The leak detector for water is a device specially used to detect water leakage in water supply pipelines and other pressure pipelines. Different types of pipe detectors may use different technologies, which can be roughly divided into two types: using sound wave conduction and signal processing technology to locate the leak point. In this article, SISCO Online Store will introduce a water pipe leak detector using sound wave conduction technology to help you better choose your favorite pipeline leak detector.

Manifestations of Pipeline Leakage

The water supply pipe is a water pipe with a certain water pressure. This is because the water pressure in the water supply pipe is the key factor in ensuring that water can flow from the water source to the water supply point. Water pressure allows water to overcome gravity and friction resistance in the pipe and flow in the pipe network. Without sufficient water pressure, water cannot reach users on higher floors or far away, affecting the continuity and reliability of the water supply.

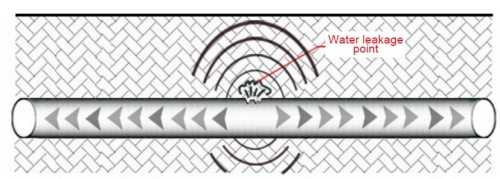

When there is a water leak somewhere, pressurized water will spray outward from the crack of the pipe. The friction between the pressurized water and the crack of the pipe mouth will cause vibration and impact noise. The noise will spread to both sides of the pipe. A fairly strong sound of water leakage can be heard within 20 meters on DN≥100MM metal pipes, 60 meters on DN≤50MM metal pipes, and 2 meters on plastic pipes (PE, PPR, UPC). This sound can sometimes be transmitted along the pipe hundreds of meters away. When the pipeline is buried underground, the soil bricks and stones of the buried layer will also be impacted by the pressurized water to form a weak vibration of the ground. This vibration is transmitted to the vicinity of the ground, so a relatively low-frequency sound can be detected.

When the liquid in the pipeline flows, if there are holes or cracks in the pipeline, the liquid or gas will produce violent vortexes and jet sounds when it flows out through these holes. The water pipe line detector receives these sound signals through a highly sensitive sensor, converts them into electrical signals for processing and analysis, and finally determines the location of the leak. This process includes steps such as vibration caused by water flow, propagation of sound waves, and detection of sound waves. At the same time, the pressurized water may flush out a gap near the impact port and produce a swirling disturbance of the water flow, sometimes accompanied by the sound of bubbles.

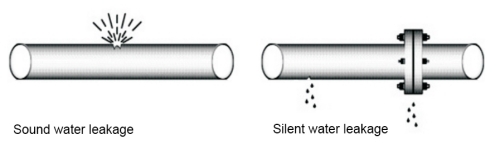

When the crack in the pipeline vibrates, it may also cause additional vibrations in other parts of the pipeline. These vibrations are all caused by water leakage, but the factors of direct vibration are not the same, so the leak detector may detect a mixed sound caused by one of the vibration factors or several vibration factors, which are different under different conditions, which forms the variability and complexity of the water leakage sound. Another situation is water leakage that does not make a sound (called silent water leakage, such as water seepage and dripping caused by poor valve sealing). In this case, the pipeline needs to be pressurized (usually recommended to pressurize to 0.6-0.8Mpa) before detection can be carried out.

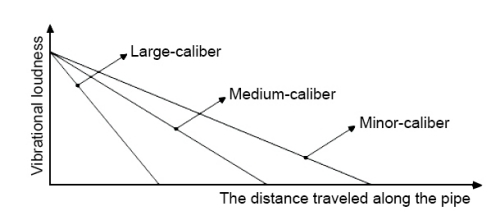

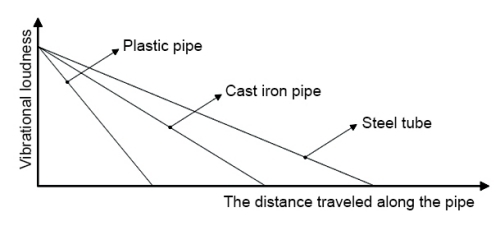

If the measuring point is on the pipeline wall and accessories, the sound is mainly transmitted along the pipeline, which will vary with factors such as the material, thickness, caliber of the pipe, and the distance between the leaking points.

When a pipeline leaks, the water flow will generate specific sound wave signals, which will propagate along the pipeline and reflect and refract at different parts of the pipeline. The detector's sensor can receive these sound wave signals and convert them into electrical signals. The built-in signal processing system analyzes and processes the electrical signals to determine the location of the leak.

How to Detect Water Leaks?

We have learned about the possible causes of water leaks in pipes. In order to better understand how the water leak finder detects water leaks, we need to know how the water leak sound propagates in the medium and the characteristics of the intensity and frequency changes of the water leak sound when propagating along the pipe.

- The sound source (vibration center point) of the water leakage sound is a point near the leak. In the soil layer, if the medium is uniform, this vibration will expand in all directions in the form of a spherical wave. The farther the propagation distance, the smaller the vibration amplitude; the closer the propagation distance, the stronger the vibration. The farther away from the top, that is, the farther from the leak point, the weaker the vibration. Therefore, it can be said qualitatively that the signal is strongest directly above the leak point, so finding the location of the leak point on the ground is to find the location where the ground vibration is the strongest. This is the most basic basis for the listening method to detect the leak point.

- The soil layer has a certain absorption effect on sound vibration, especially related to the attenuation of high-frequency sound. Therefore, for the same water leakage situation, it is easier to hear the water leakage sound in the shallow buried area, while it is relatively difficult when the buried layer is deep, and the sound sounds deeper, that is, there are more low-frequency components.

- When the pipeline is buried in different types of soil layers, the soil layer is dense and elastic, and the loss of acoustic vibration transmission is small. It is easier to detect with a blockage detector; however, it is difficult to excite vibration for soft or too-hard soil layers, and detection is relatively difficult. Grass and silt on the surface are factors that are not conducive to detecting vibration. In addition, since the vibration of plastic pipes is weak when leaking, it is more difficult to detect plastic pipe leakage than metal pipes.

- Smaller-caliber metal pipes are easy to vibrate, and the loss of transmission along the pipeline is small. Therefore, the propagation of water leakage along small-caliber metal pipes is very far, generally up to tens of meters or even hundreds of meters. We can use this to initially understand whether there is a leak within a few tens of meters. In addition, the attenuation of pipes of different materials along the pipeline is also different. Metal pipes propagate farther than non-metallic pipes.

In short, due to different leakage conditions, different factors that cause vibration, different propagation conditions such as buried media, and different properties of detection instruments, the sound of water leakage heard by the detector under different conditions is different. In addition, people use different tools and instruments for detection, and the sensitivity of the detection equipment itself, frequency characteristics, and other factors will also make the sounds heard by the human ear different. The detector should understand these basic principles so that it can have a clearer analysis of the variability of water leakage sound in actual detection, which is also conducive to judging the leakage point and distance.