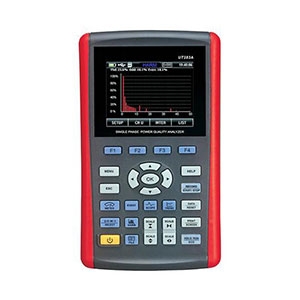

A power quality analyzer is an instrument used to measure and analyze power quality. Power quality is a particularly important parameter in industrial production and people's livelihood electricity consumption. Therefore, regular maintenance of the power quality analyzer can ensure its accuracy and precision and effectively improve the service life of the power quality analyzer. This article SISCO store will introduce the regular maintenance of the power quality analyzer, including cleaning, calibration, and maintenance.

1. Cleaning

The power quality analyzer is installed in a variety of on-site environments. It is easy to be contaminated by dust, oil and other debris during use, resulting in a decrease in the accuracy of the instrument. Therefore, during regular maintenance, the power quality analyzer must be cleaned first. The actual steps are as follows:

- Cleaning with anhydrous alcohol

an anti-static brush and soft cloth, and then place the power quality analyzer in a dry and clean place. Use the anti-static brush and soft cloth to clean the outer surface, display screen, interface, sensor and other parts. Be careful to use anhydrous alcohol for cleaning and avoid entering parts that should not be entered. - Cleaning with a handheld vacuum cleaner

Prepare a handheld vacuum cleaner, place the power quality analyzer in a dry and clean place, and use the vacuum cleaner to clean the inside of the power quality analyzer. - Brush cleaning

Use a soft brush to clean, and use a brush to clean hard-to-clean areas such as dust on the sensor.

2. Calibration

The accuracy and precision of the power quality meter must be calibrated regularly, otherwise it will affect the use of the instrument. Before using the power quality analyzer and after calibration, it is recommended to power on the instrument for testing to ensure that the instrument has no faults.

- Calibration accuracy

Calibration accuracy refers to the deviation between the instrument reading and the actual value. The greater the deviation between the instrument reading and the actual value, the lower the accuracy of the instrument. - Calibration method

The calibration of power quality analyzers is usually performed using a standard power supply. During the calibration process, the instrument should be operated in accordance with the requirements of the instrument manual, and multiple steps such as power calibration, voltage calibration, and current calibration should be performed in sequence according to the calibration requirements. During the calibration process, the calibration time and calibration personnel for later reference.

3. Maintenance

In order to ensure the service life of the power quality analyzer and improve its accuracy and stability, in addition to regular cleaning and calibration, it is also necessary to maintain and inspect the instrument. The practical methods are as follows :

- Maintenance measures

Before using the power quality analyzer, the power quality analyzer should be preheated. When using the power quality analyzer , you need to pay attention to protecting the various interfaces of the instrument, avoid plugging and unplugging the traction line too quickly, and avoid bending or twisting the traction line when using it. If you need to stop using it for a short time during use, you should turn off the power quality analyzer in time to prevent the instrument from being in a high temperature state for a long time. - Troubleshooting

During use, if the power quality analyzer is found to have a fault, it should be checked and handled in a timely manner. When a fault occurs, the fault cell indicator light, network connection status, etc. should be checked, and experienced technicians should be notified in a timely manner to handle it.

Power quality analyzers are extremely important power testing equipment that can improve power quality and reduce faults on power lines. During regular maintenance, power quality analyzers need to be cleaned, calibrated, and maintained. Only in this way can the accuracy and precision of the instrument be improved, the service life of the instrument be extended, and the power quality analyzer can better serve industrial production and people's livelihood electricity use.