The horizontal tensile testing machine has a manual and automatic control operation mode. It can be operated by computer automatic control or manual operation. The operation interface is simple and intuitive, easy to master, and the operator can operate proficiently after simple training.

High-precision Testing Requires Only Simple Operation

- Adopt high-precision, full-digital speed regulation system and precision reducer to drive precision screw pair for testing, realize large-scale adjustment of test speed, low noise and smooth operation during the test process.

- Touch screen operation mode, LCD real-time display. The display interface can display the test method selection interface, the test parameter selection interface, test operation and result display interface, which is convenient and fast.

- Adopt a double guide rod structure, good stability, and a wide application range.

Good Safety, Test Results can be Directly Output

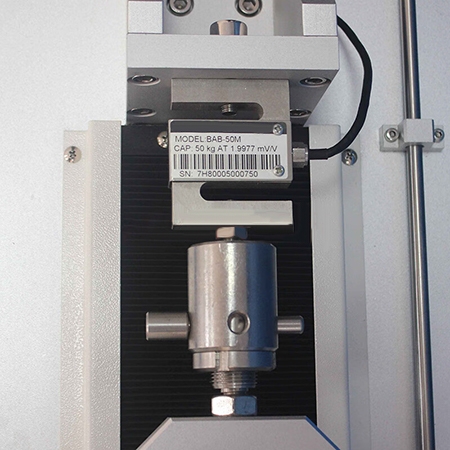

- The universal joint adopts a cross pin structure and has a swing angle limiting function. On the one hand, it is convenient for sample clamping and ensures the concentricity of the test. On the other hand, it eliminates the influence of irregular samples on the sensor.

- The horizontal tensile testing machine has good safety performance and can adjust the speed of the crossbeam when clamping the sample. It has overcurrent, overvoltage, overload, and other protection devices.

- The optional microcomputer interface can be connected to an external microcomputer to control the test process and store and print data.

Applications

A tensile tester is a commonly used material testing equipment used to evaluate the mechanical properties of materials under tension. A tensile testing machine can be used in the research and development of new materials to test their tensile strength, yield strength, elastic modulus, elongation at break, and other mechanical properties. In various manufacturing industries, such as metal processing, plastic molding, rubber manufacturing, fiber reinforced composite material production, etc, the performance of raw materials and finished products. It can also be used to test the mechanical properties of products such as medical implants and surgical instruments to ensure their safety and functionality during use. It is used to test the tensile strength and elongation of textile and clothing materials, and can also ensure the comfort and durability of the product.

Electronic Appliances

Industrial Plastics

Laboratory

Auto Parts

| Model | SISCO-TT-HTLI50 |

| Style | Single Arm |

| Maximum Test Force | 5, 10, 50, 100, 200kg available |

| Range | 1~50kg |

| Test Force Accuracy | ±0.1% |

| Displacement Resolution | 0.1mm |

| Displacement Measurement Accuracy | ±1% |

| Test Stroke | 600mm |

| Displacement Speed Control Range | 0.5mm/min~500mm/min |

| Displacement Speed Control Accuracy | ±1% |

| Testing Machine Level | 0.5 level |

| Deformation Indication Error | ≤±0.5% |

| Protection Function | The testing machine has an overload protection function. |

| Power Supply | 220V,50Hz |

| Dimensions | 460mm×500mm×155mm |

| Weight | 70kg |

Q1: Does the Test Speed of the Tensile Tester Affect the Test Results?

A1: The test speed of the tensile tester has a significant effect on the test results. Test speed refers to the rate at which the specimen is stretched during the tensile test, usually expressed in millimeters per minute (mm/min) or strain rate (such as percentage change per second).

Q2: How to Choose the Appropriate Test Speed Based on Material Properties?

A2: When choosing the appropriate test speed for material testing, multiple factors need to be considered, including the material's mechanical properties, strain rate sensitivity, test standards, and experimental purpose.

Q3: How to Use a Tensile Tester?

A3: First, prepare the machine to ensure that the machine is in good working condition and check whether all parts are intact, Install the specimen correctly in the fixture of the tester. Set the initial height of the pendulum according to the test standard to ensure that the pendulum has enough energy for the test when it is released. Release the pendulum and let it fall freely and hit the specimen. After the pendulum hits the specimen, record the final position of the pendulum or record the data through the automatic measurement system of the testing machine.

Tips: Daily Maintenance of the Tensile Tester

After each use, wipe the outer shell of the tensile machine with a clean, soft cloth to remove dust and stains. For precision parts such as sensors, special cleaning tools and detergents can be used for careful cleaning. When not in use for a long time, the tensile machine should be covered with an outer cover to prevent dust from entering the instrument, and a clean cotton cloth with a little anti-rust oil should be used to wipe the surface of the tensile machine fixture and non-painted parts to prevent rust. Add an appropriate amount of lubricating oil to the transmission parts of the tensile machine to reduce wear and ensure smooth operation of the equipment.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.