters of the phase sequence meter include but are not limited to input voltage range, power supply voltage, meter size, weight, ambient temperature, humidity, etc. These parameters are crucial for evaluating the performance and application scope of the phase sequence meter. In addition, the phase sequence meter must also have a certain insulation strength and anti-interference ability to adapt to different use environments and ensure the safety of operators.

Tips: How to clean a phase rotation meter?

Cleaning the phase sequencer is a simple and important maintenance process that not only ensures the normal operation of the equipment but also prolongs its service life. However, since it involves electrical equipment, special attention must be paid to safety during cleaning to avoid unnecessary risks. Cleaning can be performed by following the steps below.

Step 1: Power off operation. Before cleaning, make sure that the phase sequencer is in a power-off state to prevent electric shock and equipment damage.

Step 2: Appearance inspection. First, wipe the shell of the phase sequencer with a clean soft cloth to remove dust and stains on the surface.

Step 3: Clean the interface. Use dust-free paper or a clean soft cloth to clean each interface part, especially those places that are prone to dust accumulation or poor contact.

Step 4: Clean the interior. If possible, open the shell of the phase sequencer (pay attention to safety risks) and gently remove the dust inside, taking care not to damage the sensitive components inside.

Step 5: Clean the screen. If there is a display screen, use a special screen cleaning fluid and cloth to clean it, and avoid scratching the screen with rough objects.

Step 6: Check the wiring. Check whether all wiring is firm, without looseness or corrosion, and replace it if necessary.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.