Gloss refers to the ability of the material surface to reflect light under specified conditions. It has the property of direction-selective reflection, usually referring to the ability of the mirror to reflect light. It is related to the smoothness of the object surface, the incident angle of light, and the intensity of light. The surface of an object with high gloss is usually very smooth and can reflect more light, because the reflection of light on a smooth surface is more regular than on a rough surface, making the direction of the reflected light more concentrated and the intensity of the reflected light greater. Gloss is a different concept from the finish and roughness in the machining industry. It is expressed by multiplying the reflectivity of the sample relative to the standard surface in the mirror (regular reflection) direction by 100, that is, G=10OR/R.

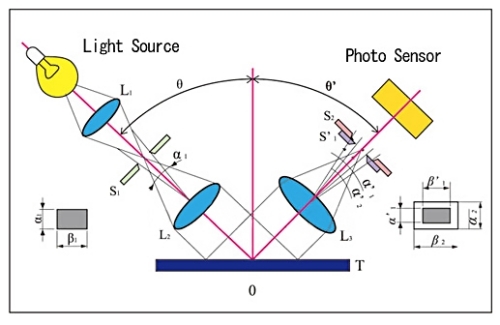

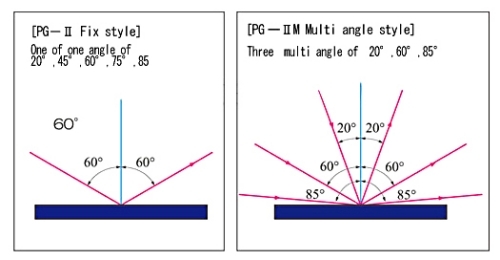

A gloss meter, also known as a gloss meter, is a device used to measure the gloss of the surface of a material. The gloss type can be divided into three types: high gloss, medium gloss, and low gloss. According to the angle, it can be divided into 20°, 45°, 60°, 75°, 85°, etc. At present, the 60° angle is commonly used on the market, and there are also two-angle and three-angle gloss meters.

Gloss meters are used to measure the gloss of various materials, including decorative materials, plastic materials, ceramic products, stone products, bamboo and wood products, leather products, film and paper, automobile maintenance, molding molds, metal coatings, etc. It can not only measure the gloss of materials but also be used to characterize the surface roughness and wear of plastic products. Therefore, this wide applicability makes gloss meters play an important role in many industries such as chemical raw materials, coating manufacturing, aerospace industry, automobile industry, shipbuilding industry, electronics industry, electrical industry, IT communication, etc.

Advantages of Gloss Meter

- The advantages of gloss meter are mainly reflected in the following aspects:

High-precision measurement. Modern gloss meter adopts advanced optical systems and precise mechanical structures, which can achieve high-precision measurements of reflected light, and provide accurate and reliable data support for scientific research and industrial production. - Multi-angle measurement. By changing the angle between the incident light and the measurement surface, the gloss meter can measure the gloss of the material at different angles, so as to obtain more comprehensive and richer gloss information.

- Easy operation. The modern gloss meter is usually equipped with a user-friendly operation interface and intelligent control system, and many gloss meters are lightweight and easy to carry, which allows them to measure in different locations without being restricted by the laboratory environment. This makes the measurement process simpler and faster, and even non-professionals can easily get started.

- Widely applicable: The gloss meter is suitable for gloss measurement of many different materials, such as metal, plastic, coating, paper, etc., and is widely used in automotive, aerospace, construction, furniture, and other industrial fields.

These advantages make gloss meters a very important tool in industrial production and quality control. It has become an important tool for evaluating the surface characteristics of materials in many industries. You can buy more styles of high-quality gloss meters in the SISCO online store.

Daily Maintenance Methods for Gloss Meters

To ensure the accuracy of the gloss meter and extend its service life, daily maintenance is very important. Here are some specific maintenance steps:

- Choose a suitable storage environment. Avoid direct exposure to strong light, and also avoid moisture and extreme temperatures. Strong direct light, contact with moisture, and exposure to high humidity may affect the optical components of the instrument, thereby affecting the performance of the instrument. During non-use, the gloss meter and its accessories should be stored in a dry, clean, temperature-appropriate environment and placed in a special package to protect the instrument from damage.

- Clean the optical lens. If it is found during the calibration process that the calibration value of the standard plate cannot be reached even if the calibration knob is turned to the end, the optical lens may be contaminated. At this time, you can wipe the lens with a little anhydrous alcohol with lens paper to remove contaminants.

- Keep the standard plate clean. The gloss meter is usually equipped with at least one standard plate for calibration. These standard plates should be kept clean and avoid touching the surface with your fingers to prevent stains from affecting the measurement results. If there are stains on the surface, you can wipe it gently with lens paper or anhydrous alcohol.

- Calibrate regularly. Although some gloss meters are designed to be stable and do not require frequent calibration, it is recommended to recalibrate after 2 hours of continuous use to ensure the accuracy of the measurement.

- Pay attention to battery management. The reading of the gloss meter may begin to decline when the battery voltage drops below 0.8V, so the battery should be replaced in time. When not in use for a long time, the battery should be removed to avoid damage caused by battery leakage.

- When carrying or transporting the gloss meter, the original box or a dedicated carrying box should be used to ensure the safety of the instrument. Avoid shock and vibration. The gloss meter is a precision optical instrument and should be protected from severe shock and vibration, which may cause internal damage or displacement of optical components.

Following the above maintenance methods can help you better maintain the gloss meter and ensure that it provides reliable measurement results for a long time. Depending on your specific needs and budget, you can choose from a wider range of test and measurement equipment from the SISCO online store.