A water pipe leak detector is a device specially used to detect leaks and leaks in pipelines. It uses advanced technical means to monitor pipeline leakage and leakage mainly through sensors and data processing systems. Specifically, the sensor is responsible for collecting key parameter information of the environment around the pipeline, such as temperature, pressure, sound, etc. The data processing system performs analysis and calculation based on the information collected by the sensor to determine whether there is a risk of leakage in the pipeline and issue a timely warning Alarm signal. It can monitor the flow status of liquid or gas in the pipeline system in real-time, and promptly detect hidden leaks in the pipeline system, ensuring the safety of pipeline transportation.

Compared with traditional detection methods, new water leak detectors for underground pipes have the following significant advantages:

- Efficiency. It can complete the inspection of large-area pipeline networks in a short time. It is easy to operate, has fast inspection speed, can quickly obtain inspection results, and can realize real-time monitoring of liquids or gases in the pipeline system, thereby promptly discovering potential leakage risks and ensuring pipeline safety. Transportation security. This is particularly important where leaks need to be discovered and dealt with promptly.

- High accuracy. The running water detector analyzes and calculates the information collected by the sensor to determine whether there is leakage in the pipeline, avoiding errors in human judgment.

- Simple operation. The water leak tester is simple to operate and does not require professional technicians. Anyone can use it with simple training. Non-destructive testing that does not require cutting, disassembly, or destruction of the pipeline protects the integrity of the pipeline and reduces the risk of secondary damage caused by maintenance testing.

- Wide range of applications. There are various types of pipes detectors, which can be applied to different types of pipeline systems, such as oil, natural gas, cement, etc.

Detecting The Leaking Point

Locking The Leaking Area

The "direct listening method" of using a mechanical leaking rod or sensor to contact the pipeline for inspection. The "direct listening method" refers to listening to the sound of water leakage directly from the pipeline. It can take advantage of the good sound transmission performance of the pipeline to directly contact the mechanical leaking rod sensor probe with the pipeline, or connect the vibration sensor probe to the listening rod to contact the pipeline. Attention should be paid to holding it steadily to avoid friction noise. If the pipeline is not exposed to the road, the appropriate valve well should be selected to contact the listening rod.

Accurate Positioning

Choose the appropriate time and place for detection. When detecting leaks, in addition to judging the location of the leak point according to the sound size, the sound quality should also be distinguished, mainly the frequency composition. Simply put, sounds with more high-frequency components feel crisp, and sounds with more low-frequency components feel low. The farther the sound of water leakage on the pipeline spreads, the more high-frequency components are lost, and the lower it sounds. The closer to the leak point, the crisper the sound, so experienced detectors can roughly estimate the distance of the leak point based on the change in frequency.

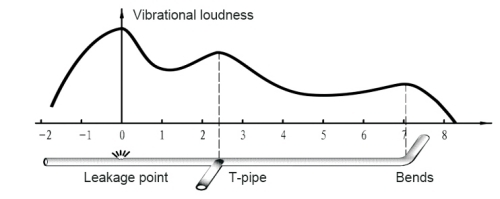

If the pipe has good sound transmission, it is an advantage to use it, but at the same time, if someone uses water nearby, the sound of the faucet will also be heard. When water is busy during the day, there will be continuous sound on the pipe. Whether it can be grasped and analyzed from the accidental interval time is a detection technology. Generally speaking, it is easier to grasp at night when there is little water. The attenuation of the signal on both sides of the joints such as valves and corners can cause mutations. According to the difference in the strength of this mutation on both sides, it can be judged that the leakage should be on the side with high intensity (loud sound). According to the characteristics of different frequencies of sound having different attenuation at the same distance during the transmission (process) of the pipeline, the distance between the leakage point and the measuring point can be judged, that is, the distance with more high-frequency components (sharp sound) is close, and the distance with more low-frequency components (dull sound) is far. Continuously listening to the situation of several wells will know which small section the leakage occurs.

It is necessary to grasp the continuity of the leakage sound. Once a leak occurs, if it has not been repaired or blocked due to long-term siltation, it will continue to leak for a long time. It is different from a tap or a device that releases water at a fixed time and quantity. According to the continuity of the pipeline leakage, it is easy to distinguish whether it is a leak or a release when listening at night (when the cross-water consumption of users is small). When the pressure in the pipe is high, the sound of the leak is also loud, and vice versa. Mastering this feature makes it easy to distinguish between environmental noise and leak noise. In addition, as the position changes, the key to detecting the fixed point lies in "comparison". It is not very meaningful to listen only at one point. Only comparing the relative values of different points is meaningful.

Special attention should also be paid to the vibration caused by the pipeline due to factors such as turns, tees, saddles, and joint bulges, and the resonance of certain points on the pipeline caused by normal water flow or leakage in the pipeline. The sound emitted by this resonance is sometimes stronger than the sound of the actual leaking point, which requires strengthening actual measurement and experience accumulation.

Analysis of Water Leakage Vibration

From the mechanism of vibration caused by pipeline leakage, we can understand its characteristics as a vibration source. First, the pressure water rushes out from the damaged part of the pipeline, excites vibration at the outlet, and generates injection noise. Second, the pressure water impacts the surrounding medium of the pipeline, that is, the surrounding soil layer and the ground surface, causing impact vibration. Third, after the pressure water rushes out of the pipeline, it needs to find the source. It may rush out of the gap nearby, causing water flow disturbance, tumbling flow, and corresponding sound. Due to the complexity and diversity of these mechanisms, especially in real conditions, different pipe materials, different pipe diameters, different forms of broken pipe openings, different injection directions, different water pressures, different buried layers, etc., will affect the conditions for the occurrence of water leakage vibration. Actual detection also proves that water leakage vibration is a complex vibration with continuous but fluctuating vibration. Therefore, the vibration caused by water leakage often has various complex vibration frequencies, ranging from tens of hertz to several thousand hertz. At present, many electronic amplified liquid leak detectors at home and abroad have frequency coverage in this range.

In addition, water pressure will also affect the analysis of water leakage detection. When the water pressure is high, the water will flow out of the nozzle quickly, the impact energy will be large, and the vibration will be large. When the water pressure is too low or the pressure is lost and the flow is slow, the vibration will be weak or even disappear.

When choosing a water pipe leak detector, you should consider the sensitivity of the detector, the applicable pipeline type, environmental adaptability, ease of operation, and whether it has data analysis and storage functions. According to your specific needs and budget, you can choose the relevant test and measurement equipment you like from the SISCO online store.