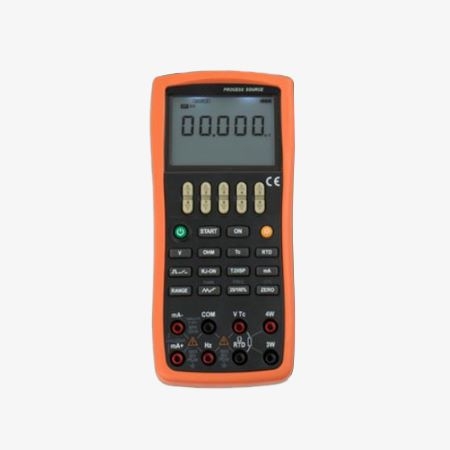

This SISCO multifunctional process calibrator has an open-source communication protocol features a large LED screen for multiple data displays, which can simultaneously show: DC current and% value, thermocouple, thermal resistance temperature and their corresponding division values, etc. It can also be equipped with high-precision temperature probes, with an accuracy of ± 0.2 ℃. It can output various process parameter signals to meet most of the on-site debugging and maintenance needs.

Characteristics of a multifunctional process calibrator

- The basic accuracy of the output of the multifunctional process calibrator is displayed as 6 bits.

- Output functions: DC voltage, DC current, ohms, analog transmitter, thermocouple, thermistor, frequency, pulse, switch quantity.

- When outputting DC current, it can provide 25% and 100% manual stepping, automatic stepping, and automatic ramp output functions.

- High precision automatic cold end compensation and temperature display in ℃ or below can be provided during thermocouple output.

Introduction of a multifunctional process calibrator

- Basic accuracy can reach 0.02%.

- Manual/automatic thermocouple cold end compensation setting.

- The process signal source has an open-source communication protocol.

- This multifunctional calibrator can output process parameter signals, meeting most of the on-site debugging and maintenance needs.

Applications

SISCO process calibrators are widely used in various industries, including manufacturing to ensure the accuracy of sensors in automated systems. Pharmaceuticals: maintaining compliance with strict temperature and pressure regulations. Energy and utilities testing electrical and pressure instruments in power plants and pipelines. Aerospace verifying flight instruments and environmental control systems. Food and beverage to ensure accurate temperature control in processing and storage.

Papermaking

Papermaking

Food

Food

Light industry

Light industry

Electric power

Electric power

| Model | SISCO-PC-VICTOR11+ | ||||

| Function | Range | Output setting range | Resolution | Accuracy | Notes |

| DCV | 100mV | -10.000~110.000mV | 1μV | 0.02+0.01 | Maximum output current 0.5mA |

| 1000mV | -100.00~110.000mV | 10μV | Maximum output current 2mA | ||

| 10mV | -1.0000~11.0000V | 0.1mA | Maximum output current 5mA | ||

| DCmA | 20mA | 0.000~22.000mA | 1μA | 0.02+0.02 | At 20mA, when simulating a transmitter with a maximum load of 1 KΩ resistor, the external power supply is 5-28V |

| OHM | 400Ω | 0.00Ω~400.00Ω | 0.01Ω | 0.02+0.02 | The excitation current is ± 0.5~3mA/excitation current is ± 0.1~0.5mA, and the accuracy does not include lead resistance |

| 4KΩ | 0.0000KΩ~4.0000KΩ | 0.1Ω | 0.05+0.025 | The excitation current is ± 0.05~3mA, and the accuracy does not include lead resistance | |

| 40KΩ | 0.000KΩ~40.000KΩ | 1Ω | 0.1+0.1 | The excitation current is ± 0.01mA, and the accuracy does not include lead resistance | |

| TC | R | 0℃~1767℃ | 1℃ |

0~100℃: 1.5℃ 100~1767℃: 1.2℃ |

The accuracy of ITS-90 temperature scale does not include the error of cold end compensation |

| S | 0℃~1767℃ | 0~100℃: 1.5℃ 100~1767℃: 1.2℃ | |||

| K | -200.00℃~1372.0℃ | 0.1℃ | -200.0~100.0℃: 0.6℃ -100.0~400.0℃: 0.5℃ 400.0~1200.0℃: 0.7℃ 1200.0~1372.0℃: 0.9℃ | ||

| E | -200.00℃~1000.0℃ | -200.0~-100.0℃: 0.6℃ -100.0~600.0℃: 0.5℃ 600.0~1000.0℃: 0.4℃ | |||

| J | -200.00℃~1200.0℃ | -200.0~-100.0℃: 0.6℃ -100.0~800.0℃: 0.5℃ 800.0℃~1200.0℃: 0.7℃ | |||

| T | -250.0℃~400.0℃ | -250.0~400.0℃: 0.6℃ | |||

| N | -200.00℃~1300.0℃ | -200.0~100.0℃: 1.0℃ -100.0~900.0℃: 0.7℃ -900.0~1300.0℃: 0.8℃ | |||

| B | 600℃~1820℃ | 1℃ | 600~800℃: 1.5℃ 800~1820℃: 1.1℃ | ||

| L | -200.0℃~900.0℃ | 0.1℃ | -200.0~0.0℃: 0.7℃ 0.0~900.0℃: 0.5℃ | ||

| U | -200.0℃~600.0℃ | 0.1℃ | -200.0~0.0℃: 0.7℃ 0.0~600.0℃: 0.5℃ | ||

| RTD | Pt100385 | -200.0℃~800.0℃ | 0.1℃ | -200.0~0.0℃: 0.3℃ 0.0~400.0℃: 0.5℃ 400.0~800.0℃: 0.8℃ | Using the ITS-90 temperature scale: 1. When the excitation current of Pt1Cu00, 50, and Cu10 is ± 0.5~3mA, and the excitation current is ± 0.1~0.5mA, an additional error of 0.5 ℃ is added. 2. The excitation current for Pt200, Pt500, and Pt1000 is ± 0.05~0.3mA, and the accuracy does not include lead resistance. |

| Pt200385 | -200.0℃~630.0℃ | -200.0~100.0℃: 0.8℃ 100.0~300.0℃: 0.9℃ 300.0~630.0℃: 1.0℃ | |||

| Pt500385 | -200.0℃~630.0℃ | -200.0~100.0℃: 0.4℃ 100.0℃~300.0℃: 0.9℃ 300.0~630.0℃: 0.7℃ | |||

| Pt1000385 | -200.0℃~630.0℃ | -200.0~100.0℃: 0.2℃ 100.0~300.0℃: 0.5℃ 300.0~630.0℃: 0.7℃ | |||

| Cu10 | -100.0℃~260.0℃ | 0.8℃ | |||

| Cu50 | -50.0℃~150.0℃ | 0.6℃ | |||

| FREQ | 100Hz | 1.00Hz~110.00Hz | 0.1Hz | ±2个字 | 1~11Vp-p square wave level accuracy ± 5% reading=0.5V, 50% duty cycle, load>100K Ω |

| 1KHz | 0.100KHz~1.100KHz | 1KHz | |||

| 10KHz | 1.0KHz~11.0KHz | 0.1KHz | |||

| 100KHz | 10KHz~110KHz | 2KHz | ±5个字 | ||

| PULSE | 100Hz | 1~100000cycles | 1cyc | ±2个字 | 1~11Vp-p square wave level accuracy ± 5% reading=0.5V, 50% duty cycle, load>100K Ω |

| 1KHz | |||||

| 10KHz | |||||

| SWITCH | 100Hz | 1.00Hz~110.00Hz | 0.01Hz | ±2个字 | Field effect transistor switch, maximum switching voltage/current: ± 28V/50mA |

| 1KHz | 0.100KH~1.100KHz | 1Hz | |||

| 10KHz | 1.0KHz~11.0KHz | 0.1KHz | |||

| 100KHz | 10KHz~110KHz | 2KHz | ±5个字 | ||

Details

Q1: What is a Process Calibrator?

A1: A process calibrator is a device used to test, calibrate, and troubleshoot process instrumentation such as temperature sensors, pressure transmitters, and electrical signal sources. By simulating and measuring various signals, process calibrators enable engineers and technicians to validate system performance.

Q2: What are the types of process calibrators?

A2: Multifunction Calibrators - Capable of handling multiple types of signals including voltage, current, resistance, and frequency. Temperature Calibrators - Used specifically for thermocouples and RTDs to ensure precise temperature measurements. Pressure Calibrators - Designed for testing pressure-based instruments and ensuring accuracy in fluid systems. Loop Calibrators - Primarily used for 4-20 mA control loops in industrial automation systems.

Q3: How does a process calibrator work?

A3: A process calibrator is a multifunctional test tool used in industrial settings to simulate, measure, and source various process signals to calibrate and troubleshoot instruments.

- Simulation (Sourcing Mode): The calibrator mimics a sensor or transmitter: For example, it can output a 4-20 mA signal to test a control system input. It can simulate a thermocouple or RTD to test temperature controllers.

- Measurement Mode: The calibrator measures signals coming from sensors or transmitters: It can measure the output of a 4-20 mA transmitter. Or it can read thermocouple or RTD signals to verify temperature readings.

- Loop Power Supply: Many calibrators can provide loop power (usually 24V DC) to power a 2-wire transmitter during testing—handy when you’re not connected to the control system.

- Documentation and HART/Fieldbus Communication (in advanced models): Some calibrators support automatic documentation of calibration results. Others can communicate with smart transmitters (e.g., HART protocol) to adjust or troubleshoot them.

Tips: When using the process calibrator, the following precautions should be taken:

- Safe operation: Prevent electric shock: Ensure good grounding of the equipment, avoid operating in humid environments, and be careful to avoid contact with exposed metal parts during operation. Avoid overload: The input signal should not exceed the device range to prevent damage. Prevent damage: In case of abnormalities (such as smoking, odor), immediately turn off the power and checkCorrect use Environmental requirements: Operate at appropriate temperature and humidity, avoiding strong magnetic fields, strong vibrations, and other interferences.

- Correct connection: Ensure good contact of the connecting wires, pay attention to the correspondence and polarity of the interfaces. Function and range selection: Select appropriate measurement functions and ranges according to requirements to ensure measurement accuracy.

- Maintenance: Regular calibration: Calibrate on time to ensure the accuracy of measurement results. Cleaning and maintenance: Keep the equipment clean and dry, and avoid using chemical cleaning agents. Storage environment: When not in use for a long time, store in a dry, ventilated, and non corrosive gas environment. Following these precautions can effectively ensure the accuracy and reliability of the process calibrator, and extend its service life.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.