SISCO rotating laser level for sale online. The scanning speed of the green rotary laser level can be adjusted at 0, 60, 120, 300 and 600rpm, features an electronic automatic self-leveling function, delivering horizontal or vertical laser beam, adjusting and finding a level with ±5°self leveling range, which is perfect for leveling on large areas and job sites.

Remote control operation

- The infrared rotary laser level can be controlled remotely. The remote control panel has nine keys. Each time a key is pressed, the indicator light on the panel will flash, indicating that a signal has been sent.

- The rotary laser level is compatible with a remote control for easy adjustments and operation from a distance.

- The remote control is compact and easy to carry, with a clip or lanyard for convenient access during projects.

The laser level design with leveling mode

- The instrument can be controlled to be within 5° of manual or automatic mode, and the instrument is automatically leveled.

- The rotary laser level has an efficient self-leveling mechanism that quickly adjusts to create a perfectly level line, reducing setup time and increasing accuracy.

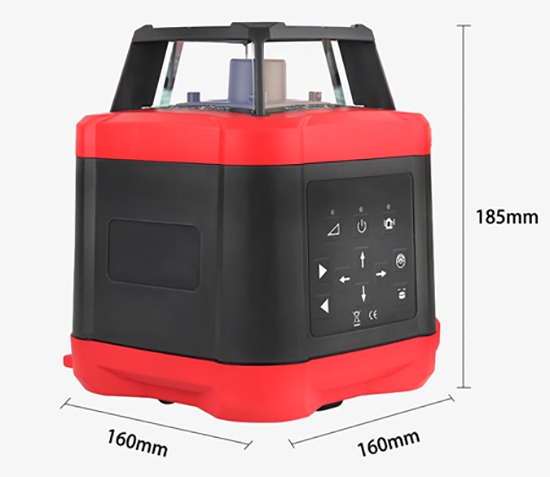

Dimension

Applications

SISCO high-intensity laser level is a common measuring tool for measuring angles. The high-precision green light level can be widely used in metallurgical steel plate cutting, stone cutting, wood cutting, machine vision and other fields.

Stone Cutting

Wood Cutting

Machine Vision

Metallurgical Steel Cutting

| Model | SISCO-LL-LM581LD |

| Light Source | LD laser diode (green) |

| Laser Wavelength | 505-532 nm |

| Automatic Leveling Range | ±5° |

| Working Measurement Range (Diameter) | 500m (with detector) |

| Adjustable Rotation Speed | 0/60/120/300/600 rpm |

| Directional Scanning | 0°, 10°, 45°, 90°, 180° |

| Slope Setting Range | ±5° (bidirectional) |

| Measurement Accuracy | ±20" |

| Laser Plummet Accuracy | ±1mm/1.5m |

| Remote Control Distance | 20m |

| Power Supply | (4*4000mAh Ni-MH rechargeable batteries in series) NiMH rechargeable battery pack |

| Continuous Working Time | 20 hours |

| Working Temperature | -20℃~50℃ |

| Size | 160*160*185mm |

| Weight | 2 kg |

Packing List

- 1*Infrared rotary laser level

- 1*Receiver (clamp)

- 1*Protective glasses

- 1*Laser target

- 1*Remote controller

- 1*Charger

- 1*Instruction manual

- 1*Tool box

Q1: Can a rotary laser level be used outdoors?

A1: Yes, rotary laser levels can be used outdoors. However, the visibility of the laser beam can be an issue in bright sunlight. Using a laser detector can help you locate the beam and maintain accuracy over longer distances.

Q2: What are laser levels used for?

A2: A laser level tool is a construction tool that uses a laser to detect the vertical position of the object. It's used for measuring distances and heights, as well as for aligning objects on different levels.

Q3: What is a rotary laser level and how does it work?

A3: A rotary laser level is a leveling tool that projects a 360-degree laser beam around a room to create a level line. It consists of a laser emitter that spins rapidly to create a horizontal or vertical plane, which can be used for various leveling and alignment tasks.

Tips: What is the difference between a self-leveling and a manual rotary laser level?

The primary difference between a self-leveling and a manual rotary laser level lies in their leveling mechanisms and ease of use. A self-leveling rotary laser level automatically adjusts itself to achieve a perfectly level plane, thanks to its internal pendulum or electronic leveling mechanism. This makes it highly accurate and user-friendly, as it reduces setup time and minimizes human error. It also often includes features like a tilt alarm to maintain consistent accuracy. On the other hand, a manual rotary laser level requires the user to manually adjust the device using built-in bubble vials. This process is more time-consuming and prone to human error, which can affect accuracy. However, manual models are generally more affordable and are suitable for simpler tasks where extreme precision is not critical. In summary, self-leveling rotary laser levels offer greater accuracy and convenience at a higher cost, while manual models are cost-effective but require more effort and attention to achieve accurate results.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.