A U tube manometer is a simple device, it consists of a transparent U-shaped tube. U type manometer is valued for their simplicity, accuracy, and reliability in many applications. It has no moving parts, requires no calibration, and is ideal for laboratory or educational use. The U tube manometer is a classic and effective tool in fluid mechanics for visualizing and measuring pressure differences in a straightforward and intuitive manner.

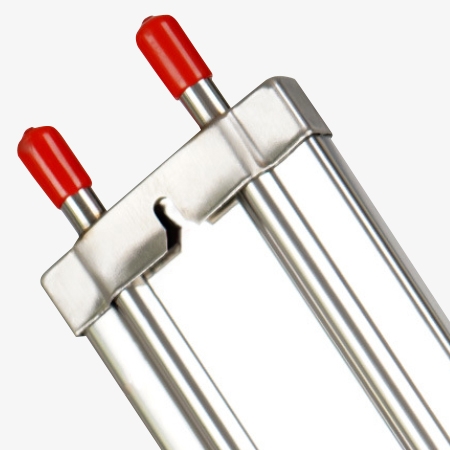

U Tube Manometer Adopts Stainless Steel Material

- Corrosion Resistance. Stainless steel is highly resistant to corrosion, making it ideal for use in environments where the manometer may be exposed to moisture or other corrosive substances.

- Low Maintenance. Due to its resistance to corrosion and staining, stainless steel requires minimal maintenance, which is beneficial in ensuring that the manometer remains accurate reading and without frequent repairs or replacements.

- Precision and Accuracy. The rigidity of stainless steel ensures that the U shaped manometer remains stable, contributing to accurate pressure measurements, especially when compared to materials that may expand, contract, or deform under pressure changes.

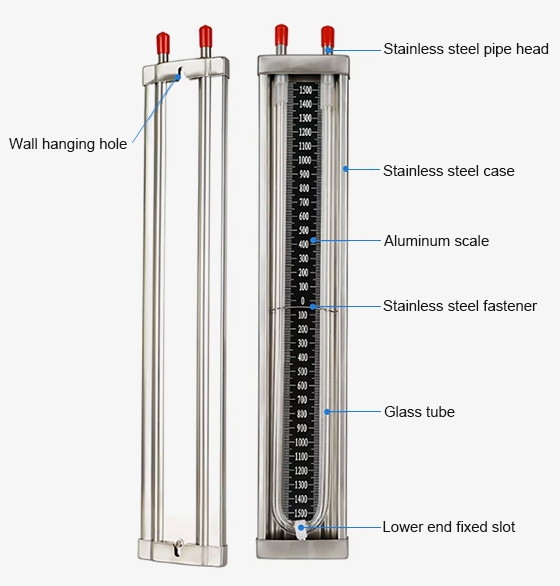

Wall Hanging Hole of U Shaped Manometer

- Space Efficiency. The hole allows the manometer to be mounted on a wall, saving valuable workspace. This is especially useful in labs or industrial settings where space is limited.

- Stability. Hanging the manometer from a wall can provide better stability, reducing the risk of it tipping over or being accidentally knocked down. This ensures more accurate and consistent readings.

- Convenience. When the U tube manometer is wall-mounted, it can be positioned at an optimal height for easy reading, making it more user-friendly.

Applications

In practical applications, U tube manometers are often found in ventilation systems to monitor airflow and ensure proper system performance. They are also commonly used in laboratories for educational demonstrations and experiments involving fluid dynamics. Their ability to measure small pressure differences with high precision makes them particularly useful in situations where sensitivity is crucial.

Hydraulic System

Gas Pressure Measurement

Medical Research

Heating System

| Model | SISCO-M-UTM |

| Measuring range | ±500 Pa/ ±1000 Pa/ ±1500 Pa/ ±2000 Pa/ ±2500 Pa/ ±3000 Pa/; 0-1000 Pa/ 0-2000 Pa/ 0-3000 Pa/ 0-4000 Pa/ 0-5000 Pa/ 0-6000 Pa |

| Length | 10/ 20/ 30/ 40/ 50/ 60 cm |

| Material | stainless steel |

| Weight | about 5-8kg |

Structure:

Q1: What are the advantages of using U tube manometer?

A1: One of its main benefits is its simplicity, constructed with transparent tubing, it requires no complex electronics or power supply, making it cost-effective and easy to maintain. Its accuracy is another key advantage, especially in low-pressure systems, as U shaped manometer provides direct, visual readings based on fluid displacement.

Q2: How to maintain U tube manometer?

A2: To maintain a U tube manometer, regular inspection and cleaning are essential. Ensure the tubes are free from dust, debris, or blockages that may affect readings. Use a suitable cleaning solution to remove any deposits inside the tubes, and rinse thoroughly with distilled water. Keep the manometer in a vertical position during use to ensure precise measurements. Store it in a clean, dry place to avoid contamination or corrosion. Routine care extends its life and ensures reliable performance in pressure measurements.

Q3: Why must the U-tube be transparent?

A3: A U-tube must be transparent to allow clear observation of the fluid levels on both sides. In experiments involving pressure measurements or fluid dynamics, such as with a manometer, it's essential to see the height difference between the liquid columns. This height difference directly corresponds to the pressure being measured, so accurate readings depend on visibility. Transparency ensures precise alignment with a scale for measurements and helps detect air bubbles, impurities, or changes in fluid behavior that might affect results. Without transparency, readings would rely on guesswork, reducing accuracy and reliability.

Tips: What are the limitations of U tube manometer?

A U tube manometer, while simple and effective for measuring pressure differences, has several limitations. Firstly, it is limited in terms of pressure range; it is only suitable for measuring relatively low pressures due to its reliance on the height of a liquid column. The liquid used, typically mercury or water, must be immiscible and non-volatile, but this can introduce risks (e.g., mercury's toxicity). Its accuracy can also be affected by factors like temperature fluctuations, which can change the density of the liquid, and the orientation of the manometer.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.