Ceramic gauge blocks offer excellent structural stability, superior corrosion and wear resistance, and high hardness. They withstand high temperatures without deformation and are 20–40 times more wear-resistant than standard steel. Even in extreme acidic or alkaline environments, they maintain their shape, ensuring precise measurements.

High-Durability Ceramic for Reliable, Low-Maintenance Measurement

- Ceramic gauge blocks are extremely hard and wear-resistant, lasting 5–10 times longer than steel and 4–5 times longer than carbide, with extended calibration intervals.

- Ceramic gauge blocks resist corrosion and common chemicals, require no rust protection, and can be stored long-term without special care.

Durable Markings and Safe Use in Specialized Environments

- Each ceramic block in the set is engraved with its corresponding number to prevent mix-ups during use and ensure smooth workflow. Laser-etched markings are wear-resistant, durable, and won’t fade over time.

- Ceramic gauge blocks are non-magnetic and non-conductive, making them suitable for use in special environments.

Applications

Ceramic gauge blocks are used for position checking, hole size measurement, hole-to-hole distance inspection, and can also serve as go/no-go gauges and for measuring hole depth. They are essential tools for standardized hole inspection and are used with advanced international laser measuring equipment. Widely applied in fields such as circuit boards, electronic board, molds, and precision machinery manufacturing.

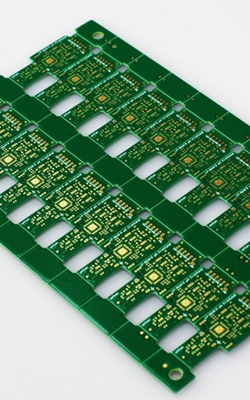

Circuit Boards

Electronic Boards

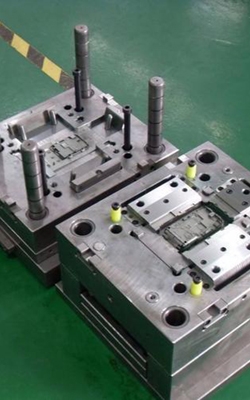

Molds

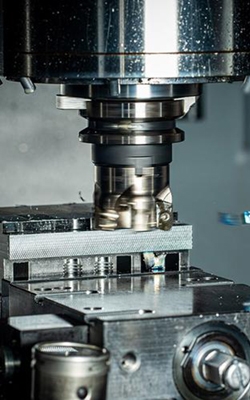

Precision Manufacturing

| Model | SISCO-CGB-MH | |||

| Material | Zirconia ceramic material | |||

| Grade | 0/1* | |||

| Ceramic Gauge Block Set Specs | ||||

| Size | Interval | Number | ||

| 38 pcs | 1 | / | 1 | |

| 1.005 | / | 1 | ||

| 1.01-1.09 | 0.01 | 9 | ||

| 1.1-1.9 | 0.1 | 9 | ||

| 2.0-9.0 | 1 | 8 | ||

| 10-100 | 10 | 10 | ||

| 87 pcs | 1.001-1.009 | 0.001 | 9 | |

| 1.01-1.49 | 0.01 | 49 | ||

| 0.5-9.5 | 0.5 | 19 | ||

| 10-100 | 10 | 10 | ||

| Grade 0 & 1 Accuracy Specs | ||||

| Nominal length (1n) | Grade 0 Accuracy Specifications | Grade 1 Accuracy Specifications | ||

| Change amount | Limit deviation(±) | Change amount | Limit deviation(±) | |

| 1n≤10mm | 0.10um | 0.12um | 0.16um | 0.20um |

| 10<1n≤25mm | 0.10um | 0.14um | 0.16um | 0.30um |

| 25<1n≤50mm | 0.10um | 0.20um | 0.18um | 0.40um |

| 50<1n≤75mm | 0.12um | 0.25um | 0.18um | 0.50um |

| 75<1n≤100mm | 0.12um | 0.30um | 0.20um | 0.60um |

| 100<1n≤150mm | 0.14um | 0.40um | 0.20um | 0.80um |

Notes*:

- Single gauge blocks are Grade 1.

- The sets are Grade 0.

Single Ceramic Gauge Blocks Dimension

Q1: What are the different grades of gauge blocks?

A1: Gauge blocks come in different grades based on their precision and intended use. The main grades include:

- K Grade (Calibration Grade) – Highest accuracy, used in national metrology labs for primary calibration.

- Grade 00 – High precision, used in calibration labs and inspection rooms.

- Grade 0 – Precision measurement for tool rooms and high-accuracy machining.

- Grade 1 – General industrial inspection and high-precision manufacturing.

- Grade 2 – Standard for workshops and production environments.

- Workshop Grade – Lower precision, used for routine machine setup.

Q2: How to select the right gauge block set?

A2: Selecting the right gauge block set depends on accuracy requirements, material, grade, and measurement system. Consider the following:

- Accuracy & Grade – Choose Grade K or 00 for laboratory calibration, Grade 0 for high-precision machining, and Grade 1 or 2 for general industrial use.

- Material – Steel is durable, ceramic resists corrosion, and tungsten carbide offers extreme wear resistance.

- Measurement System – Select metric (mm) or imperial (inch) based on your industry standards.

- Number of Blocks – A larger set (81 or 103 pieces) provides more versatility, while smaller sets (36 or 46 pieces) suit basic applications.

Gauge blocks help maintain precision and consistency in machine alignment and calibration.

Q3: What is the difference between metric and imperial gauge block sets?

A3: The difference between metric and imperial gauge block sets lies in their unit of measurement and step increments. Metric gauge blocks use millimeters (mm) as the standard and typically follow increments such as 1.001 mm, 1.002 mm, etc. Imperial gauge blocks use inches, often following increments like 0.1001 inches, 0.1002 inches, and so on. While both sets serve the same purpose—precise length measurement and calibration—their use depends on the measurement system required for specific tools, industries, or regions.

Tips: How to clean ceramic gauge blocks?

- Use a lint-free cloth or microfiber wipe to remove dust and debris.

- Apply alcohol or a mild solvent (like isopropyl alcohol) to gently clean the surface.

- Avoid abrasive materials that could scratch the ceramic.

- Let them air dry or wipe dry with a clean cloth.

- Do not oil ceramic blocks.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.