The handheld spectrometer mainly uses XRF technology to quickly and accurately analyze the content of multiple elements in the sample within a few seconds to tens of seconds, and can quickly perform non-destructive detection on-site, without radiation risk, and with higher safety.

Powerful Functions

- Excellent performance, one-button operation, high detection accuracy (close to laboratory-level analysis level), and intuitive display of alloy grade and element percentage content (elements can reach three decimal places) and PPM content in a few seconds. Non-professional technicians can also easily master it.

- To realize the transmission of data between the handheld spectrometer and the mobile phone, download the mobile application APP, connect to the mobile phone hotspot, click to generate a report on the instrument screen saver interface, and then open the APP to select the corresponding report download to realize data transmission.

- The hand held spectrometer has a built-in new net intensity fitting algorithm, which optimizes the spectral analysis process so that XRF has an extremely low detection limit comparable to large laboratory equipment.

Quality Assurance

- The portable spectrometer uses a low-power (4W) X-ray tube, a protective screen, and a micro-collimator to prevent the escape of X-rays, reduce the radiation, and ensure that no measurable radiation is detected during the operation of the instrument.

- The spectroscopy instrument is small in size, light in weight, more convenient to carry, and is equipped with an MSBUS bus monitoring battery.

- The spectrometer uses an industrial resistive touch screen with excellent backlight performance. The spectrometer instrument can read clearly in strong light or dark environments outdoors, eliminating the danger of removing gloves in special outdoor environments.

Applications

Spectrometers have a wide range of applications. They can measure the intensity of light in different wavelength ranges, providing information about the composition and properties of materials. In materials science, they analyze composition and structure, and detect impurities and defects in materials. In semiconductor manufacturing, they monitor the growth and processing of semiconductor materials and control the quality and performance of materials. In geological monitoring, they analyze rock samples to determine the presence of oil and gas. In scientific research and education, they can be used to study the microstructure of metal materials and analyze the structure and composition of metal compounds.

Geological Monitoring

Materials Science

Semiconductor

Scientific Research

| Model | SISCO-PS-AGSW3000 |

| Excitation Source | Four Optional: Au, Ag, W, Pd |

| Voltage, Current and Power | 500KV, 100MA, 4W |

| Filter | Six types, can be automatically adjusted according to different objects |

| Detector | High-performance resolution Si-Pin X detector |

| Detector Cooling Temperature | Peltier effect semiconductor cooling, cooling temperature -35℃ |

| Standard Film | External 316 standard cap, with test window protection function |

| Resolution | <180ev |

| Power Supply | 8 hours/2 lithium batteries and AC power supply |

| Processor | Intel 400MHz StrongArm processor |

| Operating System | Mobile Windows CE system |

| Compatibility | Bluetooth |

| Software Standard Mode | Alloy |

| Data Processing | 8G data storage card: ≥40000 sets of data and spectra |

| Data Analysis | Multiple analysis modes |

| Data Display | Focus on ppm and percentage (%) display, spectrum or peak intensity (count rate) or user-defined units |

| Data Transmission | RS232 serial cable, Bluetooth, EXCEL output |

| Display Screen | Color high-resolution 3.5-inch TFT industrial touch screen |

| Safe Operation | Automatically shut down within 3 seconds after judging that there is no sample in front of the test window |

| Analytical Elements | Can analyze all elements from Ti to U |

| Test Environment Conditions | Temperature -20~50℃, humidity <80%RH |

| Dimensions | 30cm×90cm×22cm |

| Weight | 1.5kg |

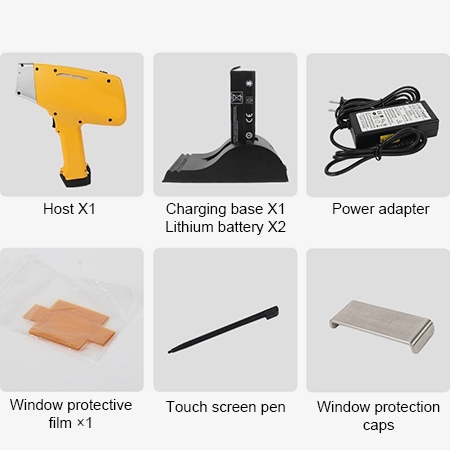

Structure Diagram

- Detection Indicator Light

- Radiator

- One-Touch Power Button

- Interface Touch Screen

- Spectrum Browsing Button

- Battery Protective Cover

Packaging List

A1: What is the difference between a UV-Visible spectrophotometer and a visible spectrophotometer?

Q1: The difference between UV-Visible spectrophotometer and visible spectrophotometer is that the measurement wavelength range is different, UV generally uses a hydrogen lamp, the measurement wavelength range is of 180 ~ 350NM, visible generally uses a tungsten lamp, and the measurement wavelength range of 320 ~ 1000NM. The so-called UV-Visible spectrophotometer also means that this instrument can change the light source, can determine the absorption peak in the UV and visible part of the compound.

A2: What is the wavelength range of the UV-Visible spectrophotometer?

Q2: Ultraviolet-visible (UV-Vis) spectrophotometers use a light source that illuminates the sample with light in the UV to visible wavelength range (typically 190 to 900 nm). UV-Vis-NIR spectrophotometers extend the wavelength range to the near-infrared (NIR) (800 to 3200 nm).

A3: What is the principle of operation of a spectrophotometer?

Q3: The basic principle of the spectrophotometer is that the substances in solution are excited by light irradiation, resulting in the effect of light absorption, the absorption of light by substances is selective, a variety of different substances have their own absorption spectrum, so when a monochromatic light through the solution, its energy will be absorbed and diminished, the degree of light energy diminution and the concentration of substances have a certain proportional relationship, that is, in line with the colorimetric principle - -Biel's law.

Tips: Factors Affecting Spectrometer Detection

There are many factors that affect spectrometer detection. In order to obtain accurate and reliable spectral data, comprehensive analysis is required. The wavelength range determines the detectable spectral range, the resolution affects the ability to distinguish spectral details, and the sensitivity determines the ability to detect low-concentration samples. In addition, the light source intensity and stability of the instrument will also affect the accuracy and repeatability of the detection. The operator needs to be familiar with the operating procedures and parameter settings of the spectrometer, and be able to correctly process and analyze the detection data.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.