High quality handheld refrigerant gas leak detector has 3 selectable sensitivity levels of High/Medium/Low, the maximum sensitivity up to 0.14oz/yr. The leak detector designed with a microprocessor control with advanced digital signal processing. Semiconductor sensor, automatic zero and background compensation. Its flexible gooseneck probe ensures easy access to confined or hard-to-reach areas.

Refrigerant Gas Leak Detector Features

- Use semiconductor sensors with extremely high sensitivity to halogen.

- Use microprocessor signal processing control.

- Multi-color segment display.

- High or low sensitivity selection.

- Low battery indication.

- Semiconductor gas sensor.

- Halogen detection of R-134a, R-410A, R-407C, R22.

- Use 40 cm coils for flexible detection.

- The surrounding environment can be reset as background to facilitate detection.

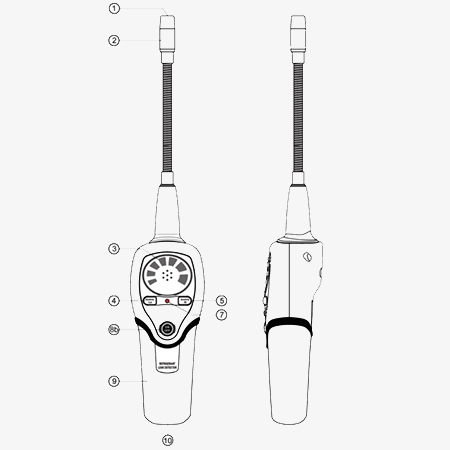

Structure of the Refrigerant Leak Detector

- Sensor

- Sensor cover

- LED leakage indicator

- Low sensitivity button

- High sensitivity button

- Ambient background reset button

- Low battery indicator

- Power switch & ambient background reset button

- Battery cover

- Battery cover screw

Applications

SISCO refrigerant leak detectors are essential tools for identifying and locating leaks in refrigeration and air conditioning systems. They are widely used in HVAC maintenance, automotive air conditioning repair, and cold storage facility inspections to ensure system efficiency, prevent environmental harm, and comply with safety regulations. These detectors help professionals quickly pinpoint leaks in systems using refrigerants like CFCs, HCFCs, and HFCs, ensuring timely repairs and reducing downtime.

Automotive AC Repair

Industrial Refrigeration

Storage Facility Inspections

HVAC Maintenance

| Model | SISCO-RLD-380 |

| Measurement Type | R-134a, R-410A, R-407C, R22, etc. |

| Sensitivity | R22, R-134a: 6g/year (high), 30g/year (low) R-404A, R-407C, 410A: 8g/year (high), 40g/year (low) |

| Alarm Method | Buzzer, three-color LED indicator |

| Hose Length | About 40cm |

| Automatic Shutdown | About ten minutes |

| Warm-up Time | About 90 seconds |

| Operating Temperature | 0~40℃ |

| Operating Humidity | <80% RH |

| Storage Temperature | -10~60℃ |

| Storage Humidity | <70% RH |

| Altitude | Less than 2000 meters |

| Dimensions | 173*66*56mm |

| Weight | 400g |

Q1: What is a refrigerant leak detector?

A1: A refrigerant leak detector is a specialized tool used to identify and locate leaks in systems that use refrigerants, such as air conditioning units, refrigerators, freezers, and HVAC systems. These devices are essential for ensuring the efficiency and longevity of cooling systems by detecting refrigerant gas leaks that can lead to reduced performance, increased energy consumption, and costly damage over time.

Q2: What types of refrigerants can the refrigerant leak detector detect?

A2: Refrigerant leak detectors can detect a wide range of refrigerants used in air conditioning and refrigeration systems, including:

- CFCs (Chlorofluorocarbons): Older refrigerants like R-12, now phased out.

- HCFCs (Hydrochlorofluorocarbons): Such as R-22, still in use but being replaced.

- HFCs (Hydrofluorocarbons): Common modern refrigerants like R-134a, R-410A.

- HFOs (Hydrofluoroolefins): New, eco-friendly refrigerants like R-1234yf.

- Natural Refrigerants: Including ammonia (R-717), carbon dioxide (R-744), and hydrocarbons like propane (R-290).

- Blends: Mixtures like R-407C or R-507.

Q3: What are the different types of refrigerant leak detectors?

A3: There are several types of refrigerant leak detectors, each using different technologies to detect refrigerant leaks. The main types are:

- Halogen Leak Detectors: Detect halogen-based refrigerants (like R-22, R-410A). Simple and commonly used.

- Heated Diode Leak Detectors: Highly sensitive and fast at detecting halogen refrigerants, good for small leaks.

- Infrared (IR) Leak Detectors: Detect a wide range of refrigerants, including eco-friendly ones. Accurate and reliable.

- Ultrasonic Leak Detectors: Detect leaks by picking up sound waves from escaping gas. Useful in noisy environments.

- Electronic Leak Detectors: Use different sensors to detect refrigerants. Lightweight and portable.

- Combustible Gas Detectors: Detect flammable refrigerants like propane or ammonia.

Tips: Tips for using refrigerant gas leak detector

1. The halogen leak detector is not designed to be anti-explosive. Please do not use it in an environment with volatile and explosive gases.

2. Some environmental conditions may cause measurement errors:

- Pollutant places.

- Large temperature changes.

- High wind speed places.

- Organic solvents and fuel gases will cause abnormal responses from the sensor. Try to avoid environments involving such substances.

- There are too many halogen gases in the environment.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.