The Izod tester uses advanced electronic control systems and high-precision sensors to accurately measure parameters such as energy changes and impact force of film materials during impact.

One-Button Impact Test: Simple, Fast, and Efficient

- The electronic control system can effectively reduce the impact of external interference on the test results, making the test data more stable and repeatable, providing a strong basis for material performance evaluation and quality control.

- The Izod pendulum impact tester has a fully automatic operation function. You only need to set the relevant test parameters on the operation interface. The operation is simple and convenient, which greatly improves the test efficiency.

- The impact testing equipment can perform low-energy impact simulation to evaluate the performance of the film in the case of a slight drop or a slight collision (such as the anti-fall property of packaging film), avoiding the overload damage caused by the excessive energy of traditional pendulum impact.

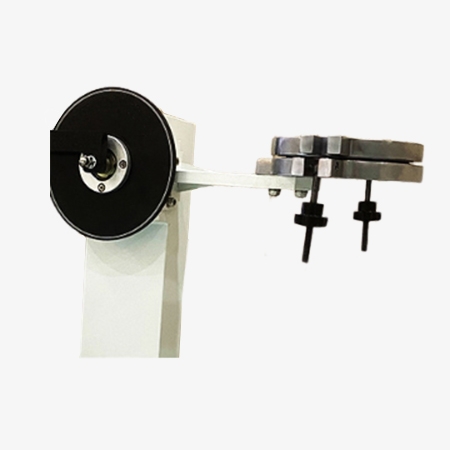

Adjustable Clamp to Meet Various Needs

- Izod impact machine adopts a touch operation mode to support various types of impact energy input.

- The sample holder can be installed on the fixture seat, and the height and position of the fixture seat can be adjusted according to the test needs.

- Izod testing machine uses precision casting, detailed polishing, and quality assurance.

Applications

Impact testers are suitable for impact resistance testing of various film materials, such as plastic film, composite film, paper-based composite film, aluminized film, metal foil, etc. It can also be used for impact testing of thin plates, packaging materials, etc., and can meet the testing needs of different materials in different industries.

Metal Film

Composite Film

Plastic Film

Nylon Plastic Film

| Model | SISCO-IT-ZW102601 |

| Maximum Cooling Capacity | 0~3J (6J adjustable) |

| Test Size | 100×100mm or Φ100mm |

| Exam Grade | Φ60mm, Φ89mm |

| Scale Size | 4, Φ25.4mm, R12.7*φ19mm (determinable) |

| Radius of Movement | 200mm |

| Difference in Ability | ±1% |

| Branching Rate | 0.01J |

| Electric Power Source | DC 12V, 60W |

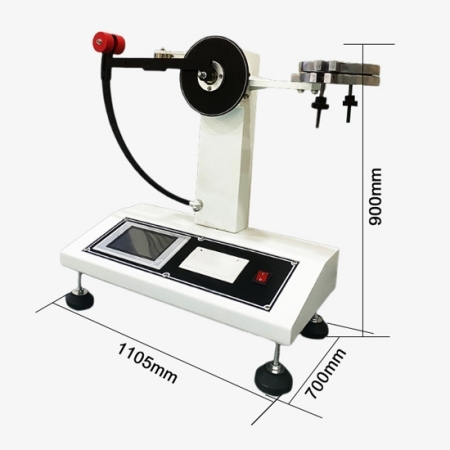

| Size | 110.5cm×70cm×90cm |

| Weight | 20kg |

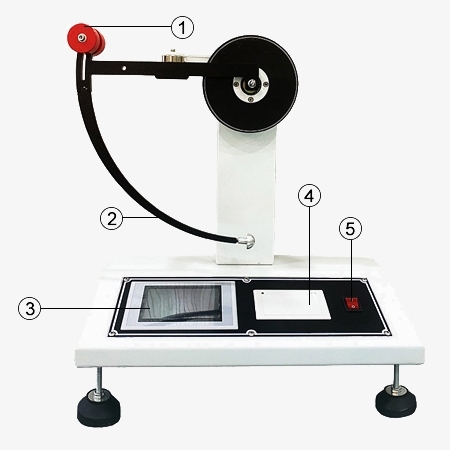

Structure Diagram

- Electromagnet

- Impact Hammer

- Touch Panel

- Micro Printer

- Power Supply

Q1: What is a Charpy Impact Tester?

A1: A Charpy tester is a device specifically used for Charpy impact tests. The Charpy impact test machine is mainly used to evaluate the toughness and fracture characteristics of metal materials under dynamic loads, especially in evaluating the low-temperature toughness of steel materials and the quality of welded joints. The working principle is mainly based on the law of conservation of energy and the energy change of an object when it is impacted instantly.

Q2: What is an Izod Impact Tester?

A2: An Izod impact strength test is a device used to perform an Izod impact test, which is used to evaluate the impact toughness of plastics, polymers, glass, and other non-metallic materials. The Izod impact test is similar to the Charpy impact test, but the placement and impact method of the specimen are different. A specimen with a specified shape, size, and notch type is clamped at one end, and the other end is used as a free end. Then, a pendulum of a specified height is used to hit the free end of the specimen once, and the work absorbed by the specimen when it breaks under impact is measured.

Q3: How to Use an Impact Tester?

A3: First, prepare the machine to ensure that the machine is in good working condition and check whether all parts are intact, including the pendulum, specimen fixture, measuring device, etc. Install the specimen correctly in the fixture of the tester. For the Charpy test, the specimen is usually placed horizontally; for the Izod test, the specimen is placed vertically with the notch facing the impact direction of the pendulum. Set the initial height of the pendulum according to the test standard to ensure that the pendulum has enough energy for the test when it is released. Release the pendulum and let it fall freely and hit the specimen. After the pendulum hits the specimen, record the final position of the pendulum or record the data through the automatic measurement system of the testing machine. Please note that different types of impact testers and different test standards may require specific operating steps and parameter settings. Therefore, before using the impact tester, the operating manual and relevant test standards provided by the manufacturer should be read and followed in detail.

Tips: Common Misunderstandings in Using Impact Testers

Impact testing machines are prone to misunderstandings during use due to improper operation or neglect of details. These misunderstandings not only affect the accuracy of the test results, but may also cause damage to the equipment. The size and shape of the specimen have a great influence on the test results. If the size and shape of the specimen do not meet the standard requirements, the test results may be inaccurate. The preparation process of the specimen will also affect the test results, such as the machining accuracy, surface roughness, heat treatment status of the specimen. The setting of the impact energy needs to be reasonably selected according to factors such as the material, size and test requirements of the specimen.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.