Buy an electronic depth micrometer in factory price. Unlike traditional depth micrometers, the digital version features an electronic display, providing instant readings. Key advantages of a digital depth micrometer include ease of reading, reduced human error, and data output capabilities for recording measurements. It typically offers a resolution of 0.001 mm (or 0.00005 inches).

Quality Design of DIgital Depth Micrometer

- The detection rod can be easily removed.

- A large screen with digital display, makes this depth micrometer reading clear.

- Smooth grinding of measuring surfaces to guarantee measurement accuracy.

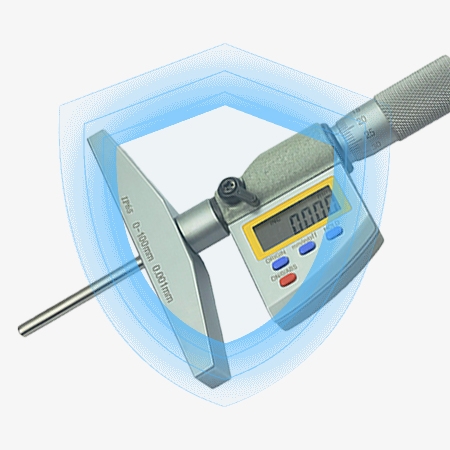

IP65 Protection of Digital Depth Micrometer

- Enhanced Durability. Resistant to dust, dirt, and water, making it suitable for rugged industrial environments.

- Ease of Cleaning. Electronic depth micrometer can be wiped down or lightly washed without damaging the internal electronics.

- Low Maintenance. Less frequent cleaning and recalibration are required due to resistance to external particles.

Applications

SISCO electronic depth micrometer is a precision measuring instrument used to measure the depth of holes, slots, recesses, and other surface variations with high accuracy. It consists of a base, a spindle, and a digital display for reading measurements. The digital display provides quick and easy readings, reducing the chances of human error. Digital depth gauge micrometer is widely used in manufacturing, machining, automotive, and quality control industry. It helps ensure that machined components meet design specification.

Construction Industry

Automotive Industry

Manufacturing Industry

Aerospace Industry

| Model | SISCO-DM-QFCHLIP65-100 |

| Resolution | 0.001mm/ 0.00005" |

| Measuring range | 0-100mm |

| Operating temperature | 0 ℃~40 ℃ |

| Storage temperature | -10 ℃~60 ℃ |

| Setting speed | 30mm/s |

| Number of Rod | 4 (0-25mm/ 25-50mm/ 50-75mm/ 75-100mm) |

| Battery | CR2032 |

| Battery life | 2 years |

| Protection level | IP65 |

| Net weight | 720g |

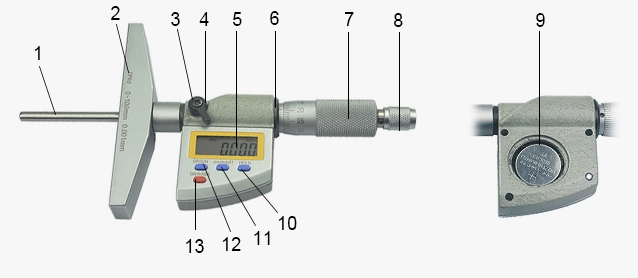

Structure:

| 1. Spindle | 2. Anvil | 3. Frame | 4. Locking device | 5. LCD screen |

| 6. Sleeve | 7. Thimble | 8. Ratchet stop | 9. Battery cover | 10. HOLD/DATA button |

| 11. mm/in button | 12. ORIGIN button (0 position setting) | 13. ON/0/ABS button |

Q1: How does a digital depth micrometer work?

A1: A digital depth gauge micrometer is a precision instrument used to measure the depth of holes, recesses, or grooves. It consists of a micrometer spindle, an anvil, and a digital display. The spindle is adjusted by turning the thimble, which moves the anvil towards the object being measured. The depth is calculated by subtracting the reading of the spindle's position from a fixed reference point. The digital display shows the depth measurement directly in units like millimeters or inches, providing quick and accurate readings. This tool is often used in manufacturing, engineering, and quality control for precise depth measurements.

Q2: What are the main advantages of using a digital depth micrometer?

A2: A digital depth micrometer offers several key advantages over traditional mechanical micrometers. First, it provides precise digital readings, reducing the risk of human error and increasing measurement accuracy. The digital display is easy to read, even in low-light environments, and eliminates the need for manual interpretation of dial scales. This makes it faster and more convenient, improving productivity. Its ergonomic design makes it comfortable to use, minimizing operator fatigue during prolonged use.

Q3: What factors can affect the accuracy of digital depth micrometer?

A3: These include environmental conditions such as temperature, humidity, and dust, which can influence both the instrument and the material being measured. Wear and tear on the micrometer's components, especially the probe, can also cause inaccuracies. Incorrect calibration or using the micrometer with improper techniques, such as inconsistent pressure during measurement, can lead to errors. Additionally, the quality of the micrometer's components, battery life, and the resolution of its digital display can all impact measurement precision. Regular maintenance and calibration help mitigate these issues.

Tips: How do you properly maintain and store digital depth micrometer?

To properly maintain and store a digital depth gauge micrometer, it is essential to keep it clean and free from dirt, dust, or any contaminants. After each use, wipe the micrometer’s measuring surfaces with a clean, dry cloth. If necessary, use a lint-free cloth lightly dampened with alcohol to remove stubborn debris. Avoid using harsh chemicals that could damage the instrument. Checking the battery regularly, and replace it when needed to ensure accurate readings.

When storing the micrometer, place it in a protective case or box to avoid exposure to moisture, extreme temperatures, or direct sunlight, as these conditions can cause corrosion or damage. Ensure the instrument is stored in a dry, cool environment, and avoid dropping it or subjecting it to shock. Additionally, store the micrometer with the measuring faces retracted to prevent any wear or deformation of the components.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.