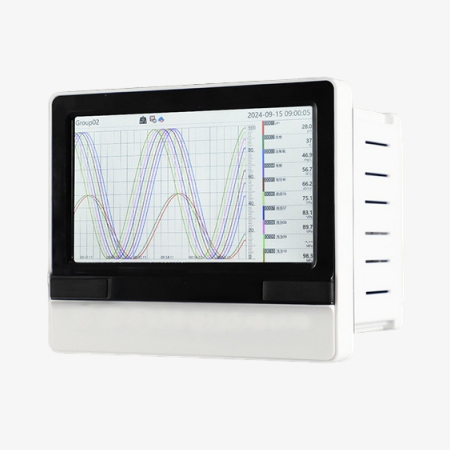

This paperless graphic recorder is equipped with a 7" HD capacitive touch screen, providing a user-friendly interface and clear display. Operators can easily browse trend graphs, real-time data, and historical logs, improving the efficiency of industrial process monitoring.

7-Inch High-Definition Capacitive Touchscreen

- Paperless chart recorder offers selectable 8/16/24/32 channels, allowing users to configure the system based on their data acquisition requirements.

- Paperless data recorder features a 7-inch high-definition capacitive touchscreen, providing a clear, intuitive, and responsive user interface.

- SISCO paperless data logger supports multiple PLCs and inverter drivers, ensuring seamless integration with industrial automation systems.

- Paperless recorder supports USB and SD card data transfer, making it easy to back up and export recorded data for further analysis.

Supports Advanced Script Programming

- Built-in database functionality enables efficient data management, storage, and retrieval.

- Image library support allows users to store and display graphical data for better visualization.

- Paperless recorder supports sampling records and log functionality, ensuring real-time data logging and historical data tracking.

- Paperless chart recorder supports advanced script programming, providing flexibility for customized automation and data processing.

Applications

SISCO paperless recorders are mainly used in various application scenarios such as metallurgy, petroleum, chemical industry, building materials, papermaking, food, pharmacy, colleges and universities, biological research, heat treatment, water treatment, and so on.

Light Industry

Petrochemical

Papermaking

Power Generation

| Model | SISCO-PLR-OHRK800 | |

| Measurement Input | ||

| Input Signal | Analog Input Channel | 8/16/24/36 Channel |

| Current | 0~20mA, 0~10mA, 4~20mA, 0~10mA square root, 4~20mA square root | |

| Voltage | 0~5V1~5V, 0~10V, ±5V, 0~5V square root, 1~5V square root, 0~20 mV, 0~100mV,±20mV, ±100mV | |

| Thermal Resistance | Pt100, Cu50, Cu53, Cu100, BA1, BA2 | |

| Linear Resistance | 0~400Ω | |

| Thermocouple | B, S, K, E, T, J, R, N, F2, Wre3-25, Wre5-26 | |

| DI Switch Input | Low level<1V, 4.5V | |

| Output | ||

| Output Signal | Analog Output | 4~20mA (load resistance ≤380Ω), 0~20mA (load resistance ≤380Ω) |

| 0~10mA (load resistance ≤760Ω), 1~5V (load resistance ≥250KΩ) | ||

| 0~5V (load resistance ≥250KΩ), 0~10V (load resistance ≥500KΩ) | ||

| Alarm Output | Relay normally open contact output, contact capacity 1A/250VAC, 1A/24VDC (resistive load) | |

| Note: When the load exceeds the relay contact capacity, please do not directly carry the load | ||

| Feed Output | DC24V±10%, load current ≤250mA | |

| Communication Interface | ||

| RS485 | RS485 communication interface, baud rate 2400~57600bps can be set, using standard Modbus RTU communication protocol | |

| RS485 communication distance can reach 1 km | ||

| Ethernet | EtherNet communication interface, using Modbus TCP/IP protocol, communication rate 10M/100M adaptive | |

| Wireless | WiFi | 2.4GHz frequency band |

| Comprehensive Parameters | ||

| Measurement Accuracy | 0.2%FS±1d | |

| Sampling Cycle | 1 second | |

| Setting Method | Parameter setting value password lock; setting value is permanently saved after power off | |

| Display Mode | 7-inch 1024*600 capacitive high-definition touch color display | |

| Data Backup | Supports USB flash drive and SD card for data backup and transfer, with a maximum capacity of 32GB, supporting FAT and FAT32 formats | |

| Storage Capacity | Internal Flash memory capacity 8G Byte | |

| Recording Interval | Nine options are available: 1, 2, 4, 6, 15, 30, 60, 120, 240 seconds | |

| Storage length (continuous recording without power failure) | 310 days (32 channels at 1 second interval) - 596523 days (4 channels at 240 seconds interval) | |

| Note: If the instrument has a custom screen function, the storage space will also be occupied by the custom screen. The specific storage length depends on the custom screen project file | ||

| Operating Environment | Ambient Temperature | -10~50℃ |

| Relative Humidity | 10~90%RH (no condensation) | |

| Working Power | AC85~264V (switching power supply), 50/60Hz | |

| Power Consumption | ≤20W | |

| Weight | 2kg | |

Q1: What is a paperless recorder?

A1: A paperless recorder is an instrument that records the collected data/arithmetic data on a time-based axis in the instrument's internal storage system without consuming any common recording facilities, such as paper, pen, and ink. The stored data recorded inside the instrument is displayed on the LCD screen after calculation and simulation. Commonly used display LCD screens are more extensive. On the LCD screen, digital display, bar graph display, curve display, alarm list, etc. can be displayed.

Q2: What is the use of different channel numbers of paperless recorders?

A2: The number of channels of urgent interest means that the scene is necessary to record the next few data on the selection of several channels, for example, if the scene is only a point of temperature, then choose a channel, there are two points of temperature necessary to record the selection of two channels. Usually in order to facilitate future expansion, you can choose a few more channels on the basis of this backup.

Q3: What’s the difference between a circular chart recorder and a paperless recorder?

A3: A circular chart recorder uses pens and paper to log data on a rotating chart—simple but requires manual paper and pen changes. A paperless recorder stores data digitally, supports 8/16/24/32 channels, offers touchscreen display, USB/SD transfer, and remote monitoring. It's more advanced and maintenance-free.

Tips: How do I select the right number of channels (8/16/24/32) for my application?

Choosing the right paperless recorder configuration depends on the number of input signals you need to monitor simultaneously. For basic applications, an 8-channel recorder may be sufficient, while 16, 24, or 32-channel models are ideal for complex industrial processes requiring extensive data logging. If you anticipate future expansion, opting for a higher-channel model ensures scalability. Additionally, consider factors like sampling rate, data storage capacity, and communication interfaces (USB, Ethernet, Modbus) to match your operational requirements.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.