SISCO contactless high temperature infrared thermometer equipped with four professional measurement modes, a high-resolution TFT color LCD, date and time display, trigger lock, scheduled measurement, storage for 999 data sets, data output in PDF and CSV formats, buzzer alarm, and other features, it allows you to complete your work faster, better, and more efficiently.

High-Efficiency Temperature Measurement

- 2.4-inch TFT LCD color screen display.

- Distance-to-spot ratio: 55:1.

- Trigger lock function: suitable for temperature monitoring processes.

- Scheduled measurement: suitable for processes requiring long-term temperature monitoring.

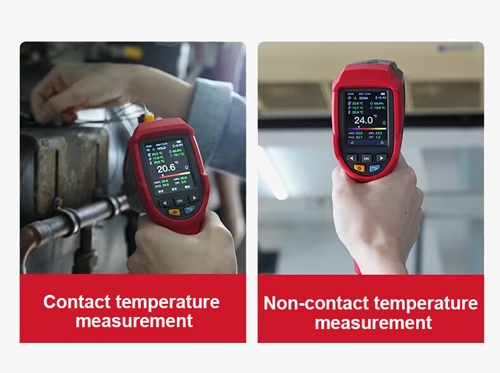

Two Measurement Modes Available for Selection

- A combination of contact temperature measurement and non-contact infrared temperature measurement.

- Storage and review of 999 data sets, with data output supporting PDF and CSV formats.

- High-precision display of ambient temperature, relative humidity, dew point temperature, and wet bulb temperature.

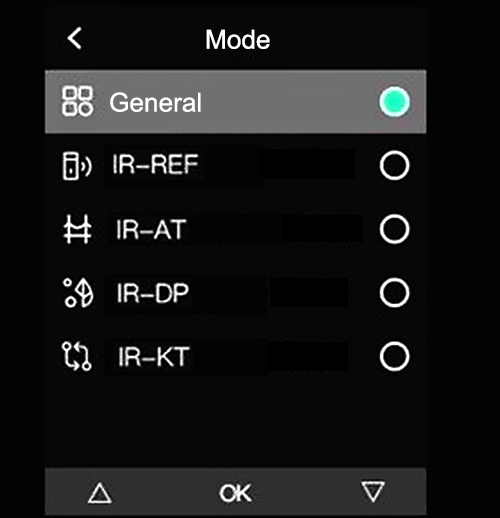

5 Measurement Mode Options

- When "Mode" is displayed in the bottom right of the screen in the HOLD interface, briefly press the right button to enter the mode interface.

- In the mode interface, briefly press the left or right button to select the desired measurement mode, then press OK to confirm.

Applications

2 in 1 no touch high temperature infrared thermometer is widely used in distribution inspections, HVAC maintenance, transportation equipment inspection, equipment repair, and automotive troubleshooting. By providing real-time temperature feedback, it helps determine whether the target is functioning properly. This non-contact detection method is safe and efficient, making it ideal for temperature measurement across various industries.

HVAC Maintenance

Traffic Facility Inspection

Equipment Repair

Power Distribution Inspection

| Model | SISCO-ITHM-305A | ||

| Measuring Range | Infrared Temperature Neasurement | -50℃ to 1850℃ (-58℉ to 3362℉) | |

| Ambient Temperature | -10℃ to 50℃ (14℉ to 122℉) | ||

| Relative Humidity | 10%RH to 90%RH | ||

| K Type Thermocouple | -50℃ to 1370℃ (-58℉ to 2498℉) | ||

| Measurement Accuracy | Infrared Temperature Measurement | <0℃: ± (1.0℃+0.1℃/℃) ≥ 0℃: ±1.0℃ or ±0.01×t℃ whichever is greater ≥ 32℉: ±2.0℉ or ±0.01×t℉ whichever is greater | |

| Ambient Temperature | -10℃ to 0℃ (14℉ to 32℉): ±1℃ (±2℉)/0℃ to 40℃ (32℉ to 104℉): ±0.5℃ (±1℉)/40℃ to 50℃ (104℉ to 122℉): ±1℃ (±2℉) | ||

| Relative Humidity | ±5%RH | ||

| K Type Thermocouple | ±(0.005×t+1.5)℃ / ±(0.005×t+3.0)℉ | ||

| D:S(Distance coefficient) | 55:1 (90%energy) | ||

| Emissivity | 0.1~1.0 Custom adjustment, step length 0.01, or select from the built-in common material table | ||

| Spectral response | 8um to 14um | ||

| Infrared Temperature Measurement Repeatability | ±0.005×t℃ (℉) or 1℃ (2℉) Take the larger value | ||

| Display Resolution | 0.1℃ | ||

| Unit | ℃ or ℉ can be set | ||

| Laser Aiming | Single laser beam, output< 1 mW, II Level, wavelength 630 to 670 nm/conform to EN 60825-1: 2014 Laser Safety Standards | ||

| Data Storage | 999 Group | ||

| Data Output Format | PDF, csv | ||

| Data Communication or Charging Interface | Type-C USB | ||

| Battery | Li-ion 3.7V 2600mAh 18650 Rechargeable lithium-ion battery | ||

| Continuous Working Time | Not less than 20 hour (fully charged continuous working time) | ||

| Alarm Function | buzzer | ||

| Trigger Lock Function | √ | ||

| Appointment Measurement Function | √ | ||

| Real Time, Date | √ | ||

| Display Type | 2.4 inch TFT LCD | ||

| Display Resolution | 320*240 Pixel | ||

| Storage Temperature | -20℃ to 60℃ (-4℉ to 140℉) | ||

| Operating Temperature | -10℃ to 50℃ (14℉ to 122℉) | ||

| Working Environment Humidity | <90%RH (non-condensing) | ||

| Temperature Coefficient | ±0.1℃/℃ or ±0.1%/℃ whichever is greater | ||

| Operating Altitude | Does not exceed 2000 rice | ||

| Drop Test | 1m Guaranteed accuracy | ||

| Weight | 375g | ||

| Size | 124mm (L) × 65mm (W) × 205mm (H) | ||

| CE Certification | EN/IEC 61326-1:2013/EN/IEC 60825-1:2014 | ||

| Standard | manual, USBData cable, K Thermocouple probe (bead type) | ||

| K Thermocouple Probe (bead type): | |||

| Measuring Range | -40°C to 260°C (-40°F to 500°F) | ||

| Accuracy | 0.075×t (t To measure temperature) | ||

| Line Length | 1 m (40 in) long KThermocouple cable with standard miniature thermocouple connector and bead-type probe | ||

Details

Packing List

- 1 x infrared thermometer

- 1 x Type-C data cable

- 1 x K-type thermocouple probe (bead type)

- 1 x Toolbox

- 1 x User manual

- 1 x Certificate of conformity

- 1 x Warranty card

Q1: What are some applications of infrared thermometer in industry?

A1: Infrared thermometers find numerous applications across various industries due to their non-contact nature, speed, and accuracy. Some common industrial applications include: manufacturing, HVAC(Heating, Ventilation, and Air Conditioning), electrical maintenance, food processing, metallurgy, automotive, building inspection, firefighting etc.

Q2: How do you store an infrared thermometer?

A2: When storing your infrared thermometer, choose a clean, dry spot away from extreme temperatures. Keep it protected in its case to prevent dust buildup and damage. Regularly check for signs of wear or damage to maintain its accuracy.

Q3: How far away should you hold an infrared thermometer?

A3: The distance at which you should hold an infrared thermometer depends on its spot ratio, which is the ratio of the distance from the thermometer to the object being measured to the diameter of the measurement area. Typically, the manufacturer specifies the spot ratio for the thermometer. As a general guideline, hold the thermometer at a distance that ensures the measurement spot covers the entire target area, ensuring accurate readings.

Tips: How does a infrared thermometer work?

A 2-in-1 infrared thermometer combines infrared and K-type thermocouple probe measurement modes, offering versatility for different types of temperature readings. Here's how each mode works and how they are integrated into a single device:

Infrared Thermometer Mode

- Emitted Infrared Radiation: Objects emit infrared radiation based on their temperature.

- Detection: The infrared thermometer has a lens that focuses this radiation onto a sensor, typically a thermopile or pyroelectric detector.

- Conversion to Electrical Signal: The sensor converts the infrared radiation into an electrical signal, where the intensity of the radiation (proportional to the object's temperature) determines the strength of the signal.

- Signal Processing: The electrical signal is processed and converted into a temperature reading. Algorithms account for factors like emissivity to ensure accuracy.

Display: The temperature reading is displayed on the device’s screen.

K-Type Thermocouple Probe Mode

- Temperature Exposure: The junction of the K-type thermocouple is placed in contact with the object whose temperature is to be measured.

- Voltage Generation: A thermoelectric voltage is generated at the junction due to the temperature difference between the hot junction (contact point) and the cold junction (reference point).

- Signal Transmission: This voltage is transmitted through the thermocouple wires to the measuring device.

- Temperature Calculation: The measuring device interprets this voltage and converts it into a temperature reading using predefined calibration tables specific to the K-type thermocouple.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.