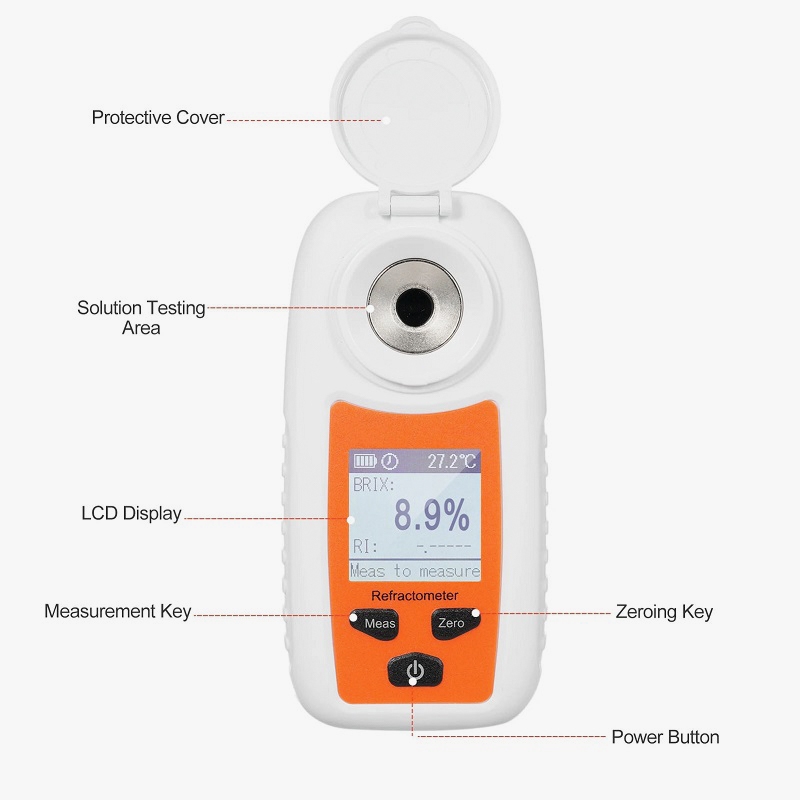

The digital refractometer for sale online adopts a high-quality optical refractive sensor for quick measurements in seconds, with a high accuracy of ±0.2% Brix and a resolution of 0.1%. Buy a cheap digital refractometer with a measuring range of 0-35% Brix.

Digital Refractometer Design Details

- Bilingual switching between Chinese and English. When turned off, press and hold the digital refractometer and power buttons for 6 seconds to switch between Chinese and English.

- Optical refractive sensor. Accurate digital refractometer measurement, more convenient with dropper measurement.

- Battery compartment design. Using 3 1.5V AAA batteries (NOT included).

- Anti-slip Design on Both Sides. Ergonomic anti-slip design on the side.

Digital Refractometer Function

- Automatic temperature compensation (ATC) function. For immediate and accurate calibration reading, not affected by the environment. reducing measurement errors caused by different temperatures.

- Dust-proof protective cover design. Well protected by the optical prism, easy to clean the digital refractometer, is suitable for measuring various solutions.

Applications

SISCO digital refractometers are often used in the food and beverage industry, flavor, and fragrance industries. The digital refractometer can measure the brix or concentration or salinity of raw materials or semi-finished products and finished products, or online detection of concentration in the production process. Test samples such as cola, fruit juice, tea drinks and other sugar-sweetened beverages, jam, honey, sugar, syrup and other sugar-sweetened foods, condiments, sauces or soups, soy milk, vegetable protein, etc.

Maple Syrup

Beer

Wine

Fruits

| Model | SISCO-DR-ST335A |

| Range | 0~35%Brix |

| Temperature Compensation | 10℃~40℃ |

| Ambient Temperature | 10℃~40℃ |

| Resolution | 0.1% |

| Accuracy | ±0.2%/±0.5% |

| Battery | 3*1.5V AAA batteries |

| Dimension | 113.15*56.3*26.1mm |

| Weight | 108g |

Details

Q1: What is a refractometer?

A1: A refractometer is a scientific instrument used to measure the refractive index of a substance. The refractive index is a measure of how much the speed of light changes when passing through a substance. Refractometers are commonly used in various industries such as food and beverage, pharmaceutical, chemical, and automotive industries, to name a few.

Refractometers work by shining a beam of light through a sample and measuring the angle at which the light is bent or refracted as it passes through the substance. This angle is then compared to a known scale or reference chart to determine the refractive index of the substance. Refractometers can be used to measure a variety of substances such as liquids, gases, and solids, and are particularly useful for measuring the concentration of dissolved solids in a liquid sample, such as sugar content in fruit juice or wine.

Q2: How does a refractometer work?

A2: A refractometer works by measuring the extent to which a beam of light is refracted, or bent, as it passes through a sample. The amount of refraction depends on the refractive index of the sample, which is a measure of how much the speed of light changes when passing through the substance.

The basic design of a refractometer typically consists of a light source, a prism, a sample plate or well, and a detector. The prism is made of a material with a known refractive index, such as glass or plastic, and is designed to refract the incoming light beam at a specific angle. The sample is placed on the sample plate or well, and the refracted light passes through the sample before reaching the detector.

The detector measures the angle of the refracted light and compares it to a known scale or reference chart to determine the refractive index of the sample. This can be done manually by reading the scale or chart, or digitally through a display screen or computer software.

Different types of refractometers may use different methods for measuring the angle of the refracted light, such as through a handheld device, a benchtop instrument, or an inline sensor. Some refractometers also incorporate temperature compensation to account for the effect of temperature on the refractive index of the sample. Overall, refractometers are versatile instruments that can be used to measure a wide range of samples in various industries, from food and beverage to pharmaceuticals and beyond.

Q3: Why do you need a refractometer?

A3: A refractometer is a valuable tool in many industries and applications because it allows for quick, accurate, and non-destructive measurements of the refractive index of a sample. There are several reasons why you might need a refractometer, including:

- Measuring dissolved solids: Refractometers are commonly used to measure the concentration of dissolved solids in a liquid sample, such as sugar content in fruit juice or wine. This can be useful in industries such as food and beverage, where the quality and consistency of products depend on accurate measurements of ingredients.

- Quality control: Refractometers can be used as a quality control tool to ensure that products meet certain specifications or standards. For example, in the pharmaceutical industry, refractometers can be used to check the purity and consistency of drugs.

- Research and development: Refractometers are often used in research and development to study the physical and chemical properties of substances. They can be used to investigate the refractive index of new materials, determine the composition of unknown substances, and to study the effects of temperature and pressure on the refractive index.

- Process monitoring: Refractometers can be used as inline sensors to monitor processes and ensure that they are running smoothly. For example, in the chemical industry, refractometers can be used to monitor the concentration of solutions in real time, helping to optimize production processes and reduce waste.

Tips: How to calibrate a digital refractometer?

- Distilled Water: Start by calibrating with distilled water at the temperature specified by the manufacturer.

- Zero Setting: Place a few drops of distilled water on the prism, close the lid, and press the calibration button to set the device to zero Brix.

- Calibration Solutions: Use known concentration solutions to check and adjust the readings for more accuracy.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.