The glass tube rotameter flowmeter offers a full range of flow measurement parameters and multiple connection options to suit various applications. Designed for water, gas, liquid, and oil, it provides an all-in-one solution with pressure resistance and corrosion protection for reliable performance.

Precision Measurement and Clear Readability Assurance

- High-clarity Scale: The clear scale of the rotameter ensures easy and precise reading, eliminating reading errors.

- Acrylic Material: Made of acrylic for enhanced durability and more precise measurements.

- Premium Material Selection: The float is made of agate jade stainless steel, with different materials corresponding to different flow rates for more accurate measurements.

Versatile Connection Options and Easy Installation

- Threaded Connection: Features an internal G1/4" male thread for easy installation and improved sealing performance.

- Optional Connection Fittings: Quick-connect fittings (for hoses), threaded fittings (internal/external threads), ferrule fittings (for rigid pipes), and barb fittings (for hoses). Customizable fitting sizes available upon request.

Applications

SISCO glass tube rotameter is widely used across various industries, including petrochemical, water supply, wastewater treatment, slurry and pulp, pharmaceutical and medical, and food processing. It is compatible with multiple media such as water, gas, oil, and chemical products, making it a versatile solution for different industry applications—all in one device!

Gas

Oil

Chemical Products

Water

| Model | SISCO-LZB-3W/3WB | SISCO-LZB-4W/4WB | SISCO-LZB-6W/6WB | SISCO-LZB-10W/10WB | |

| Diameter(mm) | 3 | 4 | 6 | 10 | |

| Measure Range | Water | (0.4~4)ml/min | (16~160)ml/min | (40~400)ml/min | (0.1~1)L/min |

| (0.6~6)ml/min | (25~250)ml/min | (60~600)ml/min | (0.16~1.6)L/min | ||

| (1~10)ml/min | (40~400)ml/min | / | / | ||

| (1.6~16)ml/min | / | / | / | ||

| (2.5~25)ml/min | / | / | / | ||

| (4~40)ml/min | / | / | / | ||

| (6~60)ml/min | / | / | / | ||

| (10~100)ml/min | / | / | / | ||

| Air | (6~60)ml/min | (0.3~3)L/min | (1~10)L/min | (3~30)L/min | |

| (10~100)ml/min | (0.6~6)L/min | (1.5~15)L/min | (5~45)L/min | ||

| (16~160)ml/min | (0.7~7)L/min | / | / | ||

| (25~250)ml/min | / | / | / | ||

| (40~400)ml/min | / | / | / | ||

| (60~600)ml/min | / | / | / | ||

| (0.1~1)L/min | / | / | / | ||

| (0.16~1.6)L/min | / | / | / | ||

| Interface Mode | Pagoda, ferrule, quick-insert, thread | ||||

| Accuracy Level | ±4% | ||||

| Temperature | Ambient temperature: 0~50℃; Rated temperature: 0~60℃ |

||||

| Display Parameters | Instantaneous flow rate | ||||

| Display Mode | Scale display | ||||

| Pressure Resistance | ≤0.6MPa |

||||

Note: Please contact us for other measure ranges.

Details

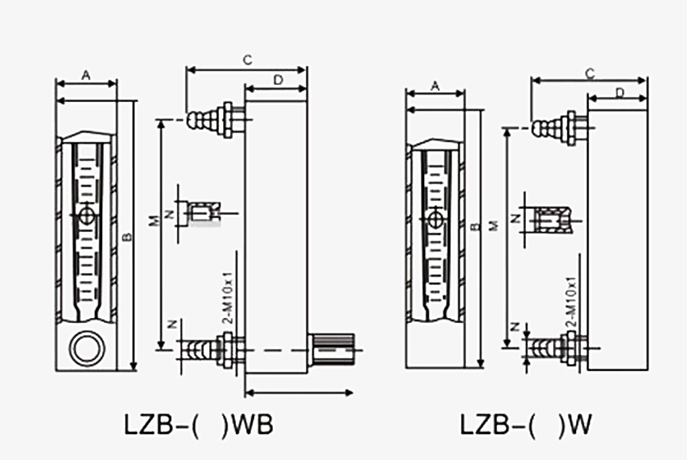

| Model | Diameter(mm) | Size | Metal Pipe Fittings | Mounting Holes | ||||||

| A | B | C | D | E | M | N (Hose Fitting) | ||||

| LZB-3WLZB-3WB | 3 | 26 | 136 | 50 | 24 | <50 | 116 | Φ8 | M10x1 | 2-Φ11 |

| LZB-4WLZB-4WB | 4 | 28 | 136 | 56 | 27.5 | <52 | 116 | Φ8 | M10x1 | 2-Φ11 |

| LZB-6WLZB-6WB | 6 | 28 | 136 | 58 | 29.5 | <55 | 116 | Φ10 | M10x1 | 2-Φ11 |

| LZB-10WLZB-10WB | 10 | 28 | 160 | 60 | 29.5 | <55 | 140 | Φ11 | M10x1 | 2-Φ11 |

Q1: What is a glass tube rotameter?

A1: A glass tube rotameter is a variable area flowmeter used to measure the flow rate of liquids and gases in a transparent, vertically oriented glass tube. It operates based on the principle of a floating element (float) moving up and down within the tube as the fluid flows through it. The position of the float corresponds to the flow rate, which is typically marked on a scale along the tube for easy reading. Glass tube rotameters are widely used in industries like chemical processing, water treatment, pharmaceuticals, and food processing due to their high visibility, corrosion resistance, and accurate flow measurement capabilities.

Q2: What media can the rotameter measure?

A2: The glass tube rotameter can measure a wide variety of media, including liquids, gases, and oils, making it a versatile flow measurement tool. It is commonly used to measure water, air, and other gases, as well as chemical solutions, oils, and other liquid substances. The rotameter's design allows it to handle different fluid properties by selecting the appropriate float material and scale, ensuring precise measurement across various applications in industries like petrochemicals, pharmaceuticals, food processing, and water treatment. Its flexibility in handling multiple media types makes it an essential tool in many industrial settings.

Q3: What are the reasons for large measurement errors?

A3: Short straight pipe sections: If the straight pipe sections before and after the flowmeter are too short, and elbows, valves, and other components that can interfere with the fluid flow state are installed directly in front of the flowmeter, it will affect the accuracy of the measurement.

Incorrect installation: Misalignment between the flowmeter and the connecting pipeline, or improper installation of gaskets, can form a throttling component, affecting the measured medium flow.

Density change of the medium: For liquid media, a large change in density can cause significant errors.

Tips: How does a rotameter work?

A rotameter works by having a fluid (liquid or gas) enter at the bottom of a vertically - mounted tapered tube. Inside the tube is a float. As the fluid flows upward, it exerts an upward force on the float. The position of the float is determined by the balance between the upward force from the fluid flow and the downward force due to the float's weight and friction. The flow rate is related to the position of the float; as the flow rate increases, the float rises higher in the tube. The tube is calibrated so that the position of the float corresponds to a specific flow rate, which can be read from a scale on the side of the tube.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.