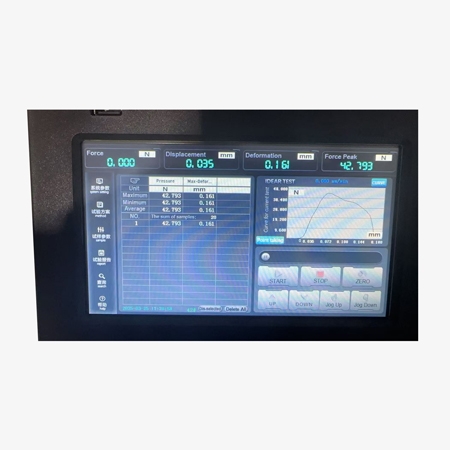

The tensile strength apparatus is equipped with an intuitive touch screen to simplify the test process. It can collect and display force, displacement, and other data in real time to ensure the accuracy of the test results.

A Variety of Test Types can be Selected

- The main function of the fabric tensile strength tester is to test materials in tension, compression, bending, etc.

- The textile tensile testing machine is equipped with a printer, which can directly print the test results to avoid errors in data transfer.

- The electronic tensile tester uses a color touch LCD screen, supports graphical display, and has more flexible data processing methods.

Durable and can be Tested in Many Ways

- The bracket is made of high-strength steel and can withstand greater pressure without deformation.

- The body of the fabric tensile testeruniversal testing machine is a cold plate painted, which is not easy to fall off and is easy to clean.

- The universal testing machine has multiple safety protection devices, such as overload protection, short circuit protection, and overvoltage protection, which make it safer to use

Applications

Tensile testing machine is a commonly used material testing equipment, which is used to evaluate the mechanical properties of materials under tension, test their tensile strength, yield strength rate and other mechanical properties, and evaluate the performance of raw materials and finished products. A tensile strength tester can be used in many scenarios, such as new material research and development, metal processing, plastic molding, experiments etc.

Electronic Appliances

Industrial Plastics

Laboratory

Auto Parts

| Model | SISCO-TT-HN50KG |

| Load Cell | 1/5/10/20/50/100/200/500kg |

| Force Resolution | 1/1000000 |

| Force Accuracy | ≤0.5% |

| Force Magnification | Stepless speed regulation |

| Displacement Resolution | 1/1000 |

| Displacement Confirmation | ≤0.3% (Strength Unit Kg, N.KN, g.lb, Displacement Units mm.cm.inch) |

| Large Deformation Extensometer Accuracy | ±1mm |

| Speed Range | 0.001mm/min~500mm/min |

| Travel Space | 450mm with holder |

| Test Width | 12mm |

| Power Supply | 220V 52Hz |

| Machine Dimensions | 450mm×350mm×1100mm |

| Machine Weight | 50kg |

Q1: Does the Test Speed of the Tensile Tester Affect the Test Results?

A1: The test speed of the tensile tester has a significant effect on the test results. Test speed refers to the rate at which the specimen is stretched during the tensile test, usually expressed in millimeters per minute (mm/min) or strain rate (such as percentage change per second).

Q2: How to Choose the Appropriate Test Speed Based on Material Properties?

A2: When choosing the appropriate test speed for material testing, multiple factors need to be considered, including the material's mechanical properties, strain rate sensitivity, test standards, and experimental purpose.

Q3: How to Use a Tensile Tester?

A3: First, prepare the machine to ensure that the machine is in good working condition and check whether all parts are intact, Install the specimen correctly in the fixture of the tester. Set the initial height of the pendulum according to the test standard to ensure that the pendulum has enough energy for the test when it is released. Release the pendulum and let it fall freely and hit the specimen. After the pendulum hits the specimen, record the final position of the pendulum or record the data through the automatic measurement system of the testing machine.

Tips: What are the Key Points of the Maintenance and Care of the Tensile Testing Machine?

The maintenance and care of the tensile testing machine is essential to ensure its test accuracy, extend its service life, and ensure safe operation. The control system maintenance requires regular inspection of whether the connection wires on the rear panel of the controller are in good contact. If they are loose, tighten them in time. The fixture is the place that directly contacts the test sample, and its cleanliness and clamping force should be maintained. According to the use of the machine and the service life of the oil, regularly replace the oil suction filter and filter element, replace the hydraulic oil, and apply anti-rust oil to the fixture.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.