SISCO cheap price 1/2 inch digital torque meter offers a measurement range from 0.9 to 30 Nm. Ideal for various industrial and maintenance applications, it helps users complete high-precision torque tasks effortlessly, ensuring optimal performance of equipment and components.

Digital Torque Meter Features

- Automatic shutdown. Micro-controller chip for accurate data measurement.

- Three modes. Pre/ Peak/ Track mode.

- Unit switching. lbf.in/ lbf.ft/ Kgf.cm/ N.m.

Digital Torque Meter Features

- Easy disassembly. Easy to dismantle and assemble for easy operation.

- Backlighting. Multi-key intelligent operation.

- Give an alarm. The pre-torque value reached the buzzer alarm sounds.

Applications

SISCO torque meter is widely used in the automotive industry, industrial equipment, aerospace, renewable energy, research and development, medical devices, and robotics. It measures torque in rotating systems to evaluate and optimize the performance of engines and transmissions, ensure proper tightening of bolts and screws on assembly lines, and monitor machinery health.

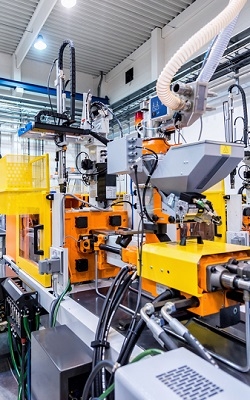

Industrial Equipment

Medical Devices

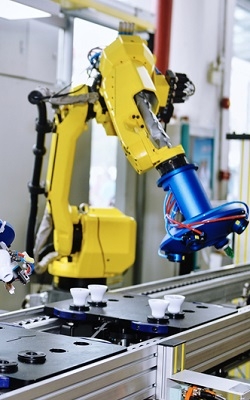

Robotics

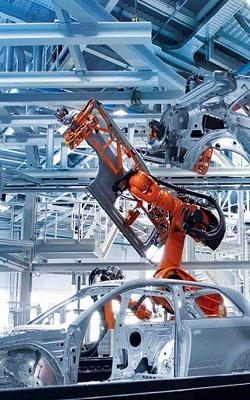

Automotive Industry

| Model | SISCO-TM-FAC30 |

| Accuracy | 2% in the forward direction, 2.5% in the reverse direction |

| Mode | Real-time/Peak/Preset |

| In/Out adapter | 1/2(12.5mm) |

| Torque range | 0.9-30 (Nm) |

| 9.1-306 (kg cm) | |

| 7.9-265.3 (lb in) | |

| 0.66-22.11 (lb ft) | |

| Graduated value | 0.01N.m |

| 0.1Kgf.cm | |

| 0.1lbf.in | |

| 0.01lbf.ft |

Details

Q1: What is a torque meter?

A1: The torque meter is a device used to measure the torque or rotational force, applied to a rotating system, providing critical data for evaluating and optimizing the performance and health of engines, transmissions, machinery, and other mechanical components across various industries.

Q2: What is a torque meter used for?

A2: The torque meter, also known as a torque sensor or transducer, is used to measure the torque (rotational force) in various applications, including evaluating and optimizing engine and transmission performance in the automotive industry, ensuring proper tightening of bolts and screws in industrial assembly lines, monitoring machinery health, testing aerospace components, optimizing wind turbine performance, conducting research and development of new products and materials, and measuring and optimizing the torque in medical tools and robotic joints for safe and reliable operation.

Q3: What is the difference between a torque meter and a torque wrench?

A3: A torque meter is a device that measures the torque (rotational force) applied to a rotating system, often used for monitoring and testing purposes, whereas a torque wrench is a tool used to apply a specific amount of torque to a fastener, such as a bolt or a nut, ensuring it is tightened to the correct specification.

Tips: How does a digital torque meter work?

A digital torque meter works by using sensors to measure the torque applied to a rotating system and then converting that measurement into a digital signal. The key components of a digital torque meter include a strain gauge, a signal conditioner, and a digital display.

- Strain Gauge: The strain gauge is typically bonded to a rotating shaft. When torque is applied to the shaft, it causes a deformation (strain) in the strain gauge. This strain changes the electrical resistance of the gauge, which can be measured.

- Signal Conditioner: The changes in resistance are converted into an electrical signal by the signal conditioner. This signal is then amplified and processed to ensure it accurately reflects the amount of torque being applied.

- Digital Display: The processed signal is converted into a digital format and displayed on a screen. The display shows the torque value in real-time, allowing for precise monitoring and control.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.