The SISCO rolling meter counter is designed according to specific needs and is used as a recorder for length and various mechanical transmissions. It is commonly used for recording the length of materials in industries such as textiles, dyeing, plastic film, artificial leather, and other mass-length applications.

Counting Functionality and Performance Details

- When the second digit of the counter displays "1," the recorded length is 1 meter, and the roller completes three rotations.

- The meter counter features a six-digit display and allows the shaft to rotate in both forward and reverse directions: forward rotation increases the count, while reverse rotation decreases it. The maximum recording range is from 1 to 99999.9.

Additional Functions and Adaptability Features

- Rolling type meter counter includes a reset mechanism. After recording a certain quantity, pressing the reset button will reset all digits to zero, allowing for the next stage of recording.

- The meter counter machine ensures smooth number progression, accurate counting, clear number display, and reliable performance in working environments ranging from -15°C to 55°C.

Applications

SISCO's mechanical meter counter is widely used in various industries such as textiles, dyeing, plastic film, artificial leather, and more, for recording the length of materials. It plays a crucial role in accurately measuring and tracking the length of materials as they are processed or produced, ensuring efficient production control and precise inventory management. With its reliable performance and adaptability, it is ideal for industries that require precise length measurement over large volumes, helping to improve productivity and maintain consistency in manufacturing processes.

Plastic Films

Printing and Dyeing

Leather

Textiles

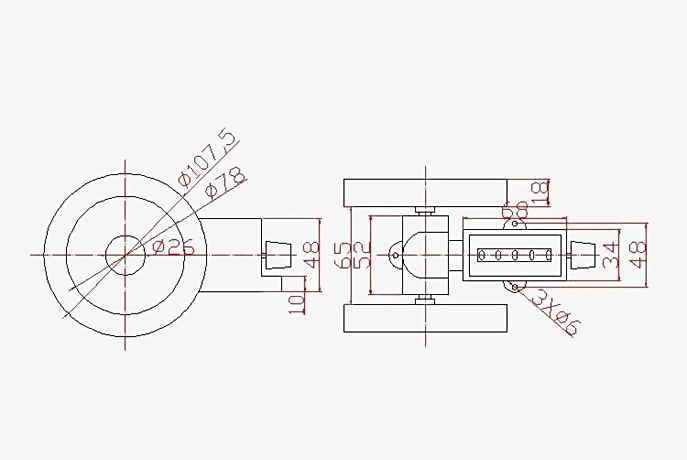

| Model | SISCO-MC-JM316 |

| Counter Range | 0~99999.9 |

| Counter Speed | 200 times/Min |

| Transmission Rate | 1:3 |

| Material | ABS |

| Reset | √ |

| External Dimensions | 175x106x106mm |

| Mounting Dimensions | 98x16mm |

| Wheel Dimensions | 106x18mm |

| Weight | 550g |

Details

Q1: What materials can a roller-type meter counter measure?

A1: A meter counter can measure a wide variety of materials, particularly those that are in the form of continuous rolls or lengths. These materials typically include textiles, such as fabrics and yarns, as well as plastic films, rubber sheets, artificial leather, and cables. It can also be used for measuring other types of flexible materials such as paper, foil, and non-woven fabrics. The meter counter is ideal for industries that require precise measurement of material lengths during production, processing, or packaging, ensuring accuracy and efficiency in material handling and inventory management.

Q2: What are the types of meter counters?

A2: Meter counters come in various types, each designed for specific applications and material handling needs. Common types include mechanical meter counters, which use gears and manual mechanisms to measure length; electronic or digital meter counters, which provide more accurate and precise readings using sensors and digital displays; and rolling meter counters, typically used for materials that are unwound or unrolled, such as fabrics, films, or cables.

There are also specialized meter counters for high-speed applications, like those in manufacturing lines, which can handle faster counting rates and higher precision. Additionally, some models include features like reset functions, adjustable counting speeds, and the ability to measure in both forward and reverse directions, offering flexibility in various industries.

Q3: What should be considered when using a meter counter?

A3: When using a meter counter, several key factors must be considered to ensure accurate and reliable measurements. First, it's important to ensure that the material being measured is properly aligned with the counter’s sensor or mechanism. Misalignment can cause inaccurate readings or even damage to the counter. The type of material being measured also plays a role; materials with varying thickness, flexibility, or surface texture may require adjustments to the counter’s settings, such as tension or speed, to ensure precise measurement. It's also vital to regularly calibrate and maintain the meter counter, as wear and tear over time can affect its performance.

Additionally, operational conditions such as temperature, humidity, and environmental factors should be taken into account. Extreme temperatures or high humidity can influence the performance of both mechanical and electronic meter counters, leading to discrepancies in readings or malfunction. It's also important to consider the counter's capacity, such as its maximum counting speed and range, to ensure it is suitable for the specific application. Overloading the counter or using it beyond its specified limits can lead to errors or damage. Proper training for operators is essential to ensure that the meter counter is used effectively and that any issues are promptly addressed.

Tips: how does a meter counter work?

A meter counter works by tracking the movement of material, typically in the form of a continuous roll or length, as it passes through the counter. The counter is usually equipped with a mechanical or electronic system that measures this movement and converts it into a length reading.

In a mechanical meter counter, a rotating shaft or roller is connected to the moving material, and as the material moves, the shaft or roller rotates. This rotation is then translated into a numerical count, which is displayed on a mechanical dial or a digital display. The counter’s gears and mechanisms are designed to count the number of rotations and calculate the corresponding length, often based on a pre-set ratio that links the number of rotations to the length of material passed.

In an electronic meter counter, sensors detect the movement of the material and send signals to a microprocessor, which processes the information and displays the length on a digital screen. These counters may offer greater accuracy and features such as reset functions, adjustable counting speeds, and higher counting ranges. The working principle is similar in both types, but electronic counters typically offer more flexibility, faster response times, and additional functions such as automatic reset or integration with other machinery.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.