A surface roughness tester is an instrument used to measure the surface roughness of an object. It evaluates the smoothness and roughness of an object's surface by measuring the tiny fluctuations on the surface. Surface roughness testers are widely used in machinery manufacturing, the automotive industry, aerospace, and other fields, and are very important for ensuring product quality and performance.

This article will briefly explain its working principle so that users can better understand the surface roughness meter.

Understand the Basic of Surface Roughness Tester

A roughness tester is a geometrical measuring instrument used to measure the surface roughness of an object. It is typically used to inspect the perfection of machined surfaces, as it can accurately measure the surface's irregularities to reflect the relationship between the surface and the machining process. Roughness testers come in various forms, including roughness meters, profilometers, contact stylus instruments, and portable roughness scanners. These devices measure surface irregularities in different ways, but with technological advancements, more and more instruments are integrating the functions of measuring both surface roughness and object surface irregularities.

The working principle of the surface roughness tester is mainly based on mechanical and electronic technology. It usually consists of a measuring head, a sensor, an amplifier and a display.

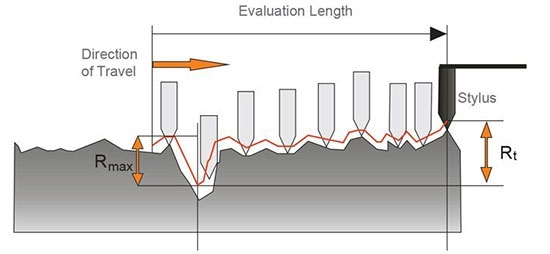

When measuring with a surface roughness gauge, the measuring head is first placed on the surface to be measured. There is a very sensitive sensor at the bottom of the measuring head that can detect the tiny undulations in the surface. As the measuring head slides over the surface, the sensor records the height and spacing of the undulations.

The fluctuation data recorded by the sensor is transmitted to the amplifier for signal amplification and processing. The amplifier amplifies the sensor signal and converts it into a digital signal for further processing and analysis. Such signal processing can eliminate the influence of environmental factors on the measurement results and ensure the accuracy and stability of the measurement.

The processed data will be displayed on the display for users to read and analyze. Surface roughness testers usually provide a variety of measurement parameters, such as Ra (surface average roughness), Rz (maximum peak height), Rt (total height) , Rp (peak height), etc. Users can select appropriate parameters for measurement according to actual needs.

Working Principle of Surface Roughness Tester

- Probe Contact: Place the test sample on the instrument, which has a movable probe above it. The probe is a fine, pointed tip, usually made of hard metal, that can leave a mark on the surface of the test sample.

- Motion Path: The probe starts moving from a specific starting point and follows a predefined path to the end. This path is usually linear or rotational.

- Measurement Force: While the probe contacts the sample surface, the roughness tester applies a predefined force. The magnitude of this force is usually fixed to ensure comparability of results across different samples.

- Data Recording: As the probe moves and touches the surface of the sample, the tester measures the height variations at each contact point. By recording these height data points, the tester calculates surface roughness parameters such as Rz, Ra, and Rq.

- Data Processing: The tester is usually equipped with a computer for data processing. The computer generates a numerical chart or report based on the measurement results, allowing the user to analyze and compare the data.

In addition to basic measurement functions, some advanced surface roughness testers also have data storage and analysis functions. Users can store measurement results in the tester or transfer them to a computer via Bluetooth or USB interface for further analysis and processing. These functions make the surface roughness tester a powerful tool that can help users better understand and control the quality of the surface of an object.

The working principle of the surface roughness tester is simple and clear, but some details need to be paid attention to when using it. First, the placement of the measuring head should ensure that it is perpendicular to the surface to avoid measurement errors. Secondly, the stable sliding of the measuring head should be maintained during the measurement process to ensure the accuracy of the data. In addition, in order to obtain more accurate measurement results, it is recommended to perform multiple measurements and take the average value.

In summary, the surface roughness tester evaluates the roughness of an object by measuring the tiny fluctuations on its surface. Its working principle is based on mechanical and electronic technology, and through the coordinated work of components such as the measuring head, sensor amplifier and display, it can accurately measure and evaluate the surface roughness. The surface roughness tester plays an important role in modern industrial production, helping users ensure the stability of product quality and performance.