Turbidity meters are essential tools for monitoring water quality in various industries, including environmental monitoring, wastewater treatment, food, and beverage. These meters measure turbidity for drinking and surface water. Calibration ensures the accuracy of turbidity measurements, providing reliable data for quality control. Here’s a step-by-step guide on how to calibrate your portable digital water turbidity meter 1000 ntu or benchtop turbidity meter effectively.

Working Principle of a Turbidity Meter

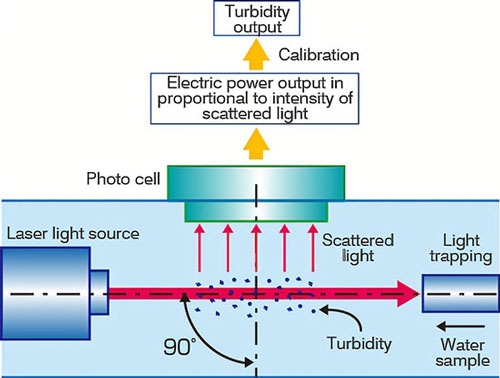

Before detailing the calibration procedure, it is helpful to understand how a turbidimeter works. Turbidimeters typically use the principle of light scattering, which means that when light passes through a liquid containing suspended particles, the particles scatter the light. Turbidimeters measure the intensity of the scattered light and convert that intensity into a turbidity value.

Preparation for Calibration

Before starting calibration, make sure you have the following items and conditions ready:

- Standard Turbidity solutions: These have a known turbidity value, usually expressed in NTU (Scattered Turbidity Units), and are used to calibrate the turbidimeter.

- Clean Sample Bottles: Containers for standard solutions and samples, make sure they are clean and free of scratches.

- Distilled or Deionized Water: For cleaning the sample bottle and zero calibration.

- Turbidimeter User's Manual: Contains specific calibration procedures and operating instructions for the instrument.

Calibration Procedure

1. Zero Calibration

Zero calibration is the process of ensuring that the turbidimeter reads zero in a turbidity-free medium.

- Clean the sample container and fill it with distilled water.

- Place the container with distilled water into the measuring chamber of the turbidimeter.

- Adjust the turbidimeter until the reading shows zero.

2. Standard Solution Calibration

Calibrate with standard solutions of different concentrations to ensure the accuracy of the instrument at different turbidity levels.

- Select one or more standard solutions with known turbidity values.

- Pour the standard solution into a clean sample container.

- Place the container in the turbidimeter and record the turbidity meter reading.

- Compare the reading to the actual turbidity value of the standard solution and adjust the calibration of the turbidimeter as necessary.

3. Multi-point Calibration

To improve the accuracy of the measurement, it is recommended to carry out multi-point calibration.

- Perform multiple calibrations using different concentrations of standard solutions.

- Repeat the calibration procedure for each concentration of solution and adjust the turbidimeter until the readings agree with the standard values.

4. Verify Calibration

After calibration is complete, verify the accuracy of the calibration using another set of standard solutions.

- Select a standard solution not used for calibration to verify.

- Measure the turbidity of the verification solution and compare it to a known turbidity value.

- If the reading is inaccurate, it may be necessary to recalibrate the turbidimeter.

Calibration Solution Preparation

Preparing a standard turbidity solution is a critical step in the calibration process. These solutions are usually supplied by specialized calibration solution suppliers or can be prepared in-house according to international standards. The following are some common types of calibration solutions and preparation methods:

- Formalin Standard Solution: This is a commonly used calibration solution with a known and stable turbidity value.

- Hydrazine Sulfate Standard Solution: This solution is suitable for calibration in the high turbidity range.

- Formazine Standard Solution: This solution provides a wide range of turbidity values and is suitable for a wide range of calibration needs.

Precautions

There are several key points to keep in mind when performing calibration:

- Sample Temperature: Ensure that the sample temperature is close to room temperature, as temperature variations may affect the turbidity reading.

- Sample Bottle Cleanliness: Clean the sample bottle before and after use to avoid cross-contamination.

- Avoid Air Bubbles: Avoid air bubbles in the sample during the measurement process, as this can affect the scattering of light.

- Regular Calibration: Calibrate the turbidimeter regularly according to the frequency of use and the manufacturer's recommendations.

Maintenance after calibration

Once calibration is complete, proper maintenance will ensure that the turbidimeter remains accurate over time.

- Cleaning and Storage: Clean the turbidimeter after use and store it in a dry, light-proof environment.

- Record Calibration Data: Record the date of each calibration, the calibration solution used and the calibration results for easy tracking and quality control.

- Periodic Inspection: Check the performance of the turbidimeter periodically to ensure that it continues to provide accurate measurements.

Conclusion

Accurate calibration is key to ensuring that your turbidimeter provides reliable data. High-quality test and measurement devices are purchased to improve accuracy, efficiency and productivity in any laboratory or industrial environment. By following the steps and precautions outlined above, you can ensure that your turbidimeter will provide accurate measurements in a variety of applications. Regular calibration and proper maintenance not only improves the accuracy of your measurements, but also helps to extend the life of your instrument, resulting in long-term benefits for your business.