The nitrogen gas purity meter is an affordable yet high-precision solution for monitoring nitrogen purity in various industrial applications. Built with a compact and lightweight design, the analyzer is easy to install and operate, reducing setup costs and maintenance effort.

Compact & Lightweight Design

- The nitrogen gas purity analyzer is small, lightweight, and easy to install.

- Uses an imported electrochemical sensor for precise and rapid nitrogen purity measurement.

- The nitrogen gas purity analyzer features an intuitive LCD screen for real-time oxygen concentration readings.

- The nitrogen (N2) purity meter is designed with a rational structure, making it easy to use and maintain.

Standard 4-20mA Signal Output

- Allows upper and lower limit settings, ensuring the nitrogen gas purity analyzer maintains gas purity standards.

- The nitrogen purity analyzer includes relay output for external alarms and system automation.

- The nitrogen purity gas analyzer provides a stable analog output, allowing integration into industrial monitoring systems.

- The nitrogen purity tester ensures long-term stability, making it ideal for continuous gas purity monitoring.

Applications

SISCO nitrogen (N2) purity analyzers are widely used in industries such as electronics manufacturing, food packaging, pharmaceuticals, petrochemicals, and laser cutting to ensure high-purity nitrogen for oxidation prevention, quality control, and safety.

Petroleum

Food

Pharmaceutical

Electronic

| Model | SISCO-PA-RLZ100 |

| Display Mode | LCD |

| Measurement Range | 75.000%~99.999% |

| Stability | Zero Point Drift: ±1% FS; Span Drift: ±1% FS |

| Repeatability | ±0.5% FS |

| Sample Gas Flow Rate | 400±50 ml/min |

| Response Time | τ90 ≤ 15 seconds |

| Sample Gas Pressure | 0.05 MPa≤Inlet Pressure≤0.25 MPa |

| Analog Output | 4~20 mA standard output signal, with a load resistance of less than 500 ohms (0 - 10 V is optional) |

| Digital Output | Standard RS485, enabling two-way communication with a computer |

| Contact Output | Dual relay output, 220 VAC, 10 A or 24 VDC, 2 A |

| Working Power Supply | 220V/110V ± 10%, 50Hz/60Hz |

| Working Temperature | -5°C~+45°C |

| Working Humidity | ≤ 90% RH |

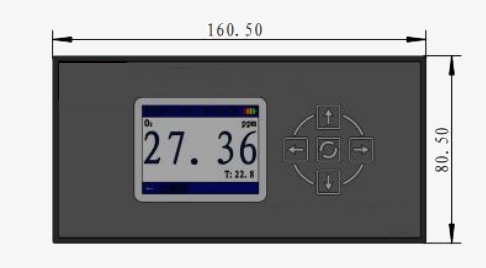

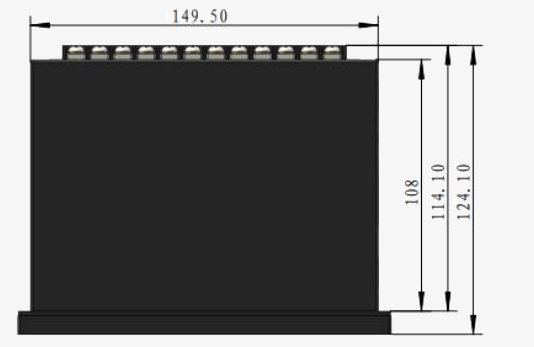

| Overall Dimensions | 160.5mm (width) × 80.5mm (height) × 124.1mm (depth) |

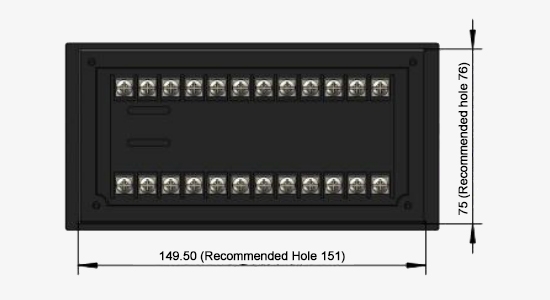

| Cutout Dimensions | 151mm (width) × 76mm (height) |

| Weight | 600g |

| Service Life | 6 years (under normal operating conditions with standardized operation) |

| Gas Path Interface | Φ6 flexible hose (can be customized according to customer requirements) |

Dimension (Unit: mm)

Q1: What is the measurement range of the nitrogen purity analyzer?

A1: The nitrogen purity analyzer is designed to measure nitrogen purity within a typical range of 75.00% to 99.999%, depending on the specific model. This wide measurement range makes it suitable for various industrial applications, including gas separation, electronics manufacturing, and food packaging. For exact measurement capabilities, please refer to the product specifications of your specific model.

Q2: What type of output signals does the nitrogen purity analyzer provide?

A2: The nitrogen purity analyzer is equipped with a standard 4-20mA analog output, which allows seamless integration into industrial monitoring and control systems. Additionally, it features a relay contact output, enabling users to set upper and lower limit control points for automatic alerts and process adjustments. These outputs enhance the analyzer’s compatibility with automation systems and industrial data acquisition setups.

Q3: Is the nitrogen purity tester easy to install and operate?

A3: Yes, the nitrogen purity tester is designed for easy installation and user-friendly operation. It features a compact and lightweight design, making it convenient to mount in different industrial settings. The intuitive LCD digital display provides real-time nitrogen purity readings, ensuring clear and accurate monitoring. Additionally, the analyzer includes adjustable control settings, allowing users to configure alarm thresholds and output signals based on their specific process requirements.

Tips: What sensor technology does the nitrogen purity analyzer use?

The nitrogen purity analyzer utilizes an imported electrochemical sensor to measure the oxygen content in the sample gas, allowing for accurate nitrogen purity calculations. This sensor technology provides high sensitivity, fast response time, and reliable long-term performance. Additionally, the analyzer is designed to compensate for environmental factors, ensuring stable readings even in industrial conditions. Regular calibration helps maintain the sensor’s accuracy over time.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.