The high precision roundness tester machine ensures exceptional accuracy with precision circular gratings for data acquisition, suitable for automotive, aerospace, and manufacturing applications. This roundness measuring machine offers arc processing, automatic contour discontinuity detection, and manual elimination to reduce human error. Compatible with Windows XP and 7, it integrates easily into existing setups.

High Precision and Durability in Roundness Testing

- The roundness tester has a high precision air-bearing spindle, which hardly wears out and maintains accuracy for a long time.

- The instrument also collects data through a high-precision encoder for high accuracy and stability.

Flexibility and System Compatibility of Roundness Measuring Instrument

- Part of the arc can also be measured and processed.

- Automatic identification of contour discontinuities, with automatic or manual elimination function.

- Support winXP, win7 system.

Application

The roundness tester is used in high-precision industries like automotive, aerospace, machinery, and electronics. It measures roundness errors in components such as bearings, gears, and shafts, ensuring they meet strict tolerances. It helps identify machining issues, improve efficiency, enhance quality, reduce scrap, and lower costs. Roundness testers are also valuable in R&D for product design and optimization.

Automotive Industry

Electronics Industry

Machinery Manufacturing

Aerospace

| Model | SISCO-RT-1000AE | |

| Measuring Range | Max. Dia. | Φ380mm (expandable) |

| Min. Inner Dia. | Φ5mm | |

| Max. Height | 420mm | |

| Spindle Accuracy | Radial Error | ±(0.025+5H/10000)μm |

| Axial Error | ±(0.02+6X/10000)μm | |

| Workbench | Table Dia. | Φ200mm |

| Rotation Dia. | Φ380mm | |

| Load Wt. | 25kg | |

| Adjustment Range | Adjust the eccentricity ±2mm; adjust the level ±1° | |

| Rotation Speed | 0-12 rpm | |

| Horizontal Arm | Horizontal Moving Distance | 150mm |

| Moving Speed | 0.5-6mm/s or manual | |

| Sensor | Range | 500μm (Radius difference) |

| Resolution | 0.005μm | |

| Stylus Shape | φ2mm Ruby tip (φ1mm、φ0.5mm optional) | |

| Meas. Force | 1-12g | |

| Data Acquisition | Imported grating 7200 points/cycle | |

| Magnification | Arbitrary to maximum 200,000 times | |

| Air Source | 0.45~0.80Mpa | |

| Air Consumption | ≥0.2 m³/min | |

| Power | AC 220V/110V ±10% 50Hz | |

| Environmental Conditions | Temperature (T): 10~30℃; relative humidity (RH): <85% | |

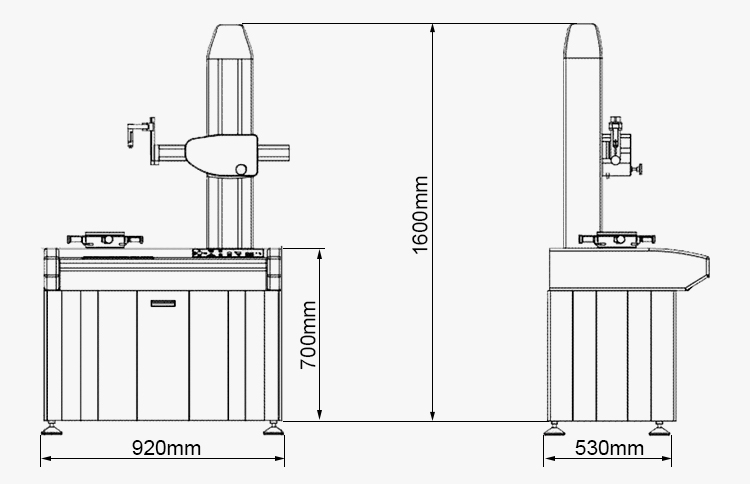

Dimension

Q1: What is a roundness tester?

A1: A roundness tester is a precision measurement tool used to evaluate the roundness or circularity of a workpiece. It measures how closely a part conforms to a perfect circle by detecting deviations in its surface profile. The tester typically uses a high-precision probe that rotates around the part, collecting data to analyze any irregularities or deviations from ideal roundness. Roundness measuring machines are essential in industries such as automotive, aerospace, and precision manufacturing, where even the smallest deviations can impact the performance and quality of components like shafts, bearings, and gears. These testers help ensure that parts meet strict tolerances and maintain high levels of quality and functionality.

Q2: How does a roundness tester work?

A2: A roundness tester works by measuring the deviations of a workpiece's surface from a perfect circle. The part is placed on a rotating spindle, and a high-precision probe contacts the surface as the workpiece spins. The probe collects data points around the circumference, detecting any variations in radius. The tester’s software then analyzes this data, comparing it to an ideal circle, and calculates the roundness errors. These errors are displayed in numerical or graphical form, providing insights into the part’s quality and precision. The roundness measuring tool ensures that components meet stringent tolerances, critical for industries like automotive, aerospace, and precision manufacturing.

Q3: What is the difference between roundness tester and cylindricity tester?

A3: A roundness tester measures the deviation of a workpiece's surface from a perfect circle, focusing on assessing the roundness or circularity of a part along its circumference. It is primarily used to check the geometry of parts like shafts, bearings, and rings, ensuring they maintain consistent circularity. In contrast, a cylindricity tester measures the overall roundness and straightness of a cylindrical part, checking both its circularity and the straightness of its axis. While a roundness tester focuses solely on the cross-sectional shape, a cylindricity tester evaluates the entire geometry of the cylinder, including any deviations along the length of the part, ensuring that the part is both round and straight along its axis. Thus, cylindricity testing provides a more comprehensive analysis of a cylindrical part’s geometry, making it suitable for applications where both roundness and straightness are critical.

Tips: The usage requirement of the roundness tester machine

- Air supply: 0.45~0.80Mpa.

- Air flux: ≥0.2 m³/min.

- Power supply: AC 220V/110V ±10% 50Hz.

- Environment requirements: Temperature: 10~30℃; RH: <85%.

- No obvious vibration.

- Separated grounding wire.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.