The moisture meter is portable and can be easily carried on-site for rapid testing, making it an ideal instrument for use in the textile industry, trade, scientific research, and quality inspection departments. Its convenient portability and quick measurement capabilities ensure efficient and accurate moisture assessments, supporting critical decision-making processes in various professional settings.

Advanced Functionality and Efficiency Textile Moisture Measurement Device

- Automatic Calibration: Equipped with an automatic power-on calibration function for hassle-free operation.

- Comprehensive Data Management: The moisture device features the ability to store statistics and simultaneously display multiple types of data.

- Efficient and Fast Measurement: The fabric moisture meter offers rapid measurement, providing real-time results that can effectively replace the traditional oven method.

Enhanced Display and Customization Humidity Meter

- High-Definition LCD Screen: High-definition LCD displays digital data, making it easy to read data.

- Precision Adjustment: A deviation correction function is available to handle special cases and ensure accuracy.

- Customizable Measurement Settings: Including a built-in set of common codes, with an additional five sets available for users to customize based on specific needs.

Cutting-Edge Sensor Technology and Enhanced Safety

- Electromagnetic Wave Sensor probe: Adopts electromagnetic sensor technology, with strong penetration ability and high measurement accuracy

- Safety and Alerts: The moisture tester also includes an alarm function with a maximum value hold feature for added safety and reliability.

Applications

SISCO fabric moisture meter is extensively used in industries such as cotton, wool spinning, silk, and hemp products, where rapid and precise measurement of moisture content is crucial. In cotton processing, it ensures the fibers are at the optimal moisture level for quality control and efficiency. In wool spinning and silk production, the meter helps maintain the right moisture balance, preventing issues like shrinkage or fiber damage. Additionally, in hemp processing, accurate moisture measurement is vital to avoid mold growth and ensure product quality. The device is also essential in recycling oil wool strips, where maintaining proper moisture levels is critical to preserving the material's integrity.

Coil

Silk Product

Linen Product

Cotton

| Model | SISCO-MM-HYT106 |

| Display | Multi-parameter LCD digital display |

| Response Time | 1s |

| Measurement Range | 4-90% |

| Resolutions | 0.1 |

| Operation Temperature | -10℃-60℃ |

| Operation Humidity | <85% |

| Accuracy | ±0.5% |

| Power Supply | 4 X 1.5AA battery (not including) |

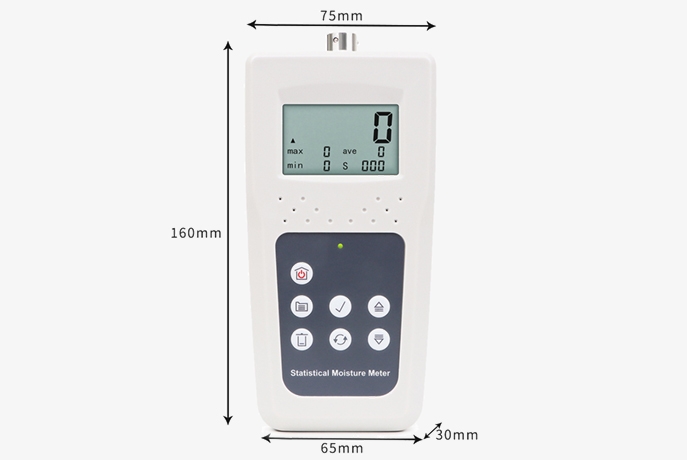

| Dimension | 145mm×70mm×30mm |

| Weight | 120g |

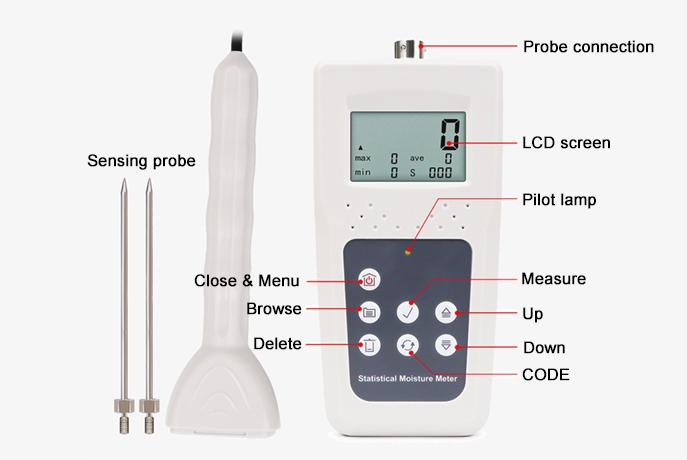

Details

Dimensions (mm)

Packing List

- 1 x Moisture meter

- 1 x User Manual

- 1 x Needle sensor probe

- 1 x Packing box

Q1: What is the difference between a pin and pinless humidity meter?

A1: A pin moisture meter uses two metal probes that are inserted into the material to measure moisture content based on electrical resistance, which gives a precise reading of the moisture level at the exact depth of the pins.

In contrast, a pinless moisture meter employs electromagnetic waves to scan the material's surface without penetration, providing a non-invasive method that measures moisture content over a larger area and just below the surface. While pin meters are ideal for pinpointing specific moisture levels within a material, pinless meters are preferred for assessing moisture content in finished surfaces or when avoiding surface damage is crucial.

Q2: What environmental factors can affect textiles moisture meter readings?

A2: Environmental factors such as ambient humidity, temperature, and static electricity can significantly affect textile moisture meter readings. High humidity can cause moisture in the air to be absorbed by the fabric, leading to higher moisture readings, while low humidity might result in lower readings. Temperature variations can also impact the accuracy, as both the meter and the fabric might respond differently in extreme heat or cold. Additionally, static electricity, often generated in dry environments, can interfere with the meter's sensors, leading to inaccurate readings. Therefore, it's essential to measure moisture content in a controlled environment, where these factors are stabilized to ensure accurate and reliable results.

Q3: How to maintain and store a textile moisture meter?

A3: To maintain and store a pin textile moisture meter properly, clean the pins after each use to remove any textile fibers or debris, and regularly check for any signs of wear or corrosion, replacing the pins if necessary. Ensure the device is calibrated periodically, especially if used frequently or in varying environments, and keep the battery in good condition, replacing it as needed.

Store the moisture meter in a cool, dry place, ideally in its protective case, to avoid exposure to extreme temperatures, humidity, or direct sunlight. Additionally, handle the meter with care to prevent any physical damage, and avoid direct exposure to water or liquids to protect its electronic components.

Tips: Precautions for using fabric moisture meter.

- Moisture is not consistent in the measured object, the moisture contained in different positions of the same measured object will be different, so the measured results will be different.

- The insertion depth of the stylus directly affects the measurement results. ln general, the deeper the insertion, the higher the measured moisture value, so please pay attention to the consistency of the insertion depth of the stylus.

- This textile moisture meter is a high-resistance device, and each part should maintain good insulation. When using andstoring, pay attention to dust and moisture, so as not to affect the measurement results.

- lf the moisture meter is not used for along time, please remove the battery to prevent damage to the instrument caused by battery leakage.

- The probe is strictly prohibited to be directly inserted into the liquid, otherwise the internal liquid will cause short circuit and damage to the internal devices.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.