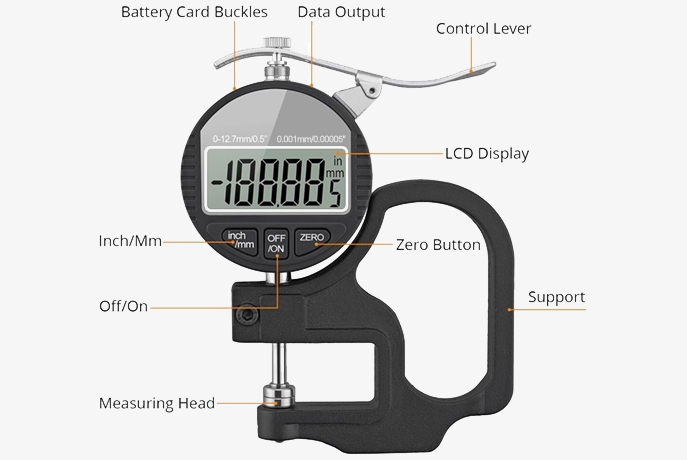

SISCO digital thickness meter is compatible with flat measuring port and alloy measuring face, and it is widely used in soft materials thickness measurement.

High-Efficiency Thickness Measuring Instrument with Advanced Technology

- Equipped with imported measurement chip, the speed is as fast as 3 meters/second, making measurement easier.

- Units convert between Metric and Inch, eliminating the need for additional unit conversions and saving measurement time.

Multifunctional Compact Digital Thickness Gauge Meter

- Large LCD display bids farewell to "estimated reading", digital direct reading, clearer display.

- Equipped with a zero-setting button, allowing for convenient measurement adjustments.

- Finely ground alloy steel quenched measuring surface ensures that the measuring surface reaches the level of the gap when closed, ensuring accuracy.

Auto Shutdown Thickness Gauge with Long-Lasting Battery

- Automatic shutdown function: After 180 seconds of inactivity.

- Low energy consumption and long-lasting durability, equipped with 5 original batteries.

- When not in use for a long time, the battery should be removed to ensure longer use.

Applications

SISCO flat-head digital thickness tester is used for measuring soft materials such as leather, paper, and films. It leverages advanced digital technology to ensure precise and reliable thickness measurements. The flat-head design is ideal for soft and flexible materials, as it minimizes the risk of surface damage during the measuring process. Additionally, this gauge is known for its user-friendly interface and portability, making it suitable for a wide range of applications, including manufacturing, quality control, and research.

Fiber Thickness

Veneer Thickness

Leather Thickness

Paper Thickness

| Model | SISCO-DTG-201 |

| Measuring Range | 0-12.7mm/0.5 inch |

| Accuracy | 0.001mm |

| Tolerance | ±0.005mm |

| Supply Voltage | 1.5V |

| Dimensions | 130mm*100mm*25mm |

Dimensions (mm)

Details

Packing List

- 1 x Digital thickness gauge

- 1 x Box

- 5 x CR2032 battery

- 1 x User manual

- 1 x Certificate

Q1: What materials can be measured with a digital thickness gauge?

A1: A digital thickness gauge can measure a variety of materials, including metals (such as steel, aluminum, and copper sheets and plates), plastics (various types of plastic films and sheets), glass (glass panels and sheets), rubber (rubber sheets and components), wood (wood panels and veneers), paper and cardboard (paper sheets and cardboard), composites (various composite materials used in aerospace, automotive, and other industries), ceramics (ceramic tiles and components), coatings (paint, varnish, and other surface coatings applied to substrates), and fabrics and textiles (fabric and textile sheets, especially in quality control and manufacturing processes). The versatility of a digital thickness gauge depends on its specific design, sensor type, and measurement range.

Q2: How to maintain and care for a digital thickness gauge?

A2: To maintain and care for a digital thickness gauge, regularly clean the device by wiping the probe and sensors with a soft, dry cloth to remove dust and debris. Store the gauge in its protective case to prevent physical damage and keep it in a dry, temperature-controlled environment to avoid extreme conditions. Perform regular calibrations as recommended by the manufacturer, using appropriate calibration standards to ensure accuracy. Replace batteries with the recommended type and remove them if the gauge will not be used for an extended period to prevent leakage. Handle the gauge gently to avoid drops and excessive force, and avoid exposing it to moisture. Regularly inspect the gauge for any signs of wear or damage, and address any issues promptly to ensure its reliability and performance.

Q3: Do digital thickness testers need calibration?

A3: A digital thickness gauge requires calibration to ensure its accuracy and reliability. Regular calibration is essential to provide precise measurement results, which are crucial in applications such as quality control, manufacturing, and material inspection. Calibration also helps maintain measurement consistency and prevent errors and discrepancies in repeated measurements. It is important to follow the manufacturer's calibration guidelines, using appropriate calibration standards or blocks, which are typically provided by the manufacturer and made from materials with known thicknesses. Calibration should be performed across the gauge’s measurement range to ensure accuracy at various thickness levels.

Additionally, documenting the calibration date, standards used, and any adjustments made is crucial for quality control and compliance. Calibration frequency depends on the device’s usage and environmental conditions but is generally recommended before daily use, monthly, or annually, or after major events such as dropping the device, significant temperature changes, or repairs. By following these practices, you can detect and prevent performance issues, ensuring that the digital thickness gauge remains accurate and reliable throughout its use.

Tips: How does a digital thickness meter work?

A digital thickness gauge measures the thickness of materials with precision using electronic sensors and displays the results on a digital screen. The operation involves three main steps:

- Measurement Principle: The gauge uses capacitive, ultrasonic, or mechanical sensors to detect material thickness. Capacitive sensors measure thickness by detecting changes in capacitance between two electrodes; ultrasonic sensors calculate thickness by timing how long high-frequency sound waves take to travel through the material; mechanical sensors measure thickness by contacting the material and converting the mechanical movement into electronic signals.

- Signal Processing: The sensor converts the measured data into an electrical signal, which is processed by the gauge’s internal electronics. This signal is then converted into a digital thickness reading, displayed on the screen in units such as millimeters or inches.

- Additional Features: Many digital thickness gauges offer calibration functions, allowing for adjustments using known thickness standards to ensure accuracy. They may also support data storage and unit conversion for ease of use and record-keeping.

These steps enable the digital thickness gauge to provide accurate and clear measurements, making it a valuable tool in quality control, manufacturing, and material testing.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.