Through the portable and user-friendly design, users can quickly obtain a series of parameters that characterize power quality, including voltage deviation, frequency deviation, high-order harmonics and interharmonics, unbalance, sudden rise and fall, flicker and other parameters specified by international standards. It also includes the capture of some transient and surge signals.

Versatile and Reliable Power Quality Monitoring System

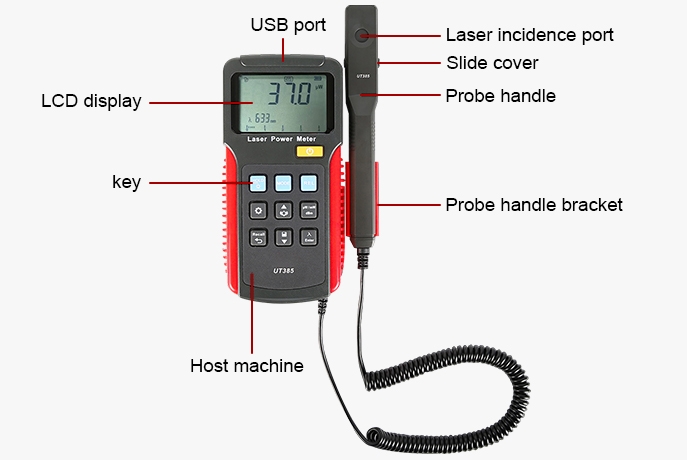

- Precise Laser Sensor: The laser power meter's precise sensor ensures that measurements are highly accurate, making it an essential tool for applications where precision is critical.

- Split Design with Retractable Spring Wire: Enhance flexibility, making it easier to position and handle during use, even in complex setups.

Large Color LCD Display with Auto Range Switching and Bilingual Input

- LCD Screen for Clear Readings: Features an LCD screen that provides clear, easy-to-read measurements, ensuring that data can be easily monitored in any lighting condition.

- Selectable and Customizable Wavelengths: Allowing power meter to be tailored to specific testing needs and increasing its versatility across different laser systems.

Advanced Event Capture, Data Recording, and Customizable Analysis Reporting

- Threshold Alarm Function: Threshold alarm function alerts users when measurements exceed or fall below set limits.

- Low Power Consumption: Designed with low power consumption in mind, the laser power meter ensures extended use on a single battery charge.

- Data Storage Function: Equipped with a data storage function, the laser power meter allows users to save and review measurement data over time, helping to track performance and maintain quality control.

Applications

A laser power meter is an essential tool used in various applications where precise measurement of laser power is critical. It is widely utilized in research and development, manufacturing, and quality control processes to ensure that lasers are operating within specified power levels. In industries such as telecommunications, medical devices, and material processing, a laser power meter helps in calibrating and verifying the performance of laser systems, ensuring they meet safety standards and function optimally. Additionally, it plays a crucial role in scientific experiments and optical testing, where accurate laser power measurements are necessary to achieve reliable and reproducible results.

Laser Equipment Production

Industrial and Mining

Laboratory

Research & Development

| Model | SISCO-PQA-UT385 |

| Specifications | Range |

| Certificates | CE, RoHS |

| Measurement Range | 0uW~39.99mW |

| Measurement Accuracy | 0uW~10uW: ±(5%+0.3); 10uW~39.9mW: ±5% |

| Laser Wavelength Range | 400nm~1100nm |

| Laser Wavelength Preset Options | 520nm, 633nm, 650nm, 780nm |

| LCD Display | 4-digit LCD display |

| Sampling Rate | 0.5s |

| Data Storage | 199 sets |

| Battery Level Indication | √ |

| LCD Backlight | √ |

| Auto Power Off | √ |

| Operating Temperature | 0~40°C |

| Operating Humidity | 80%RH (no condensation) |

| Storage Temperature | -10°C~50°C |

| General Characteristics | |

| Power | 9V battery (6F22) (not including) |

| Display | 57mm x 37mm |

| Net Weight | 319g |

| Product Size | 198mm x 104mm x 35mm |

Details

Packing List

- 1 x Laser power meter

- 1 x USB data cable

- 1 x Warranty card

- 1 x User manual

- 1 x Packing box

Q1: What types of lasers can be measured with a laser power meter?

A1: A laser power meter can measure a wide range of lasers, including continuous-wave (CW) lasers and pulsed lasers, across various wavelengths. These meters are typically designed to handle different laser types, such as diode lasers, solid-state lasers, fiber lasers, and gas lasers, provided they fall within the meter's specified power range and wavelength sensitivity. Whether measuring low-power lasers used in telecommunications or high-power industrial lasers, the appropriate laser power meter can accurately assess the output to ensure optimal performance and safety in different applications.

Q2: How does low power consumption benefit the use of a laser power meter?

A2: Low power consumption in a laser power meter extends the device's operational time, making it more reliable and convenient, especially in fieldwork or extended testing scenarios. By reducing the frequency of battery replacements or recharges, it ensures that the meter is always ready for use, minimizing downtime and enhancing productivity. Additionally, low power consumption contributes to the overall durability of the meter by reducing the strain on its power components, thereby increasing the device's lifespan and making it a more cost-effective tool over time.

Q3: What is the importance of wavelength selection in a laser power meter?

A3: Wavelength selection in a laser power meter is crucial because different lasers operate at specific wavelengths, and accurate measurement depends on the meter's ability to match these wavelengths. A laser power meter with selectable and customizable wavelength settings can accurately measure the power output across various types of lasers, ensuring precise readings. This capability is particularly important in applications where lasers with different wavelengths are used, such as in telecommunications, medical devices, or industrial processes. Without proper wavelength selection, the measurements could be inaccurate, leading to potential errors in laser performance assessment and overall system reliability.

Tips: How does a laser power meter work?

A laser power meter works by using a sensor to detect the energy output of a laser beam. When the laser beam strikes the sensor, the energy is absorbed and converted into an electrical signal. This signal is then processed by the meter's internal circuitry to determine the laser's power level, which is typically displayed on an LCD screen. The sensor is often calibrated to specific wavelengths to ensure accurate measurements, making the laser power meter an essential tool for assessing the performance and safety of laser systems across various applications.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.