The digital dew point meter uses a 316L stainless steel probe housing with an IP66 waterproof rating, which can effectively protect the sensor. One machine has multiple uses and can measure dew point, wet bulb, temperature, and humidity. It can easily cope with on-site measurement, sampling, and calibration needs on various occasions.

Note: When using a dew point meter, please equip a dedicated gas sampling kit (including a thread adapter and gas collection chamber), which can effectively improve detection accuracy.

Powerful Functions

- Adopt high-precision temperature and humidity sensor probe, stable and accurate readings, ±0.1C/±1.5%RH high precision.

- Reserved iot function, can connect to Bluetooth, real-time monitoring data.

- Direct plug-in data transmission, can be connected to the computer USB interface without cable, safe and fast transmission to the computer.

- Can store 32000~64000 data storage, and 99 sets of data can be directly called.

Easy to Operate

- The dew point meter can be optionally equipped with a tool kit and a replaceable T900 probe. The default probe is a 316L stainless steel temperature and humidity probe, which is waterproof and dustproof, has good air permeability and a stable structure. 316L stainless steel temperature and humidity probe, waterproof and dustproof, good air permeability, stable structure.

- The large high-definition backlit LCD display is clear and easy to read, and data can be read quickly in the sun and at night.

- Silicone micro-switch level case, good feel, and fast response.

Applications

In the agricultural field, dew point meters are mainly used to monitor humidity in greenhouses, providing a suitable environment for the growth of crops, and thereby improving the yield and quality of agricultural products. In industrial production, dew point thermometers are essential for monitoring and controlling humidity in the air. In environmental monitoring, handheld dew point meters can be used to monitor changes in humidity in the atmosphere and provide important data for climate change research. With the development of sensor technology and signal processing technology, the measurement accuracy of dew point meters will continue to improve and meet more stringent measurement requirements.

Chemical

Electronic Component

Laboratory

Greenhouse

| Model | SISCO-DPM-HG970 | |

| Environment Temperature | Measurement Range | -30~80℃ (probe only) |

| Accuracy | ±0.1℃ (@20℃) | |

| Resolution | 0.01°C/℉ | |

| Sampling Frequency | 1 time per second | |

| Relative Humidity | Measurement Range | 0~100%RH |

| Accuracy | ±1.5%RH (20~60%RH, @20℃) | |

| Resolution | 0.1%RH | |

| Response Time | Less 10s (90% 25℃, wind speed 1m/s) | |

| Dew Point | Temperature Range | -30~80 ℃ (For accuracy, see the figure "Dew Point Accuracy Table") |

| Wet Bulb | Temperature Range | -20~60℃ (-4~140℉) |

| Other | Power | A standard 9V 6LR61 or 6F22 battery |

| Battery Life | About 300 hours (use 6LR61 9V alkaline battery) | |

| Operating Environment | 0~40℃ (32~104℉), <80%RH Non - Condensing | |

| Storage Environment | -10~60℃ (14~140℉), <80%RH Non - Condensing | |

| Weight | 1.5kg | |

| Size | 215mm×58mm×33mm | |

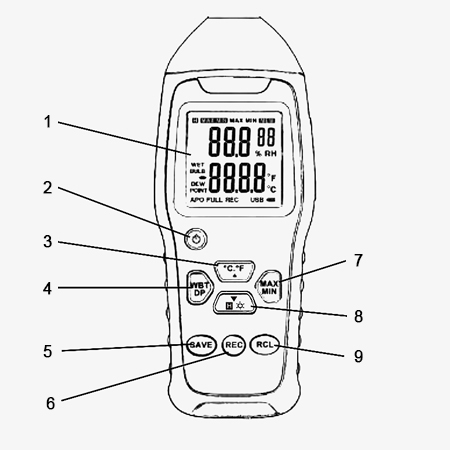

Structure Diagram

- Display Screen

- Power Button

- °C/℉ Nnit Selector Button

- Dew Point Temperature/Wet Bulb Temperature/Ambient Temperature Selection Button

- Data Store

- Record Button

- MAX/MIN Button

- Data Hold Button

- Data Invocation

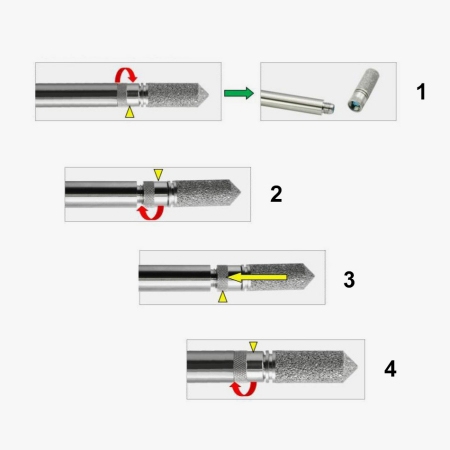

Probe Replacement Diagram

- Unscrew the connection nut clockwise and disassemble the old probe.

- Connect the joints and slowly rotate the joints to find the connection holes. After the holes are connected, turn the connection nut counterclockwise. After taking 2-3 turns, gently push the probe toward the long rod to the connection nut, and then continue to tighten the nut until it is tightened.

- After the holes are connected, turn the connection nut counterclockwise. (Make sure the hole position is correct before tightening the nut, otherwise, it is easy to damage the joint)

- After taking 2-3 turns, gently push the probe toward the long rod to the connection nut. Continue to tighten the nut until it is tightened.

Q1: What factors affect the measurement accuracy of the dew point meter?

A1: The accuracy and stability of the dew point meter not only depend on the performance of the instrument itself, but are also affected by environmental conditions, its own factors, and the operator. Understanding these influencing factors is very important for the correct use and maintenance of dew point meters, and for improving measurement accuracy.

- Environmental conditions have a significant impact on the measurement accuracy of a dew point meter. These include factors such as temperature, humidity, and air pressure. The influence of temperature on the dew point meter is mainly reflected in the different saturated water vapor pressures of air at different temperatures, so measurements need to be carried out under constant temperature conditions. Humidity is an important indicator of the moisture content in the air. When the moisture in the air reaches saturation, the humidity reaches 100%. Changes in air pressure also affect moisture status, so constant air pressure conditions need to be maintained during measurements.

- The performance of the instrument itself also has a great impact on measurement accuracy. For example, sensor sensitivity, response time, and stability are all key factors that affect measurement accuracy. In addition, the calibration status of the instrument will also affect the measurement results. Regular calibration is the key to ensuring measurement accuracy.

- The operator's operation method will also affect the measurement results of the dew point meter. For example, during use, severe vibrations and collisions should be avoided to avoid damaging the precision components inside the equipment. During measurement, appropriate gas flow should be controlled to avoid measurement errors caused by excessive flow.

Q2: How often should a dew point meter be calibrated?

A2: As an important humidity measurement device, the calibration cycle of a dew point meter is crucial to ensure the accuracy and reliability of the measurement data. According to the search results, the calibration cycle of a dew point meter varies according to different usage and environmental conditions. Generally, it is recommended that users check the dew point meter every two years, while in some cases (such as when the gas path is severely contaminated), it is recommended to check it every six months. Dew point transmitters should be calibrated once a year. Proper calibration and maintenance can greatly improve the measurement accuracy and stability of the dew point meter, thereby ensuring the quality and safety of related industrial processes.

Q3: How to clean the probe of a dew point meter?

A3: How often the probe of a dew point meter needs to be cleaned depends on a variety of factors, including the environment in which it is used, the frequency of use, the cleanliness of the sample gas, and the specific requirements of the instrument. Here are the steps to clean the probe.

Before you begin cleaning, make sure the device is turned off and disconnected from the power supply. If possible, disassemble easily removable parts.

Use a soft cloth and a mild cleaner (such as diluted detergent) to clean the device housing. Avoid using any corrosive substances that may damage the surface or penetrate into the interior of the device.

The probe is the most critical part of the dew point meter. According to the manufacturer's instructions, some probes may allow for gentle wiping with a soft cloth. If the probe has special cleaning requirements (such as specific cleaning solvents), follow these guidelines.

If the dew point meter is equipped with an air filter, check whether the filter needs to be cleaned or replaced.

After cleaning and drying all parts, reassemble the device and perform a simple functional test to ensure that everything is working properly.

Tips: Analysis of dew point meter calibration steps

The calibration steps of a dew point meter involve multiple stages. The first is preparation. It is necessary to ensure that the instrument is in good working condition, check the battery power, and sensor cleanliness, and prepare standard gas or calibration fluid. Next is zero-point calibration. Place the instrument in a dry environment, record the zero point reading, and then place it in an environment with known humidity for comparison. Then comes the range calibration. Use standard gas or calibration fluid to cover the measurement range of the instrument, record the instrument reading, and compare it with the standard value. Multi-point calibration is to improve the accuracy of the calibration. Select multiple standard gases with different dew point values for calibration. Finally, temperature compensation and long-term stability checks are required to ensure the measurement stability of the instrument in different environments. Proper calibration and maintenance can greatly improve the measurement accuracy and stability of the dew point meter, thereby ensuring the quality and safety of related industrial processes.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.